-----

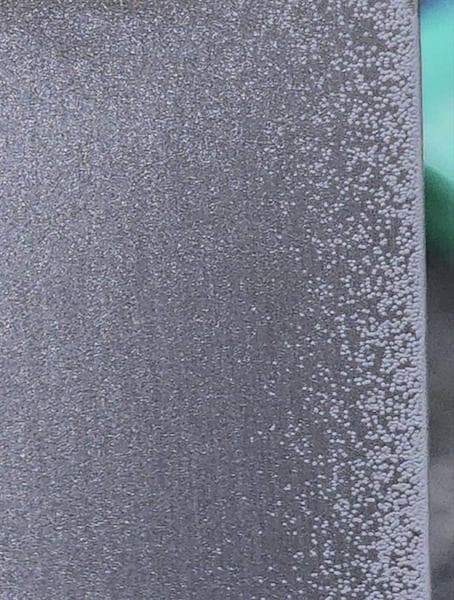

Random growths dot on hard Chrome plating HCD area

Quickstart:

Readers who are unfamiliar with chrome plating or who don't understand how "hard chrome" differs from decorative chrome may wish to start with our "Intro to Chrome Plating".

Regarding the 'barium carbonate' mentioned in the thread: chrome will not plate without a 'catalyst' present in the solution in a carefully controlled ratio, neither too high nor too low. The most common catalyst is sulfate (SO4 -2) at a ratio of about 1 part per 100 parts of chrome. If the ratio is too high, the addition of barium chromate will reduce it.

Chrome plating will "burn"⇦ huh? if the "current density"⇦ huh? is too high; parts being plated will usually have different current density at different spots on the part; there will be some HCD (high current density) areas.

Q. I have issues with hard chrome plating:

We have plated shock absorber cylinders

1. surface area 3955 cm2

2. at 1700 A, 43 a/dm2

3. temperature 55-58 C

4. Metal contamination 2 g/l

5. solution within control range

We have plated at this current for this part for 3 years.

However, this Rather growths white dot suddenly found on high current area (top & bottom). After we transfer solution out for bath maintenance and chemist adjust sulfate ratio with Barium carbonate. (just FYI, after analyzed the ratio still in range).

What is the cause of the defect? Has anybody ever found this defect?

Many people think of high current, but the rectifier was just calibrated and we've used this intensity and fixed it for 3 years.

- Bangkok, Thailand

June 29, 2025

A. Sarun,

I saw the part' picture looks like chrome burn at HCD area

check the chrome ratio, should be 1:100

check chrome concentration and temperature

maybe current is too high

try to put bleeder both sides of the rack

Popatbhai B. Patel

electroplating consultant - Roseville, Michigan

September 1, 2025

Q, A, or Comment on THIS thread -or- Start a NEW Thread