-----

Why Anodizing Uses a Hollow Copper Work Bar

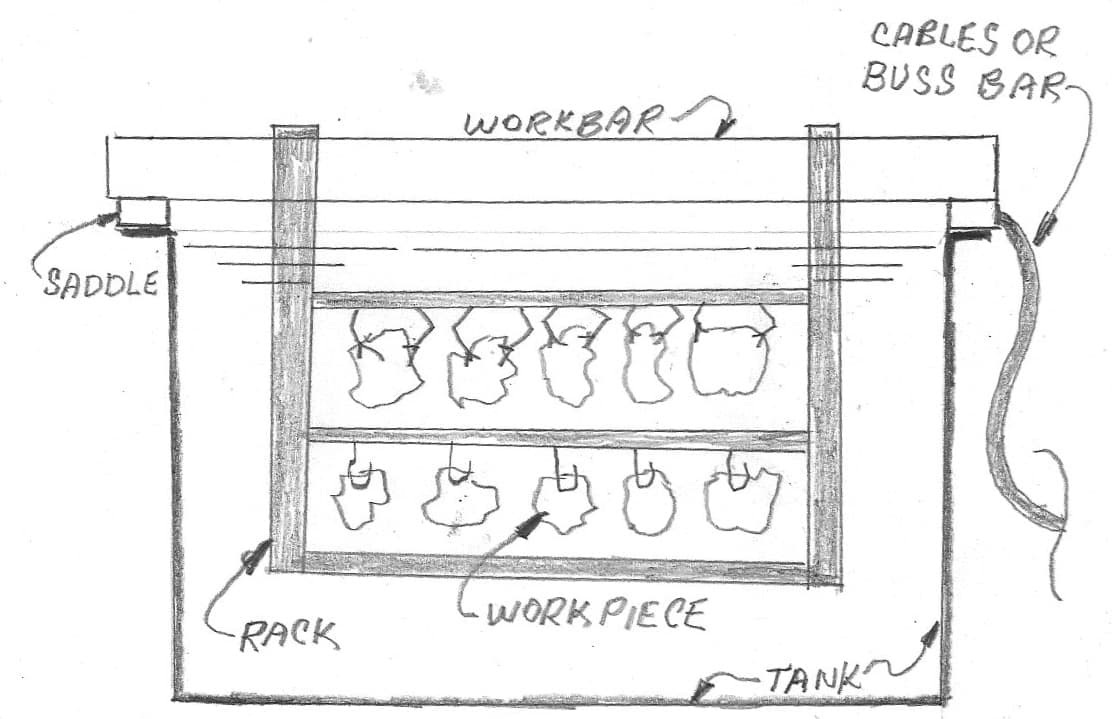

In production anodizing and plating, it is usual to suspend one or more plating racks from a copper bar or aluminum & copper structure that spans from one side of the tank to the other. This bar is often called a work bar or flight bar.

The tank is equipped with copper or brass contacts (often called saddles or v-blocks) mounted on the rims of the tank and bussed to the power supply. The bar sits down on these saddles. The bar carries the anodizing or plating current from the saddles to the racks; the racks in turn are conductive, carrying the current to the workpieces.

Q. Curious as to whether it matters if a copper flight bar for anodizing work is hollow?

That is to say, if the copper flight bar is like a pipe, but with closed ends, versus a solid piece of copper all the way through, will this potentially affect anything like carrying capacity?

I've usually seen solid pieces of copper or aluminum for flight bars.

Employee - Illinois

July 1, 2025

Readers are welcome to browse this site anonymously!

-- but its main purpose is worldwide camaraderie through sharing,

so readers wanting that might not engage with anonymous posters.

A. Hi Matthew

The DC current used in anodizing and plating runs through the conductor, not on its skin as in some AC applications. So the reason for using a hollow bar is because more strength can be gained from a hollow tube than from a solid bar of the same weight.

For plating and anodizing purposes, a rule of thumb is that the current carrying capacity of copper is 1000 Amps/sq.in, and 500 Amps/sq.in. for aluminum.

But the work bar must also be strong enough for the span and the weight of the racks. Often this means that a hollow tube meets the load carrying and current carrying needs better than a solid bar; it's not unusual.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q, A, or Comment on THIS thread -or- Start a NEW Thread