-----

Black spots /shadow on anodized aluminum corners

Anodizing ⇦ huh? offers quite good "throwing power" (the ability to coat the whole surface rather uniformly) because an anodized surface is insulating, which tends to divert the current to areas which are not yet coated with anodizing. So uniform coverage / uniform thickness is less of a problem than in electroplating processes.Q. We have 6061 aluminum product presenting shadows or black spots areas, most commonly on the bottom plate of product, in the corners of it.

Product is previously glass beaded, but the defect is visible only after anodize process

Roberto FloresEmployee - Monterrey, Mexico

June 10, 2025

Treatment &

Finishing of

Aluminium and

Its Alloys"

by Wernick, Pinner

& Sheasby

on eBay or Amazon

or AbeBooks

(affil link)

A. Hi Roberto

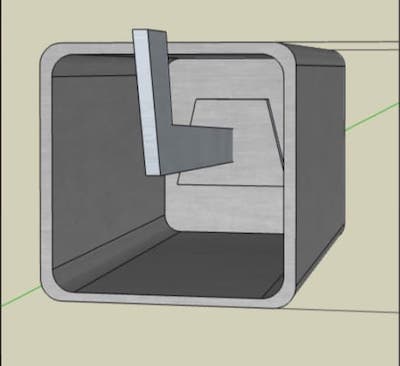

Unless I'm misunderstanding the pics, that appears to be a fairly complicated box-shaped weldment.

The first question is whether all of the pieces of the weldment are the same (6061) alloy -- if not, that can be a serious problem.

Although anodizing has quite good throwing power, it is not unlimited, so I think you should measure the thickness of the dark areas as well as a few other spots. Pictures of the whole component, including how it is racked/fixtured would be very helpful because it is easy to guess wrong about such things, and entrapped air or carried over solution can cause problems. Are there any auxiliary cathodes reaching into rhat box? I have no sense no scale unfortunately.

The first pic looks like you are shining a light into the box?

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Hi Ted

As you well mention, it is the bottom of a box-shaped chamber. The alloy material is the same on top and side walls of it.

We measured thickness of the surface on good finished areas and "shadowed" areas but values are quite similar. Roughness was measured but our instrument has no capacity to read too-rough areas, beyond 180 RMS.

I am attaching pictures of macro zoom of the affected area and overall product.

Much appreciated your time and kind support

Roberto FloresEmployee - Monterrey, Mexico

June 12, 2025

A. Hi again Roberto,

Presumably you tilt the bottom end of the box up after you remove it from each tank to assist in drainage?

If I understand your pics I have to acknowledge that I haven't personally seen a part of that size and complexity anodized. Still, it seems hard to attribute the darkening in the corners to anything other than the current distribution, suggesting that improving the shape of the internal cathode to better comply with the item you are anodizing should help. If the auxiliary cathode were to end in sort of an X shape reaching towards the four corners of the bottom plate I think it would help.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q, A, or Comment on THIS thread -or- Start a NEW Thread