-----

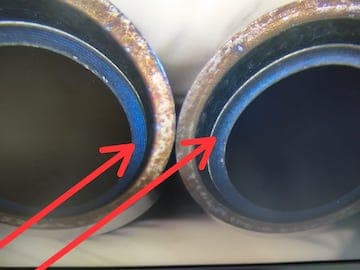

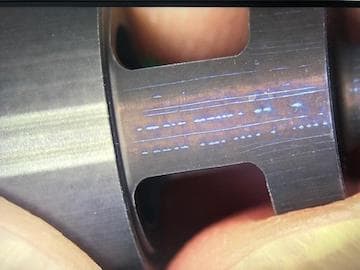

Blueish discoloration on hard anodized parts

April 11, 2022

Q. Hello

I have issues with my hard anodized parts.

Thickness is between 35-45 µm.

No sealing is being used.

The hard anodizing dryer is located beside spin chip area where oil mist is around.

We are only having this problem recently. Can anyone help with this matter?

- Johor Bharu Malaysia

A. Apparently the oil mist is getting into the pores, worse in the lower current density area where then pores are slightly larger.

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

April 16, 2022

April 17, 2022

![]() Thanks for the reply.

Thanks for the reply.

Q. We test run on another anodizing line.

Which is far away from the spin chip area.

But still we have the bluish colour.

Can suggest how to improve this visual defect?

Currently those cosmetic defects are accepted and released to end customer. Even washing on the parts could not eliminate the issue.

It can be wiped off with rubbing and IPA in the ID of the parts.

- Johor Bharu Malaysia

A. Hi Afiq. I think Robert's reply implied that a blue discoloration like this is not a known defect in hard anodizing. Therefore the chance that the alloy or something out of spec in the anodizing process, is the cause of the problem sounds extremely unlikely. On top of that, you didn't have the problem until recently and it's occurring on two distinct anodizing lines :-)

Please tell us the alloy and we can research whether there is anything special about it. But if you don't accept that the problem is in the operating environment rather than the alloy or the anodizing process, the only way forward would be to get some material from a different supplier and see if the problem persists, and for the supplier to ship his material to a different shop and see if the problem persists there. The environment in your shop or that the parts are exposed to before they get to you is causing the problem, and my bet is your shop rather than before you receive the material. Best of luck!

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

April 2022

Q, A, or Comment on THIS thread -or- Start a NEW Thread