-----

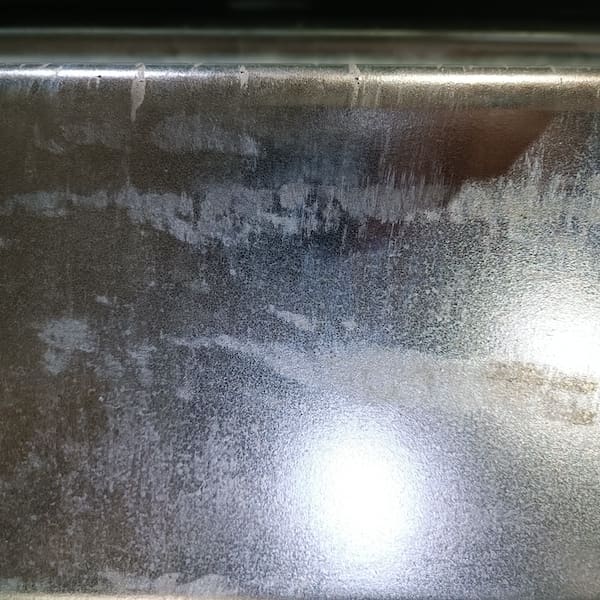

White patches on new hot dip galvanized poles, guardrails

March 14, 2022

Q. Hi,

After directly hot dip, found white patches on products.

Anyone can help me?

Thanks

PJ Singh- Klang, Selangor

A. It looks like "wet storage stain" sometimes also called "white rust". It's a mixture of zinc oxide and zinc carbonates and usually forms when new HDG is stored wet.

Geoff Crowley, galvanizing consultant

Crithwood Ltd.

Bathgate, Scotland, UK

March 21, 2022

⇩ Related postings, oldest first ⇩

September 5, 2021

Q. Please tell us that what is the reason for these white patches on new hot-dip galvanized poles? Whether it shall be the cause of rejection or we could accept it?

Thanks

Shahzad Khan- Dubai UAE

September 23, 2021

There looks (from the photos supplied) to be two different issues here. The two left pictures look more like aerosol spray sometimes used by galvanizers to repair small "holidays" (bare patches) in the coating, but unfortunately often used as a form of cosmetic to improve the finish. It looks OK on day one, but after some time when the real galvanizing has weathered, a colour difference appears. This aerosol paint usually has aluminium in it, sometimes some zinc (ISO1471 demands a high % Zn in the dry film), often non-compliant with the standard. So in these 2 pictures it looks like repair paint that didn't weather the same as the zinc. The standard rules on what size bare patch can be repaired are about the size of a medium money coin, quite small. Bigger than that and it should be re-galvanized. But the standard doesn't address random unnecessary painting with aluminium paint. I'd challenge them that you ordered HDG, not painting!

In the right picture it looks like a deposit from a chrome based quench/passivation tank. The slightly yellow colour, with the small circular spots are the signs. This isn't allowed by the ISO standard. It should have been removed by the galvanizer, and could have been done by light sanding, wire brushing etc, and much easier done when fresh. I'd reject that and ask them to remove the staining. It's aesthetic, not functional, in that the corrosion protection will still be there. But galvanizing isn't a "beautiful" coating at the best of times, so a pity to make it worse!

Geoff Crowley, galvanizing consultant

Crithwood Ltd.

Bathgate, Scotland, UK

Q, A, or Comment on THIS thread -or- Start a NEW Thread