-----

Hot-Dip Tinning Problems & Solutions

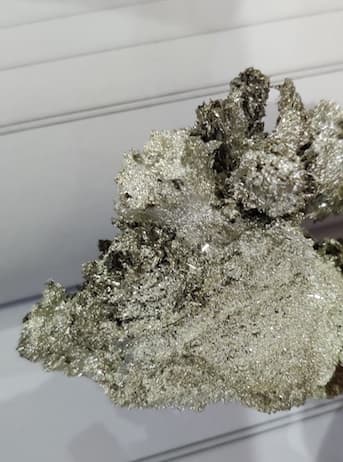

Q. DURING HOT TINNING I AM GETTING HARD TIN CRYSTALS IN THE MOLTEN POT WHICH DO NOT MELT, AND REDUCED PRODUCTION AND INCREASED PRODUCTION COST.

PLEASE TELL ME WHAT TYPES OF CRYSTALS THEY ARE AND WHAT IS THE METHOD TO REDUCE THEM.

RAKESH JAINOWNER - NEW Delhi, India

August 25, 2021

A. I have no experience in hot dip tinning or any related technology. But problem faced by Rakesh Jain is interesting. Here is my guess as to what could be happening. As winter approaches in higher latitudes lakes start freezing. It is a gradual process with water and ice coexisting for long periods. One can also see this happening in deep freezers in refrigerators. Probably something similar is happening in the hot tinning bath of Rakesh jain. When you dip a cold object in the hot bath the temperature of the bath drops. If the initial temperature was not high enough and heating rate is much lower than cooling rate, molten tin would solidify forming crystals. I think he needs to increase the heating power and temperature of the bath. Experienced would be better.

H.R. Prabhakara - ConsultantBangalore Plasmatek - Bangalore Karnataka India

Q. Thanks for yours suggestion, H.R.Prabhakara Ji

As I am Tinning copper wire, which has a temperature about 200 °C before going to Tin Tub and even I did not apply any chemical on bare copper wire.

As per your suggestion I increased the tin temperature to 280 °C It still exists. It is something else -- maybe copper tin alloy which I want to retard.

With regards,

OWNER - NEW Delhi, India

Q. I work as an engineer for a company and we are also having the exact same issue while tinning copper wire. I believe it is a Tin/Copper Dross that precipitates out and settles to the bottom but could be wrong. Does anyone know what causes this or how to reduce this?

Greg FulkEmployee - Du Quoin, Illinois

December 5, 2024

Q, A, or Comment on THIS thread -or- Start a NEW Thread