-----

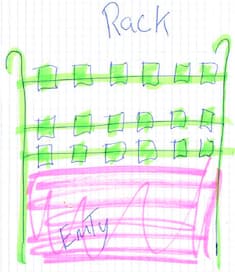

Okay to anodize small loads and largely empty racks?

Q. We are starting up a production line for anodize and we are designing the racks; I have designed a rack that can hold 200 parts, now we are informed that we have to anodize 50 at the time, due to our customer's flow. Is it important that the parts is evenly distributed at the tank/rack, or is ok that we only have parts at the top 30-40%

Poul Slot Mikkelsen- Vildbjerg Denmark

March 18, 2021

A. Hi Poul. If you were electroplating this would be a very serious problem because there would be so much anode area feeding the bottom of the rack that the bottom row of parts, especially their lower edges, would get much too much thickness. Because anodizing is an insulating film your problem will be much less severe; I don't think it will actually be a practical problem, but hopefully some highly experienced anodizers will correct me if I'm wrong.

Hopefully volume will soon be increased because you'll probably find that operating an anodizing line at 25% of its capacity is not economically viable in the long run :-(

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

March 2021

A. Cramming your parts in one area of your rack can only lead to problems. And the problems may be worse if you only use the top of the rack. Evenly spread out parts is the way to go, and dummy plates/parts in the empty areas might also be necessary.

Drew Nosti, CEF

Anodize USA

Ladson, South Carolina

March 21, 2021

A. The two racking methods will not cause obvious difference, because sulfuric acid have a great fluidity, you will not feel obvious difference on each position in one part indeed, so racking location don't need more focus on. however if the part is too big or distance of two parts is too close that maybe disturb thickness uniformity

Ryan Chao- Wuxi China

March 27, 2021

Q, A, or Comment on THIS thread -or- Start a NEW Thread