-----

Alkaline or High Dielectric Anodizing of Aluminum

Q. I'm working on a capacitive sensor that uses the inner surface of an aluminum tube as one half of a capacitor, and I'm looking for the highest dielectric constant and thinnest coating I can apply to it. Tube is ~1" ID x 1.25" OD and <6 inches long.

The working voltage is only 5 volts so any realistically feasible coating will have sufficient breakdown voltage if it isn't patchy or ultra porous. Wear resistance is also not a concern since it will see negligible friction and high but uniform pressure (<200 psi for sure, likely <50 psi) in use. I want to maximize the capacitance of this surface with another conductor pressed against it. To do so I want to maximize the dielectric constant of the coating material and minimize the coating thickness while avoiding uncoated spots.

Does anyone on here know of high-K coatings applied by electroplating or another reasonably accessible process? The default option is normal aluminum anodize, because alumina has k ~= 10, but I would really love to get something like barium strontium titanate with 10-100x higher values if it's an existing process I can pay a few hundred bucks for instead of a green-field process development situation. I'm also open to changing the tube material if there's a great coating that works better on steel, copper, titanium, etc.

Thanks!

-Nick

- Los Gatos / California

January 4, 2021

A. As for good voltage breakdown of Anodizing:

1. Using hot DI seal rather than Nickel seal;

2. normal sulfuric acid anodizing, VB hardly higher than 600V/mil and for oxalic acid anodizing, VB hardly higher than 800V/mil;

3. By special means the VB of anodizing could go as high as 1200V/mil.

John hu

- Singapore

January 6, 2021

⇩ Related postings, oldest first ⇩

Q. Hi Guys,

I am looking for some information on anodizing aluminium in an alkaline solution rather than an acidic solution to compare electrical properties.

I have been able to track down limited information on anodizing Mg and its alloys at different voltages but no performance results.

This is an early stage enquiry and possibly the process will not be suitable for commercial environments.

CPS Ltd - Dublin, Ireland

October 23, 2019

A. Bill,

Although we have not tried aluminum anodizing in alkaline solutions, we do hard anodizing in very mild acidic solutions in temperatures close to 50 °F or 10 °C.

adv.

No special refrigeration required in comparison to standard aluminum anodizing, where the processing temperature must be below zero for good hard anodizing. Anodized surface looks like ceramic.

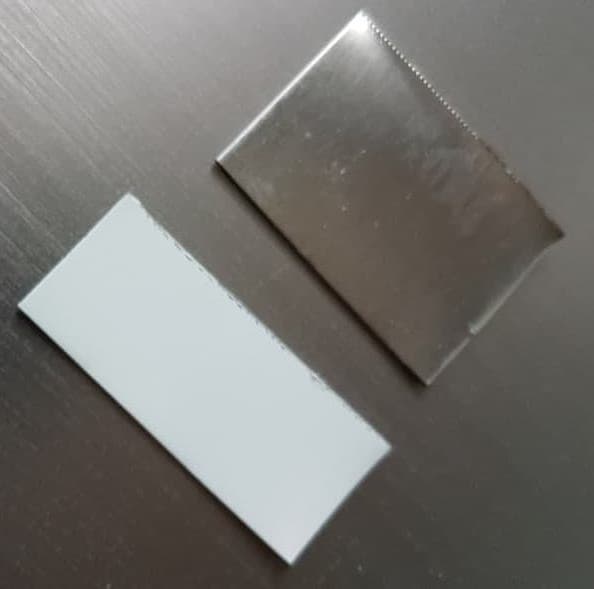

The surface hardness is like corundum. Nothing can be more durable. I have included the images of aluminum before and after.

Anna Berkovich

Russamer Lab - Pittsburgh, Pennsylvania

(ed. update July, 2025: sorry, Anna has retired)

Q. Thanks for that Anna,

Does that mean you have a level of Oxalic acid in the bath to prevent burning?

What thickness do you achieve and at I would assume reduced V from conventional Hard Anodising?

It's really di-electric properties and insulative property I am looking to improve upon.

CPS Ltd - Dublin, Ireland

October 30, 2019

A. Hi Bill. Decades ago I did some wastewater treatment work for a large manufacturer of electrolytic capacitors. You probably know this, but that industry used boric acid and tartaric acid ⇦ on eBay or Amazon [affil link] as their anodizing solutions.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

October 2019

![]() Thanks Ted.

Thanks Ted.

CPS Ltd - Dublin, Ireland

October 30, 2019

A. Hi Bill,

Anodized "ceramic-like" film may be thinner than traditional hard-anodized film (the thickness of the anodized film is ~30-50 mkm), however its di-electric properties are much better.

adv.

Bill, please contact me directly about possible testing.

Anna Berkovich

Russamer Lab - Pittsburgh, Pennsylvania

(ed. update July, 2025: sorry, Anna has retired)

November 1, 2019

Q, A, or Comment on THIS thread -or- Start a NEW Thread