-----

Etching to get roughened surface on Phillips screwdrivers

Q. When I was younger, phillips head screwdrivers had more "grip" to the end of them. This really helped when driving 4 inch screws into wood. They also had some horizontal ridges that bit into the screw to prevent it from lifting out. It seems today they just don't do that anymore.

I am wondering if there is any way to etch the end of my screwdrivers and bits for a rough finish? I am also looking into a D-I-Y EDM sinker for the ridges.

While I have looked into electrofinishing, it seems it is designed to polish, but maybe if I intentionally use wrong voltages I can get a rough surface instead :)

Entrepreneur - Lehi, Utah, USA

May 28, 2018

May 2018

![]() Hi Alan. Thanks for the question which inspired me to review the fascinating history of the Phillips head, and learn about one of its challengers, the Frearson (Reed & Prince).

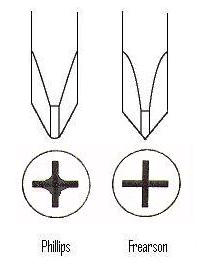

Hi Alan. Thanks for the question which inspired me to review the fascinating history of the Phillips head, and learn about one of its challengers, the Frearson (Reed & Prince).

The Phillips screwdriver was developed for early automation systems which lacked clutches or good torque limitation and thus tended to break off screw heads causing a serious line jam. So the Philips head was deliberately designed to 'cam out' instead of breaking the screw. Thus the problem you and I see with it was an important feature rather than a shortcoming :-)

Frearson screws have a cross head which looks nearly identical, but the cross has sharp corners instead of the slightly rounded corners of the Phillips. It is designed to stay tightly engaged rather than cam out like the Phillips. So those ridges and roughness you saw sound more likely to have been on Frearson screw drivers than on Phillips. I also read that the heads of long cabinet screws are Frearson rather than Phillips for this reason. You might check whether the screws in question have those rounded corners or straight corners and, if they're straight, look into getting Frearson screwdrivers instead of Phillips.

You can probably electroetch stainless steel screwdrivers, or simply etch them with ferric chloride ⇦ on eBay or Amazon [affil link] ; but plated screwdrivers would be ruined by attempts to etch them. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

June 22, 2018

![]() Thank you so much for your response, it led me in the perfect direction. It turns out what I was looking for was the Posidrive bits, but there are many variations these days. The one I was looking for was:

Thank you so much for your response, it led me in the perfect direction. It turns out what I was looking for was the Posidrive bits, but there are many variations these days. The one I was looking for was:

https://www.eBay .com/itm/10pcs-25mm-PZ2-Impact-Driver-Pozidriv-Magnetic-Screwdriver-Bits-1-4-Hex-Shank/202303053338?ssPageName=STRK%3AMEBIDX%3AIT&_trksid=p2057872.m2749.l2649

One of the interesting things I found was a diamond coated one:

http://www.acefixings.com/components/com_virtuemart/shop_image/product/5c0606f8cf6c096d4354df644da50b62.jpg

That got me thinking again about putting a surface finish on my tools, tweezers, Dremel

⇦ on

eBay or

Amazon [affil link] bits... I found a near endless supply of zirconia powder from dental labs, it needs to be sintered but that could be done easily and then electroplated on.

From my searches it looks like an electroless nickel plating may be the starting point to coat each crystal with nickel, then it can be added to the tools similarly to electroforming maybe. If you wanted to expose the sharp edges of the crystals, you might be able to do some electropolishing which would take the metal off the tips and place it back in the valleys, but shouldn't touch the zirconia crystals leaving them partially exposed and sharp.

It is taking me some time to make any progress with so many other projects, but thank you so much for helping me find what I was looking for - and a new hobby :)

- Lehi, Utah, USA

Q, A, or Comment on THIS thread -or- Start a NEW Thread