-----

Copper vs. stainless "Stress Tabs" for Electroless Nickel

Current question and answers:

Q. Hi Everyone! I am a chemical engineer working out of Central New York. I had a question pop up recently that neither myself or anyone else I ask can make heads or tails of.

"Why do we use copper stress tabs, instead of stainless, when testing EN plating baths?"

I didn't think it should matter, but I ran copper and stainless tabs alongside one another to test it out. It seems the stainless tabs always showed tensile, while the copper tabs would show tensile or compressive based on the bath's current [prevailing] conditions.

- Syracuse New York

January 15, 2021

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. I am looking to purchase Hull Cell ⇦ huh? Stress Tabs. These were previously purchased through Larry King (Rosedale, NY) but they are out of business. Does anyone have other contacts to purchase these Hull Cell Stress Tabs through?

H McCarthy- Massachusetts, USA

April 19, 2017

A. Hi H McCarthy,

There's hull cell stress tabs mentioned in Relli Technology webpage. You may check it out.

https://catalog.ilsmart.com/7407/js_24_1440_900/results.asp?s.Description=hull+cell+stresstab ⇩

Regards,

David

David Shiu

- Singapore

Ed. update May 2025: That link is broken and ilsmart.com is now a subscription-only site.

How do "Stress Tabs" work?

Q. I am doing some testing with a Hull Cell and would like to see if the stress tabs on the Hull Cell panels will work. Can someone explain more details about how this works?

David KraeuterSunnen Products Company - SAINT LOUIS, Missouri

June 8, 2018

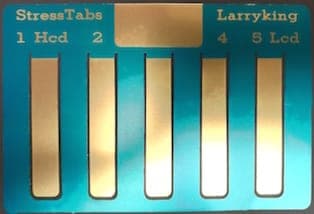

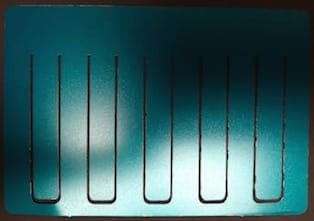

A. Hi David. Stress tabs are thin Hull Cell panels which are serrated in the style of a hair comb (but far fewer teeth), and coated with a maskant on one side so they only get plated on one side. The principle is that tensile stress in the plating on that side will cause the teeth to curl in, and compressive stress will cause the teeth to curl out, so that you can (perhaps among other things) determine what current density generates the least stress. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

June 2018

Q. How large are the combs? Is there an effect of having created extra edges that will influence the results of the Hull Cell test? Will the curling in or out of the teeth influence the current density it is experiencing?

David Kraeuter [returning]Sunnen Products Company - St. Louis, Missouri

June 8, 2018

A. Hi. The only one I've personally seen from was Larry King (as mentioned above). An old ad said they had 5 tabs, but I've seen articles where people have fabricated thin metal films on silicon for somewhat similar investigations.

I hear the test being called qualitative rather than quantitative, so the effects of plating on the edges of the foil, or the increased or decreased current as the tabs bend closer to or further from the another are probably not carefully documented things.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. I purchased a Hull Cell StressTabs and would really appreciate some guidance on how to use it. Here is what I know about it.

1) Material -- Copper alloy (65% Cu and 35% Zn)

2) Thickness of the metal is roughly 0.006"

3) All but a few areas are covered in a plastic coating

Should I adjust my current settings as compared to a standard hull cell since most of it is plastic coated?

Sunnen Products Company - SAINT LOUIS, Missouri

August 14, 2018

A. Hi David. I haven't personally used them, but the side completely covered in masking goes to the back of the cell. The unmasked area near the top would seem to be for the alligator clip connection. I don't know if there is a suggested reduction in current to apply based on the masked portion because I've never seen the instructions either. But the exposed area looks like about 40% of the whole area.

There are cardboard or plastic "Hull Cell Rulers" which give you the current density at any position along the Hull Cell depending on whether you set your rectifier to 1, 2, 3 or 5 amps. There probably should be, and maybe there is, a "Stress Tabs Ruler" that would be used in the same fashion, incorporating that 40% or so relative area factor; but if you can't find one, you can probably proportion from a standard Hull Cell Ruler.

What the StressTabs do for you beyond what a standard Hull Cell does is they bend according to the stress in the plated deposit. One common application is when trying to do a deposit at zero stress by maintaining the current density at the best level as indicated by least bending of the tab.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q, A, or Comment on THIS thread -or- Start a NEW Thread