-----

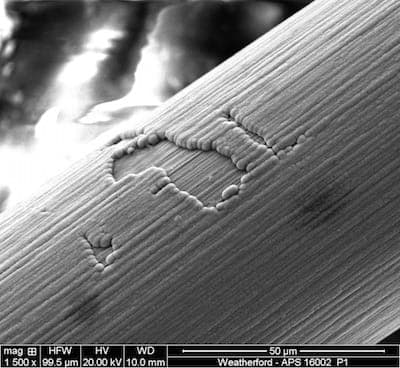

Micro Holes in Nickel Plating on Tungsten Rhenium Wire

Q. We plate 0.003" tungsten rhenium wires with nickel. We use a nickel sulfamate bath to electrolytically add plating. We have always had a problem with 0.001" diameter micro holes in the plating. Please see the attached SEM image. We have changed our strike and plating baths without any affect. We have an extensive cleaning process which entails DI water, MEK substitute, acetone ⇦ on eBay or Amazon [affil link] Flammable! , ethanol and a sodium hydroxide electrolytic etch. The spots are first seen after the strike bath and remain after plating. Is there any reason that tungsten rhenium wire would cause these types of issues to appear? Any insight as to the source of the micro holes would be appreciated.

Cameron KivelaEngineer - Boulder, Colorado, USA

October 6, 2016

A. Hi Cameron

Tungsten is difficult to plate on and adding rhenium to the alloy takes it outside my comfort zone but I can make a couple of comments.

Your cleaning process is way too complicated and may actually add to the problem. Unless your wire is greasy, the organic solvents do nothing. Acetone is a very popular and a particularly bad cleaner for plating because it evaporates so fast that it re-deposits any grease it may have dissolved and it is highly flammable. MEK (what substitute?) is nearly as bad.

DI water is the last in any cleaning line before plating.

Never use HF anywhere unless trained!

If you do, you MUST have the antidote gel on hand for instant use!

Calcium Gluconate

for HF acid burns

on eBay or Amazon

(affil link)

I see where you are coming from with the sodium hydroxide (cathodic?) etch but the more usual pre-etch for tungsten would be hydrofluoric acid 5-50% room temp 1-2 min. But don't even think of using HF unless you have the appropriate first aid measures (calcium gluconate gel) immediately available and know how to use it. You may be able to substitute ammonium bifluoride but the whole job is one for an experienced chemist.

You give no details of your strike bath (woods nickel would be a good start) or whether you are plating short lengths on a jig or continuous reel to reel, current densities etc., they are all important.

And as I said, adding rhenium to the alloy adds complications.

Geoff Smith

Hampshire, England

Q. Thank you Geoff.

HF would be outside our comfort zone for regular use but I will look into the ammonium biflouride as a cleaning agent. We currently use the alcohol as a last step due to the DI water causing some parts to stick together when dry. We are using Barret strike and plating solutions. We plate short pieces suspended in a jig. We use 0.207 A/in^2 for our current density. I have noticed that we can minimize the number of micro holes by using new DI for each rinse as we as a long low amp sodium hydroxide etch. We received EDS results which showed oxygen and carbon concentrations in the micro holes. Could this be skin cells? The ratio was 2.66 oxygen atoms to carbon atoms.

Advanced Probing Systems - Boulder, Colorado, USA

October 11, 2016

-- (apologies, not actually posted until 11/15/16 -- Ted)

Q, A, or Comment on THIS thread -or- Start a NEW Thread