-----

Dimension change after heat treatment of flat spring using alloy 25 0.2 Be-Cu Strip of NGK JAPAN

September 30, 2013

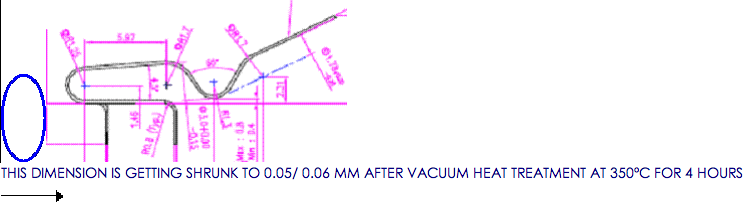

Q. WE ARE USING O.2 MM THICK Be-Cu ALLOY 25 FOR MAKING CONTACT SPRING. IN THIS SPRING CONTACT GAP OF 0.4 - 0.8 MM IS GETTING SHRUNK TO 0.05/ 0.06 MM AFTER VACUUM HEAT TREATMENT AT 350 °C FOR 4 HOURS. CAN YOU ADVISE HOW WE CAN RESOLVE THIS? WE ARE SOURCING Be-Cu STRIP FROM NGK JAPAN

QUALITY ASSURANCE - Bangalore, India

Q, A, or Comment on THIS thread -or- Start a NEW Thread