-----

Ultrasonic Cleaning with Micro 90 ruined Electroless Nickel, Turned Stainless Yellow or Black

Electroless nickel plating solution is "spring-loaded" and does not require electricity. Rather, the solution contains dissolved nickel plus reducing agents which cause the nickel to plate out on iron or nickel surfaces. Electropolishing is sort of a reverse electroplating which dissolves metal from the surface. Please search the site for more info.

Ultrasonic cleaning uses transducers that vibrate the solution in a way that creates 'cavitation', i.e., little pockets of vacuum. This reduced pressure allows the water in solution to vaporize, forming tiny bubbles of vapor sort of like 'cold steam'. These scrubbing bubbles provide a mechanical cleaning action.

In the cases at hand, however, the cleaning appears to be damaging the parts.

Q. Hello,

I have purchased several Nickel plated Stainless Steel bolts, and needed to clean them fairly well as my experiment requires very high cleanliness specifications. I immersed these bolts into a detergent solution (Micro 90 detergent, ~1.5%) heated to about 100 ° F in an ultrasonic cleaner. I checked back on them after about an hour and they had a black coating on them.

I took a few and tried a different detergent (Liquinox, 2% heated to 130 F in ultrasonic bath), and they turned even blacker. This coating seems to come off if I use a stainless steel welding brush, is this coating likely to be Nickel Nitride or Nickel Oxide, and do you have any suggestions on how to remove it chemically without removing the Nickel plating underneath?

As a follow-up, I purchased a bottle of Citranox cleaner, and have used a heated (60 C) 2% solution in an ultrasonic bath for several hours with minimal results.

Steve HardyVirginia Tech Physics Dept - Blacksburg, Virginia

2007

Multiple threads merged: please forgive chronology errors and repetition 🙂

The SST [stainless steel] bar received electro polish and then after ultrasonically cleaned using MICRO-90 cleaning agent concentrated with processed water and air dried. After this process a yellowish color like blemishes appears on the surface.

What do you think could be the cause of this discoloration?

Thanks

engineer - Irvine, California

July 23, 2009

A. Only the people that make Micro-90 know what is in it. They should be able to help you with the problem. If not, switch to another vendor. Most companies get serious if they think that you might switch to another product.

James Watts- Navarre, Florida

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. Our customer specified a new cleaning detergent (Micro-90) to use in our ultrasonic cleaner. We kept the solution at our standard temperature of 150 °F and ran the part for 15 minutes. The part is electroless nickel plated.

After running it in the ultrasonic cleaner it looked like this:

What do you think might be causing this staining? It can't be removed with IPA [isopropyl alcohol / rubbing alcohol] or Steel Ink Remover.

Dave Sheff- Amherst, New York, USA

May 21, 2013

Q. I'm actually looking for any similar issues; I heard Micro-90 should not be used on steel parts -- plastic only to prevent discoloration. I am hearing conflicting statements though.

What is your percentage of Micro-90 to water? I hear it is supposed to be 2% or lower to prevent discoloration.

What is yours?

Precision Swiss Products - Milpitas, California, USA

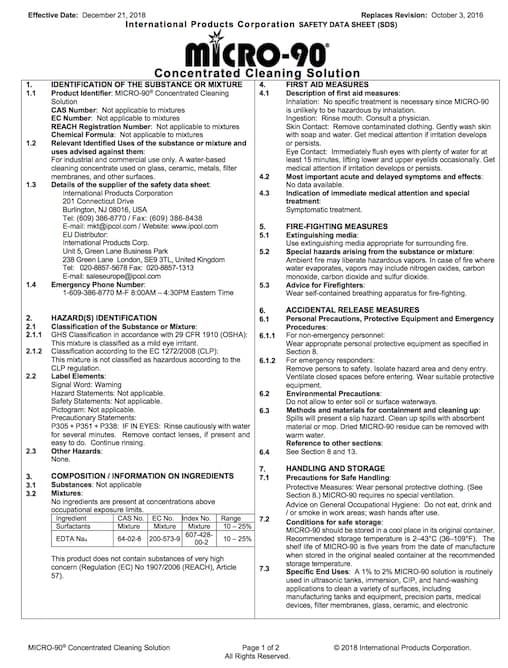

![]() Hi Michael. I don't know if Dave will reply since his posting was from 5-1/2 years ago. More participation from readers might arise if we make it a bit more generic rather than being about one specific trade secret formulation ... it seems to be EDTA and surfactants, and the SDS (safety data sheet) does say it etches nickel. Good luck.

Hi Michael. I don't know if Dave will reply since his posting was from 5-1/2 years ago. More participation from readers might arise if we make it a bit more generic rather than being about one specific trade secret formulation ... it seems to be EDTA and surfactants, and the SDS (safety data sheet) does say it etches nickel. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q, A, or Comment on THIS thread -or- Start a NEW Thread