-----

Marble effect on anodised coating

February 18, 2013

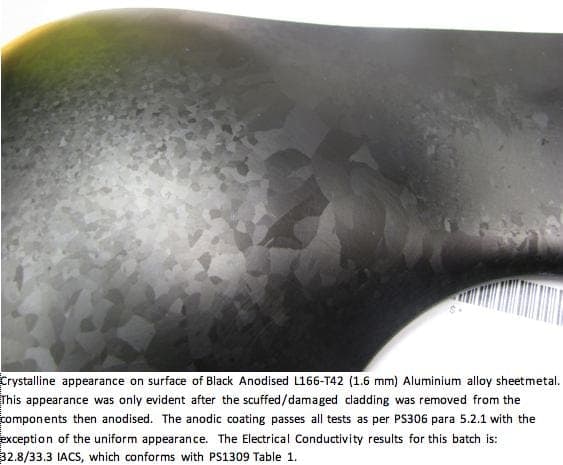

Q. Please see email image of problem.

The cladding on the parts had been locally dressed to remove forming/tooling marks, this causes us problems at the anodising process where it leaves a distinctive 2 tone appearance which is not acceptable to our customer. As a result of this we chemically removed the cladding from several of the components under controlled conditions in line with our customers requirements and re-anodised the parts leaving the finish you see.

Process Engineer - Northern Ireland

|

A. I refer to this as mottling. Very common on stripped parts. This alloy does not appear to be very homogenous. Did you refinish them (buff/sand/tumble) prior to re-anodizing? That should solve this issue, as long as you don't over etch during the 2nd pretreatment.  Marc Green anodizer - Boise, Idaho February 19, 2013 February 20, 2013 A. Hi Nigel, Aerospace - Yeovil, Somerset, UK |

February 21, 2013

Q. Marc/Brian,

Thanks for your feed back on my question. Unable to buff/sand due to specification requirements. Unfortunately we do not have a tumbler big enough.We did in fact believe it could have been grain shortening as the surface work hardened during the forming process. The material had been annealed directly before the forming process.Just a point that the marble effect was noticeable but not as much prior to removal of the cladding by etching.

- Northern Ireland

A. This effect could also be caused by zinc contamination in your etch tank. I have experienced this first hand when I started a new job and the first thing that was done was to put a air sparge in the etch tank for temperature control. Steel pipe was specified and the maintenance department decided that galvanized steel pipe was ok to use. The zinc was immediately stripped off the pipe and contaminated the bath, which by the way was 11,000 gals. Production was shut down until the bath could be treated to remove the zinc.

Tim Hamlett, CEF

- West Palm Beach, Florida, USA

March 6, 2013

Q, A, or Comment on THIS thread -or- Start a NEW Thread