-----

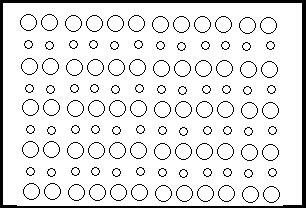

Electroplating different size features through resist

January 7, 2013

Q. Hello all,

I have a question regarding electroplating different size features through resist. I work for a semiconductor company and we plate Cu through resist. I am wondering what happens to the current density if I have features of different size on the die. Let's say I have 30µ openings and 60µ openings adjacent to each other, which ones plate faster, I mean taller? More generic question is how can we predict which feature plates taller or shorter if they are on the same die on the wafer?

Please provide on any insight you have on this.

Your input is greatly appreciated.

Thanks!

- US

A. Hi Satish. If you were not speaking of microelectronics, the answer would be trivial: plating is an electrochemical process where 96,485 coulombs (ampere-seconds) deposits 1 gram equivalent weight; so if the current density is the same, the deposition rate is the same.

However, in microelectronics the question is much more difficult because you deliberately use organic leveling agents with very large molecules that will shield any large areas from plating. These leveling agent molecules are so big that they will not fit into, and thus do not shield, small depressions. Sorry, I don't know whether these agents tend to shield 60µ openings more than they shield 30µ openings.

I hope that the supplier of your copper plating solution can offer some sort of graph, table, or chart that will give you some indications.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

January 7, 2013

Q, A, or Comment on THIS thread -or- Start a NEW Thread