-----

Nickel plating bi-metal screws

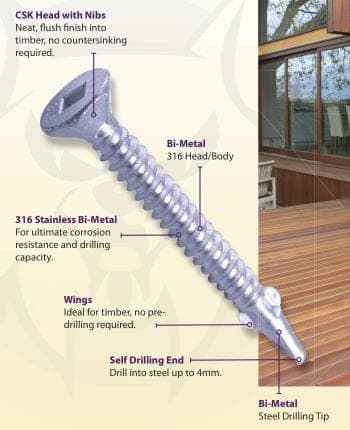

Q. We are selling some decking screws which are bi metal (316 head with a carbon steel drill tip for better drilling capacity).

After the welding process, the manufacturer insists on coating the screws, making them look just like standard screws. Customers are not impressed at paying a premium for stainless then getting a screw which looks ordinary. Our thinking is to ask the supplier to nickel plate them, but what will happen to the nickel plating in corrosive environments?

|

Reuben Stewart fastener wholesale - Bendigo, Vic, Australia July 18, 2012 A. Hi Reuben. An impressive fastener! The nickel plating may not be capable of protecting the carbon steel drilling tip from corrosion over the long run, particularly in pressure treated wood, but that doesn't seem important as that will be well imbedded into the wood, and the tip does not provide any of the retaining power of the screw. But there might be some concern about rust stains from the underlying steel if employed on ceilings rather than floors. I would investigate the possibility of copper plating or nickel plating or titanium nitride PVD coating just the tips as you are trying to emphasize the two different materials of construction and their junction point. Don't quote me on this, try it instead, but maybe just a simple immersion into copper sulphate ⇦ on eBay or Amazon [affil link] will turn the tip copper colored while not depositing on the stainless steel. Regards,  Ted Mooney, P.E. Striving to live Aloha finishing.com - Pine Beach, New Jersey Ted is available for instant help or longer-term assistance. July 18, 2012 |

Q, A, or Comment on THIS thread -or- Start a NEW Thread