-----

Nickel surface treatment solution wanted

February 24, 2012

Q. Hi

I have a problem where nickel plating surface is not so good. As I think, the nickel process works well with Reel to Reel type plating.

I found nickel plating surface failure in the middle of working, there is no [known] changed working condition..suddenly happened.

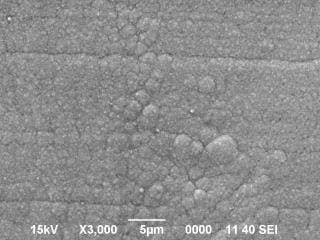

Nickel plating surface got so many rounded projections (shown in photo / SEM x 3000).

I don't know how to deal with it. I am waiting for your help!

-working condition-

1. Reel to Reel type / velocity : 4m/min / phosphor bronze

2. Nickel 600 g/l, boric acid 40g/l, Nickel Chloride 6 g/l

3. Solution temp. 55~60 degree

4. Current density 29(A) / voltage 5.5(V)

- Ansan city, Kyounkido, South Korea

Just to clarify: your nickel concentration is 600 g/L? Is that even possible?

- Brisbane, Queensland, Australia

February 27, 2012

February 28, 2012

I checked the concentration of nickel.

600g/L is right..

Nickel bath volume is 300 Liter. Net nickel solution volume is 250 Liter.

- Ansan city, Kyounkido, South Korea

February , 2012

Hello, Hyo.

You undoubtedly mean 600 g/l of nickel sufamate, Ni(NH2SO3)2 or Ni(NH2SO3)2.4H20, not nickel. 600 g/l nickel would indeed be impossible.

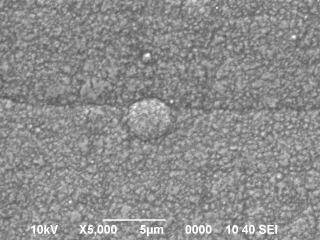

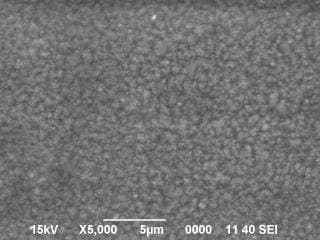

This looks like the beginning of nodule growth, which in turn sounds like brightener/addition agent problems, although we probably can't rule out a mechanical failure of a solution jet or something like that. Can you do a Hull Cell ⇦ huh? test or a stress tabs test to see if anything can be learned about what happens at other current densities?

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q, A, or Comment on THIS thread -or- Start a NEW Thread