-----

Wetting agent, Leveler, Brightener, and Stress Reducer for Nickel Cobalt Plating

August 9, 2011

Q. Hi All,

I am a student researcher and a beginner in electroplating. I am trying to electroplate Nickel Cobalt alloy on a Silicon Wafer. I have done research on this, but I could not find what kind of chemicals I should use for wet agent, leveler, brightener, and stress reducers for NiCo plating.

Here are two electroplate baths I am planning to use:

Bath1:

Nickel Sulfamate

Boric Acid

Nickel Bromide

Cobalt sulphate

Bath2:

Nickel Sulfamate

Cobalt Sulfamate

Nickel Chloride

Boric Acid

Thanks

Thura

Student - Berkeley, California, USA

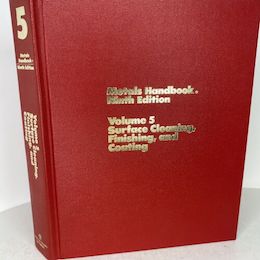

9th Edition, Vol. 5

"Surface Cleaning, Finishing & Coating"

on eBay or Amazon

or AbeBooks

(affil link)

A. Hi, Thura. As a "beginner in electroplating", we need to let you know that end users almost never attempt to develop their own addition agents. Rather, people almost universally purchase proprietary plating bath chemistry that comes complete with all of these addition agents.

But if your intention is to try to use generic chemicals in place of modern proprietary addition agents, Volume 5 of the 9th Edition of the ASM Metals Handbook, "Surface Cleaning, Finishing and Coating" .

has an excellent chapter on nickel plating which explains those generic addition agents in some detail. The newer edition of Volume 5, "Surface Engineering" has been stripped of a lot of that information. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

August 10, 2011

A. If I were going to experiment with this, I would only use your second bath as the anion of the Ni and the Co is the same. Makes life simpler because you can use sulfamic acid to lower the pH as it rises.

Nickel and cobalt plate very much alike. The cobalt is harder and brighter and whiter than nickel.

Find a couple of good books on alloy plating before you start.

A slight difference in pH or temperature or agitation or current density or anode area of each can make a large difference in the percent of each alloy.

I think that you will find it a bit easier than most alloys to plate with reasonable repeatability.

Do not be shocked if the edges are a slightly different alloy than the center of a test panel.

- Navarre, Florida

August 10, 2011

Q, A, or Comment on THIS thread -or- Start a NEW Thread