Home of the world famous 'finishing.com HOTLINE' since 1989

-----

Passivation of stainless steel: Analysis & replenishment of nitric acid, chromate, iron

Q. I am looking for the source (book, ASTM spec, etc.) of the nitric acid replenishment equation posted by Ira_Donovan. I would like to understand how the replenishment equation was derived since it does not appear to follow a normal dilution equation. Thank you in advance for your help.

Jill Miller- Williamsport, Pennsylvania

April 13, 2022

A. Hi Jill,

Looking for the source book sounds like you might be trying to find a "not found on the internet" derivation, as auditors seem to require, no matter how trustworthy the source? It's definitely a dated requirement, and I seriously wish they'd just publish the details in an ASTM spec, so we can all use it!

I can give the titration for both nitric & dichromate from memory ... but the calculations? Ehh ... I can give a NADCAP accepted full correction once I'm back at my desk.

There is a source online that is related to an approved software supplier:

www.anoplex.com/Titration_Passivate_T2.html

It's not quite what I use (even though I use that software... I heavily modified mine in the nuts n bolts ), or had approved. But if you need to prove a source, it's an option. In conversations with auditors, they accept vendors and consultants as approved sources.

In a pinch, I've actually run enough tests to develop an internal titration technique and calibration curve, shot the whole thing off to my chemical supplier for formal verification, and filed the approval letter away for posterity. You can do this, it is totally legit. The process is a pain in the toosh, but no one can argue with a documented repeatable self-derived titration. Scientific method and all that...

Opinion here: it's a bit funny that auditors will accept a whole mess of internal lab technique of dubious documented origin -- as long as it's documented, and they approve of it over internet community confirmed SOPs. I guess any of us with a decent set of glassware and a .001 scale can develop our own methods, if we document them properly. And I don't disagree with this at all!

One thing that has caught folks (myself included) up is that it's not a straight g/L for dichromate in nitric. The spec asks for g/kg.

What process specification are you adhering to? I'll keep an eye on this thread and if I can get you a good equation and a corroborating source, I'll be back. Even if only to drop an excel doc with some self-calibration prompts ;)

Rachel Mackintosh

Lab Rat / WWTF - Greenfield MA

Q. Rachel, we passivate and titrate using basically the same formulation that you state in your post. My question to you or anyone willing to respond: "is deionized water required?" Can you do this test w/distilled water?

Thanks,

Doug

Special Processes - DoD - NICKTOWN, Pennsylvania

June 24, 2022

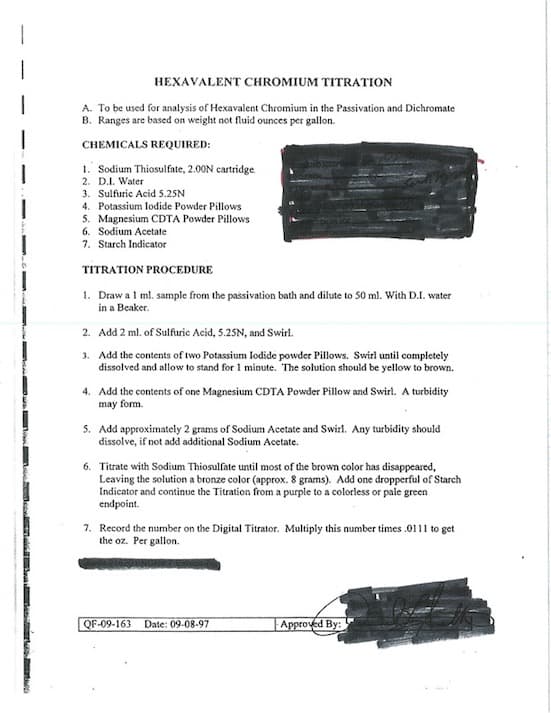

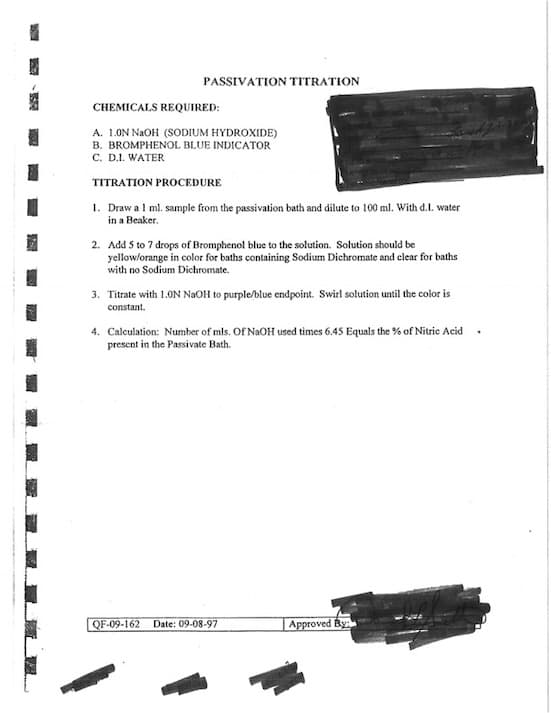

Q. Trying to locate the origin of these two procedures: QF-09-162 & QF-09-163. A recent audit requires the procedures used to have an origin (ASTM, ASME, POT, LSD) etc. Been using these since 2005 as is. Would anyone be able to lead me to the origin of these documents? Any help will be appreciated.

D Walker- Grand Rapids Michigan

January 31, 2024

A. Hi D,

Those numbers don't sound familiar to me, but we appended your question to this thread because you may find that the procedures you follow are the same as something quoted here, such as the Anoplex procedure linked to by Rachel.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Good day. Anoplex shows a Boeing BAC5625. When I search Boeing, that procedure number does not exist. I don't believe an acceptable answer of the origin of a procedure was "from the internet" will work. At a loss here. Not a chemist by any means, just a near retired NDT Level III.

Can anyone recognize the attached, and provide some insight? Thanks.

Been doing the same thing since 2005, never any issues. Now requirements are contradicting in certain checklist, as well as requiring the origin of our procedures adopted back in 1997. Very frustrating at the least. So much inconsistency in interpretation between auditors and final review folks. Part drying is a thermal treatment, then it's not, then it is, then it's not. Trying to locate the origin of QF-09-162 & 163, published by some chemical company in 1997. It's like trying to locate the driver license of my driving instructor's mother...

If anyone can lead me to a recognized lab, standard society, that would have released these procedures when Moby Dick was a minnow, it would be fantastic. ASTM or someone needs to publish a standard practice for titration of nitric acid and sodium dichromate (QQ-P-35, AMS-2700 type 2) passivation baths that is accepted by NADCAP. Excerpts off the www and internal procedures are not accepted anymore, regardless of their accuracy.

Thank you.

- Grand Rapids Michigan

A. D,

Titration math is on the level of first-year chemistry. It's a sad day when an organization such as NADCAP will not allow a processor to possess a procedure unless it has the official stamp of approval of somebody or other.

Frankly, I don't think the actual problem is that your titration procedure isn't from ASTM or AMS or what have you. The actual problem is that all the math is hidden. The procedure provides a constant with no source or justification. It's fine for the guy on the shop floor to just know that the 6.45 in the nitric acid titration is a magic black box that gives the correct answer, but an auditor probably just wants to know that 6.45 wasn't picked randomly from a hat. It ought not need an ASTM committee to ensure the number is correct, it just needs to show the calculation written out completely. That way it hopefully justifies itself and you wouldn't need a source to point fingers at as being responsible for things.

I.e., for the nitric acid titration, something that goes from the mL of NaOH solution, to moles of NaOH, then to moles of acid based on the equivalence point relevant to the bromophenol blue

⇦ on

eBay or

Amazon [affil link]

indicator being used, and then to volume percent based on known properties of the nitric acid stock solution. All that math put together will be that 6.45.

As a side note, based on the informal nature of the documents, with no SDO or company name listed, and especially the handwritten signature next to "approved by", I think this is most likely an internal procedure developed at your own company, probably by somebody long retired who was presumably a chemist, or else copied it from some other trusted source. Yes, it would have been nice had it been clearly identified as such, with the original author's name noted as well.

Ray Kremer

Stellar Solutions, Inc.

McHenry, Illinois

A. "Powder Pillows" is a term used by Hach to describe some of their products.

A search result of 'Magnesium CDTA Powder Pillows' will lead you to a page describing the product. Halfway down the page is a drop-down list titled 'Methods/Procedures'. From that list, Method 8211 appears and may be the origin of QF-09-163. QF-09-163 appears to use some of the 'Optional reagents' to address interference. Very similar wording. Other differences exist.

Of interest, Method 8211 appears in Hach's Water Analysis Handbook. The Scope & Application for the test method is for 'closed system cooling towers', with a range of 20 - >400 mg/l. The typical sodium dichromate concentration range for a passivation solution is 20,000 - 30,000 mg/l (2 - 3% w/w).

Search 'Passivate T2 Titration' and you should find the Anoplex procedure mentioned in the thread. At the bottom of the procedure, reference is made to Boeing, Document D180-17994-1, procedure # B-156. If you do work for Boeing, maybe you can get a copy. I would hope the document would also have a procedure for nitric acid titration.

If you can't get a copy from Boeing, consider looking at Section 3.5.5 of MIL-M-3171, superseded by AMS M3171 (2018). While the process is pickling of magnesium with nitric acid and sodium dichromate, solution control should be the same. QF-09-162 produces the same result.

- Green Mountain Falls, Colorado

Ed. note: Excellent research Willie. Thanks!

⇩ Related postings, oldest first ⇩

Q. HOW TO ANALYZE THE BATH CONTENT IN NITRIC ACID AND SODIUM CHROMATE SOLUTION? WE ARE USING NITRIC ACID 21-24% AND SODIUM CHROMATE 2.5% -3.0%. CAN ANYONE HELP OUT IF YOU HAVE THE TEST PROCEDURE FOR THE SAME?

PAPPU GPLATING SHOP EMPLOYEE - INDIA

May 10, 2011

A. 1 Ml soln 250 ml flask, add 100 ml D.I. water, 30 ml 50% phosphoric acid,10 ml conc. hydrochloric acid. Add 1.0 g potassium iodide ⇦ on

eBay or

Amazon [affil link]

, titrate with 0.1N sodium thiosulphate

⇦ on

eBay

or

Amazon [affil link]

to straw colour, add 1ml starch indicator, continue titration colour change from dark blue to colourless, giving titre A.

Sodium dichromate oz/gal= 0.662 X A

Nitric acid= 1 ml sol'n 250 ml beaker [beakers on

eBay

or

Amazon [affil link] , add 50 mls D.I. water, titrate with 1.0 N sodium hydroxide to ph 3.57(calibrate meter ph range 1-4) giving titre B.Nitric acid in %B.V.=6.45 X B. This works for me, Any new analysis procedure it's a good idea to make known standards to verify results. Good luck.

- Toronto, Ontario, Canada

A. Pappu,

Do you mean sodium dichromate? It looks like a passivation formulation to me. The analysis method won't be any different, just the calculation will change.

Nitric acid can be done by a simple acid-base titration using an appropriate indicator; bromocresol green

⇦ on

eBay &

Amazon [affil link]

would work well I think.

The chrome can be done by an appropriate REDOX titration. Use ferrous ammonium sulphate with sodium diphenylamine sulphonate indicator, back titrate with potassium dichromate.

A couple of good reference books with lots of analysis techniques common to treatments are The Electroplater's Engineering Handbook .

and Arthur Vogel's Textbook of Quantitative and Semi-quantitative Analysis ⇨

Aerospace - Yeovil, Somerset, UK

A. See thread 15860

Willie Alexander- Colorado Springs, Colorado

Ed. note: Based on Willie's good suggestion, we've merged thread 15860 directly into this one. Please forgive the consequent lack of chronology:

|

f o r m e r l y T h r e a d 1 5 8 6 0 f o r m e r l y T h r e a d 1 5 8 6 0 f o r m e r l y T h r e a d 1 5 8 6 0 |

(formerly 'Thread 15860') Q. Help! Need formulas for replenishment of passivation tanks. I already have the formulas for replenishment if acid level and dichromate is low but not if the acid and dichromate level is high? I can't seem to transpose the formulas the opposite direction. Can anybody help me out? Thanks, Jason Katorski- Camarillo, California, USA 2002 A. There's a problem here: acid and dichromate should always decrease with use. How did the bath get too high? Are the analyses being performed properly - verify your numbers before you do anything. I say this because to fix the immediate problem, you'll have to decant part the bath - do the math to figure out how much to decant - and add back purified water. You may also need to add back one of the two components if they weren't out of spec to the same degree.  Megan Pellenz - Syracuse, New York A. Here are the two analyses with calculations for a Type II, QQ-P-35C (canceled) [link is to free spec at Defense Logistics Agency, dla.mil], passivation solution. SCOPE: To determine the concentration of Sodium Dichromate in a solution. EQUIPMENT: 2 mL Pipet PROCEDURE: CALCULATION: REPLENISHMENT: W1 = P*V2 P = Density of the solution. DILUTION: W1 = P*V2 P = Density of the solution. and, SCOPE: To determine the concentration of Nitric Acid in a solution. EQUIPMENT: 5 mL Pipet PROCEDURE: CALCULATION: C1= V1*F1*N1 REPLENISHMENT: W1= [(C2-C1)*V2] / 100 DILUTION: V3 = [(C1-C2)*V2] / C1 I assume the formatting will be correct as I cut and pasted the required information. Best of Luck, Ira Donovan, M.S.F.Kansas City, Missouri 2002 Q. I incorrectly stated the information. Our tanks lose water from evaporation. When we titrate it shows a higher than spec acid and chromate level. We've been adding water then titrating until we get the levels per spec. Just looking to find how to calculate the correct amount of water to add to our tanks. It would save us a lot of time and guessing. Will try the formulas you attached. Thanks I have the same formulas from my customers specs for replenishment as stated by Mr. Donovan. Problem is they specify only using 50ml of water not 100ml. I tried both procedures for titration and yielded different answers. Which do I follow? Thanks, Jason Katorski [returning]- Camarillo, California 2002 A. The correct sample size for the Sodium Dichromate titration procedure should be 2 ml and not 5 ml. Willie Alexander- Colorado Springs, Colorado |

Q. Hello all,

Looking for a titration procedure for Nitric acid in a Sodium Dichromate bath

employee - Fullerton, California

May 24, 2011

? Hi, Esppi.

Please see the above answers. If they are not the answer you need, can you please rephrase your question in terms of the answers already offered? Thanks!

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

(you are on the 1st page of the thread) Next page >

No dead threads!

Your Q, A, or Comment puts this thread on The Finishing.com HOTLINE.