-----

Dullness problem on nickel plating

encountered dullness of nickel plating at high current density areas , e.g., around the center hole of a flat surface but the surface has bright nickel appearance. since we are keen on aesthetics, we cannot run with this condition.

Earlier we did dummy plating on the bath to remove metallic contamination such as Zinc and copper. Now, had stabilized process parameters such as boric acid, nickel content, nickel chloride, pH, temperature. Also did addition of additives and brightener as per TDS but we are still experiencing the same dilemma.

please advise on what else to check. thanks.

process engineer - Philippines

February 28, 2011

Is around the center hole a high current density area? maybe a photo will help.

Daniel Hernandez- Bucaramanga Santander Colombia

March 2, 2011

First of all, I'm assuming we are talking about nickel sulfamate plating.

1. Is it possible you have iron contamination? If so, raising the pH above 5.5 and treating with hydrogen peroxide will cause the iron to precipitate out.

2. Is this a rinsing issue? If the pretreatment is not getting rinsed thoroughly, is it possible that it is bleeding out in solution?

3. Exactly what current density are you plating at?

- North Tonawanda, New York

First of two simultaneous responses -- March 2, 2011

May be you will have to clearly mention the parameters you followed while dummying and the operating conditions.Dullness around the center hole - is it not Low current density area!

T.K. Mohan

plating process supplier - Mumbai, India

Second of two simultaneous responses -- March 2, 2011

Hi,

From the information given by you it seems the center hole is a high current density area and your problem may get reduced if you can divert some part of the current away from the center, by using appropriate auxiliary anodes. Also, reducing the current density may help serve your purpose.

All the best.

- Gujarat, India

First of two simultaneous responses -- March 3, 2011

Hi,

check the filtrations, add some carbon and keishelkar powder fine media powder for fine filtrations or if you have the cartridge filter then filter the solution with new cartridges, May be the organic impurities are creating problems for you.

Praveen Kumar

plating process supplier

Mumbai, India

Second of two simultaneous responses -- March 7, 2011

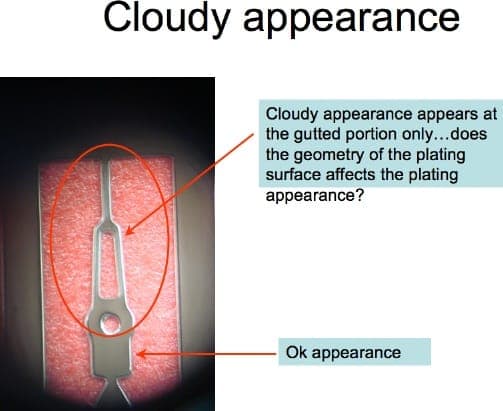

For illustration purposes, please see attached pictures of our materials being plated. I also include picture of cloudy sample. please comment..

- Philippines

March 7, 2011

Q, A, or Comment on THIS thread -or- Start a NEW Thread