Home of the world famous 'finishing.com HOTLINE' since 1989

-----

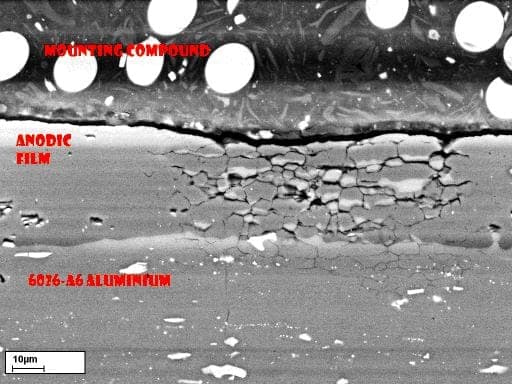

Hard Anodizing Defect: "granulation"

November 23, 2010

We are hard anodizing 6026-A6 aluminium for use on wind turbines in hostile environments; coastal, Gobi Desert, North Sea, etc.

We find that we are getting bright reflective flecks in the coating.

Microsectioning reveals that the anodic coat has "granulated" in local patches about 20 or 30μm diameter and that the base aluminium also shows a similar effect (see photo).

This is a concern as it represents a breach in the coating and a potential corrosion site.

Our anodizer says its not burning and that he has never encountered this before and blames the stock material.

Examination of stock material can find no artifacts of this nature until after anodizing.

Has anyone run across this sort of thing before? Did you get to the bottom of it?

Quality operative - London, United Kingdom

Is the surface "work hardened" and are you converting the whole work hardened area to aluminum oxide, which then flakes?

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

First of two simultaneous responses -- November 24, 2010

Being a mag-silicide alloy, I would expect the "bright flecks" are mostly magnesium. Have you performed an element analysis on the area? If not, I would think you should so so.

If it is indeed a magnesium issue, I'm not too sure if there's much you can do as a coater to resolve the issue, except stress that your customer try to find an Al supplier that has a more homogeneous product.

Marc Green

anodizer - Boise, Idaho

Second of two simultaneous responses -- November 25, 2010

Thanks for the prompt answers.

This is extruded bar and the directionality in the matrix inclusion distribution indicates a hot forming direction parallel to the horizontal plane of the cross-section. The granular structure in the matrix material looks fairly equiaxed which suggests an annealing or recrystallisation process. I looked through the bulk of the sections and could not see any granular areas other than those below the surface defects.

EDX analysis does not show any undue concentration of Mg but we have not looked at the flecks in isolation yet.

- London, United Kingdom

November 29, 2010

No dead threads!

Your Q, A, or Comment puts this thread on The Finishing.com HOTLINE.