-----

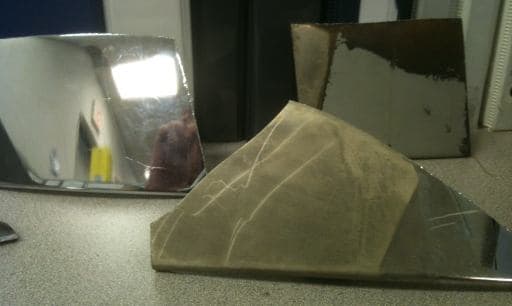

Appearance of "cracks" in chrome plated ABS plastic - post chrome

July 20, 2010

There has been a sporadic development of visual lines post chrome plating on a plastic ABS part. No evidence of the lines can be seen in the raw product, flaming & glacial acetic test have been completed on the raw part to see if stresses or the cracks are under the surface. The lines can look like knit lines; however, it is clear that a knit would not be in the areas that the lines are surfacing, also at times there are more than 1, 2 or sometimes 3 lines in one area.

Ever seen anything like this? What would be the root cause, or contributor?

Employee - Sterling Heights, Michigan, USA

July 28, 2010

Copper (in case you are using it) is rather ductile and generally low stressed, so, hardly could it contribute. Chrome, though brittle and highly stressed, is too thin to be the culprit. I'd bet it is your nickel that is out of balance and highly stressed.

Guillermo Marrufo-Monterrey, Mexico

Monterrey, NL, Mexico

August 2, 2010

Dear Jonathan,

As Guillermo Marrufo says, in a normal layer thickness ratio situation, it looks like it is the nickel. The root cause we can't tell, but to list a few possibilities:

1. Overdose of brightener(s).

2. Long term dosing of brighteners and a long time no activated carbon treatment of the Nickel electrolyte (needed to periodically remove breakdown products from the brighteners and other organic contaminations.)

3. pH too high

4. Boric acid too low.

5. Metallic contaminants (Zinc, Copper eventually others in your nickel electrolyte).

Some work to do...

Best regards,

Harry van der Zanden

consultant - Tilburg, Netherlands

Q, A, or Comment on THIS thread -or- Start a NEW Thread