-----

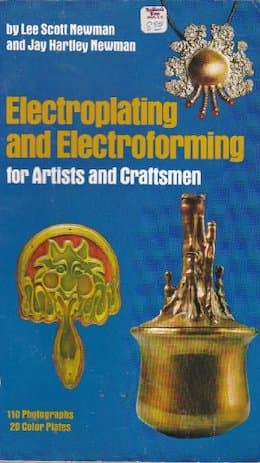

Electroforming (electroplating) onto Wax?

for Artisans, Jewelry, Crafts

avail from eBay, AbeBooks or Amazon

avail from Amazon

avail from Amazon

avail from eBay, AbeBooks or Amazon

avail from eBay, AbeBooks or Amazon

(as an Amazon Associate & eBay Partner, we earn from qualifying purchases)

Q. Hi all,

This is Rajesh from India. I am Hobbyist of wax art. Recently I read some article on hollow article prepared by using electroforming.

My idea is to create a wax art, paint it with electro-conductive material & electroform it using silver. I have searched a lot for electro-conductive paint for wax, but unable to locate any.

Please suggest me with the best option to do this (cheaper is preferred).

Thanks in advance.

Regards

Hobbyist - Pune, Maharashtra, India

May 27, 2010

A. Pranam Rajesh

Try graphite powder

⇦ on

eBay

or

Amazon [affil link] or bronze powder

⇦ on

Amazon [affil link] . You may prepare your own conductive paint -- simply mix bronze powder with very diluted nitro lacquer

⇦ on

eBay

or

Amazon [affil link] .

There are some very good infos on D-I-Y electroforming, some good and download free books on electroforming can be downloaded from internet archive website (even booklet by M.H.Jacoby -inventor of process/in german -- but try google translator, it is free. Hope it helps and good luck!

- Cerovski vrh Croatia

for Plating Shops & Engineers

Electroforming by Peter Spiro (1971)

avail from eBay or Amazon

Bureau of Standards: Electroforming of Waveguide Components

avail from AbeBooks or Amazon

Electroforming of copper for high vacuum applications

avail from AbeBooks

Fabrication of liquid-rocket thrust chambers by electroforming

avail from AbeBooks

A survey of electroforming for fabricating structures by W.H. Safranek

avail from AbeBooks

Electroforming in Restorative Dentistry

avail from AbeBooks or Amazon

Principles of electroplating and electroforming by William Blum (1949)

avail from eBay, AbeBooks or Amazon

(as an Amazon Associate & eBay Partner, we earn from qualifying purchases)

A. Hi Rajesh,

A lot of people are doing electroforming on wax. Silver conductive ink

⇦ on

eBay

or

Amazon [affil link] is the best option and is available. Try looking for it.

Regards

T.K. Mohan

plating process supplier - Mumbai, India

A. Silver Electroforming can be done on wax in a Silver Potassium Cyanide Electroplating bath with higher metal concentration.

If the wax piece is finished properly than the result will be good ... Use a fine copper powder

⇦ on

eBay

or

Amazon [affil link] mixed with NC thinner

⇦ on

eBay

or

Amazon [affil link] and NC lacquer

⇦ on

eBay

or

Amazon [affil link] and spray it on the wax, this will make the wax conductive ... rest of the electroplating process. If you want to make it hollow than you will have to deposit higher thickness, drain out the wax, and after that do the surface finishing. We are doing silver electroforming very effectively using the above process ....

- Bhavnagar, Gujarat, India

A. Brass powder or gold powder or graphite powder; 3 powder : 2 lacquer : 16 thiner

Silver electroforming: 1-silver p cyanide, 2-potassium cyanide, 3-potassium carbonate, 4-potassium hydroxide, 5-antimony potassium tartrate, 6-selenious acid.

Good luck.

Majed Janineh- Beith Lehem, Palestine

Is it necessary to remove wax from hollow electroformed jewelry?

Q. Please tell me if I have to empty my electroformed gold pendant of wax for sale and how can I do it?

Best regards,

- shiraz iran

February 3, 2017

A. It is not necessary to remove the wax, but doing so will make the electroformed product much lighter! You will, of course, use a low melting point wax and have designed the electroform to have an escape hole for it, so all you do is carefully heat the electroform to a suitable temperature and the wax will flow out. Alternatively, you can use a suitable solvent, but that will depend on the type of wax used.

Trevor Crichton

R&D practical scientist

Chesham, Bucks, UK

Q, A, or Comment on THIS thread -or- Start a NEW Thread