-----

How durable are brushed zinc countertops?

Q. Someone has suggested I use "brushed zinc" as a counter top in my kitchen. I'm trying to find out how durable brushed zinc is. Will it stain? Will it tolerate water? Must it be sealed? How often must it be re-sealed? If any zinc geniuses out there want to offer some advice, it would be appreciated. Thanks.

Andrew Gottlieb- Los Angeles, California

2000

A. Just a suggestion, Andrew. My company sells a product available in sheets that I would think could be used for a counter top application over a sub-base of plywood. It is copper, coated with an alloy of tin and zinc, intended for use as roofing, but is very weather resistant, and has a gray, metallic luster somewhat like zinc, but much more durable, and you should be able to maintain the appearance, far easier then unalloyed zinc would. It could be brushed to give the appearance you desire, before installation. (This is being suggested only because I would like to see you achieve the effect you want, I am an environmental technician, not in Revere sales. Good Luck.

W. Carl Ericksoncopper products. - Rome, New York

A. I think that I would stay away from having a brushed finish for a counter top - it would provide a breeding ground for bacteria in the recesses of the brush marks. Just a thought.

Dan Brewerchemical process supplier - Gurnee, Illinois

A. Andrew, I see my local PBS TV station just happens to have a show scheduled with a zinc sheet ⇦ on eBay or Amazon [affil link] counter top material used in a renovation project. I'll be checking that for info, and perhaps it will also be broadcast in Lalaland soon.

W. Carl Erickson [returning]copper products. - Rome, New York

A. Andrew, I was disappointed with the PBS show. The metallic counter top, shown only briefly, was stated to be a zinc material, from France, without any other details. Addressing Dan's comment, I completely agree that pure copper has been shown in testing to have the most effective antibacterial properties of any of the metals commonly used for countertops, including copper alloys like brass or nickel silver. This is for flat rolled sheet, unbrushed. Stainless steel, by comparison, has practically no antibacterial effect. I have seen copper used for the top surface of bars, and it was easy to keep attractive. There are tiles available, but most are copper plated, not solid copper, I think. Also the cracks between tiles could be a refuge for bacteria, I suppose.

W. Carl Erickson [returning]copper products. - Rome, New York

Q. I too, was recently told to use zinc as my kitchen counter top.

Does anyone have a manufacturer or retailer for this material?

Layne Lieber- Quogue, New York

2000

Ed. note: Names are okay, but no testimonials, folks! That encourages salespeople to post with fictitious names, posing as satisfied customers -- and then their competitors post long dreary prose of why theirs is better, and we end up having to delete the whole thread :-(

A. I just browsed for "zinc countertops" and came up with several companies who laminate zinc sheet ⇦ on eBay or Amazon [affil link] to various backings for countertops, backsplashes, etc.

James R. Molnar- Chicago, Illinois

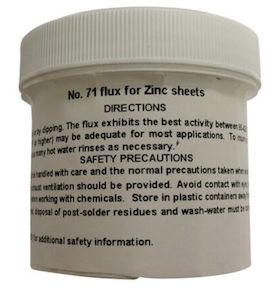

A. Zinc is indeed used for countertops, and some objections, while understandable, end up being overstated. Zinc has been widely used as a counter top for a very long time. If my recollection from a recent tour is correct, the food preparation counters at Cornelius Vanderbuilt's "Breakers", the grandest of the grand mansions of Newport, were all zinc.

However, do not use galvanized sheet (steel sheet dipped in zinc) because this is sometimes chromate conversion coated (dipped in hexavalent chromium), and it's steel not zinc.

Here are links that give you contrasting insights into the zinc counter top situation:

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Ed. note: Argh -- the futility and wasted effort of offsite links! Not one of the three works a few months later! But we managed to re-find two of them.

Ed. update: And now one of those two new ones is gone again. NEVER follow expired links -- hackers often buy them to be linked from trusted sites and then install malware.

Q. Hi - I have just purchased a great dining table with a Zinc top. My kids have stained the surface - and my wife tried to clean it with... vinegar ⇦in bulk on eBay or Amazon [affil link] - which has made it far worse!

Is there any tried and trusted way of cleaning a zinc surface?

Thanks in advance!

Bob GreenHomeowner - London, United Kingdom

2005

A. Caring for Your Zinc Countertops --

Zinc is a resilient, self-healing material, but for best results, please adhere to the following:

Cleaning

For normal cleaning, use a mild, non-acid based soap (Dove, Ivory, etc.) and rinse thoroughly with water. Promptly wipe up liquids to avoid discoloration or rings. Avoid harsh, abrasive cleaning products.

Avoid acids coming into contact with the countertop as it may remove or damage the hand crafted patina finish permanently.

Do not cut on Surface. Zinc is softer than stainless steel and, therefore, more susceptible to scratches when a sharp edge is directly applied to the surface. Use of cutting board is recommended.

Do Not Place Hot Items Directly on Surface. Zinc has a melting point of 300 °F (approximately 150 °C). To avoid permanent damage, use trivets or hotplates instead of allowing direct contact with hot surfaces.

Apply a non-toxic edible beeswax

⇦ on

eBay

or

Amazon [affil link]

finish onto your countertop surface once a year for extra protection. Try "Culinary Wax".

Expect Your Zinc Countertop to Be Unique

Zinc is a "living" material and over time will develop a distinctive patina based upon your pattern of use. A unique blue-grey hue will develop over time and areas of more frequent use and cleaning will remain lighter while areas that are used less often will be darker.

MetalTech-USA - Peachtree City, Georgia, USA

November 3, 2014

A. Zinc's melting temperature is 419.5 °C.

Orlando Wiebe- Winnipeg Manitoba Canada

September 7, 2015

Q, A, or Comment on THIS thread -or- Start a NEW Thread