-----

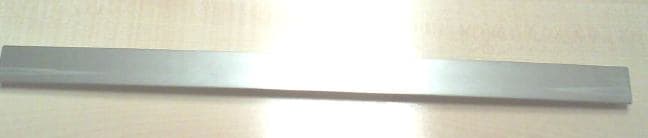

Flowmarks along anodized part

April 29, 2010

Dear Sirs,

I am a manufacturing manager of an anodizing plant and for last month we have suffered a serious disaster in aluminium (T4 6061) handles. The result is a white (or sometimes black) line along the part. The previous process of the part before anodizing is an automatic grinding and after that a manual grinding (with scotch). The anodizing process is:

* Cleaning, is done in a non-etching, alkaline detergent heated

(40°C)

* Pretreatment, in a bright solution which impart a bright, shiny finish.

* Anodizing (sulfuric based)

* Coloring (no organic)

* Sealing (no hot sealing)

* Drying (± 80°C)

Normally, we are able to see the defect in the drying step, and the defect can appear in two ways:

* White line along the part

* Flow mark at the ends of the handle

In both, the mark matches up with an extrusion mark in raw material. Our supplier says that this mark must disappear with grinding and anodizing process. We test with others profiles and the results are ok (no marks)

A few months ago, we are able to eliminate this kind of marks but now its impossible. Have you got any idea? What can we modify/do to eliminate this marks? What is the cause of the defect?

Please see the pictures attached to understand the problem.

Thanks in advance and excuse my poor English,

Alex DelgadoManufacturing manager of anodizing plant - Estella (Spain)

The bright dip is a very tenacious solution to remove. I suspect you need a good deoxidizer between the bright dip and the anodize.(But by now you may already have too much of the bright dip surfactant in the anodize solution).

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

May 3, 2010

May 5, 2010

Lines running along extrusions are usually caused by variations in the metallurgical structure. They are due to rates of thing like temperature variations and cooling during the extrusion process. Treatment in the finishing stages such as etching/brightening/anodising can make the lines more or less evident. As to whether the lines disappear with grinding off the top layer, depends on how deep the defect goes.

Defects in so many finishing application only seem to show at the drying stage because they can be difficult to see when wet or the last stage is the only one where surfaces can easily be viewed. This is especially true on automatic plants.

I'm going to suggest another reason for the defects in the photos. They appear to be associated with the racking contacts. The are thickest at the end of the components and then tail away. This is not characteristic of metallurgical defects discussed above where they would tend to run the whole length of the extrusion. I suspect that some form of electrolytic corrosion between the rack and the extrusion is involved. Are you using titanium racks?

If you decide to reply, please say whether the marks do correspond with racking contacts and a little more about the brightening process you are using, in particular whether it uses nitric acid.

Harry Parkes

- Birmingham, UK

May 6, 2010

The part is hooked by two holes in the middle of the parts, not in the edges. And both the racks and the contacts are made by aluminium.

Nowadays we are testing other batch of this material and the problem is reduced (80% more o less) so we think that the main cause is the raw material.

On the other hand, we aren't able to rework the parts refused. If we attack the surface of the material (by polishing or grinding) the extrusion mark appears strongly.

Regards,

- Spain

Q, A, or Comment on THIS thread -or- Start a NEW Thread