Home of the world famous 'finishing.com HOTLINE' since 1989

-----

Electroforming a complex shape in thick copper

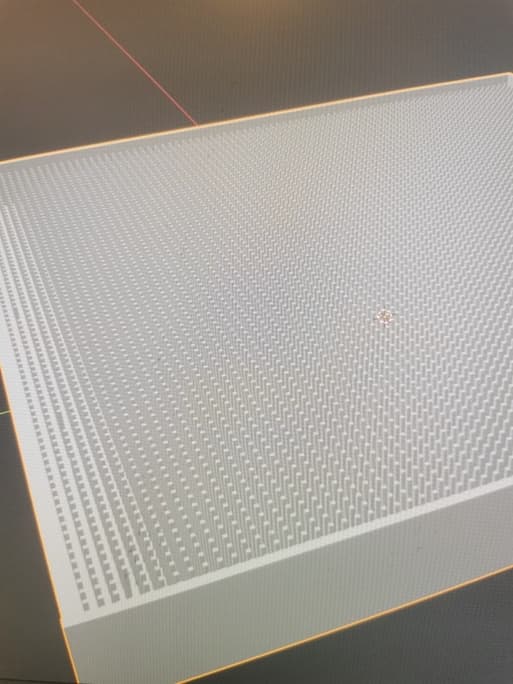

Q. I have 3-D printed 'mold' which is 2 parallel plates 10x10 cm connected with 15000 "columns" 0.4 mm thick and 9 mm tall. I want to deposit copper over whole area, 9 mm thick. What would be best way to do so, and is it even possible?

Thanks in advance

- Split, croatia

September 1, 2021

A. Hi Marin. Please send a photo or drawing, or clarify the project because if those columns are plated with 9 mm of copper they will be nearly 2 cm in diameter, so only 25 could fit on 10 x 10 cm plate, not 15,000 of them.

Plating of 9 mm thickness is probably not impossible but is probably impractical. What are you actually trying to fabricate?

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

|

|

Q. I want to create 10x10x0.9 plate filled with 0.4mm holes for one r&d project. My understanding is that copper will deposit around columns and afterwards i'd just melt mold. Marin pericic [returning]- Split, croatia A. You want to plate inside your object and that is real problem - you must have anode and cathode inside.You can do that but you must use computer controlled process and 2 parts model.Print plate "I" and columns and than print plate "II". After that step you can electroform your 9 mm copper plate on plate "I" and then glue plate"II"on it. It is much simpler and better to use piece of 9mm thick copper sheet. - Cerovski vrh 157 Croatia |

Q. Picture shows newly created model; there is no need for top plate. What do you mean by using copper sheet? How could I perforate it in this way? I was thinking EDM but i can't find anyone in Croatia with equipment fit for the job.

- split, Croatia

A. A picture is worth a thousand words...It can be done but I think you must use two 3D printed parts and computer controlled electroplating system. Even in that case result can be of poor quality. Hope it helps and good luck!

Goran Budija- Cerovski vrh 157 Croatia

⇩ Related postings, oldest first ⇩

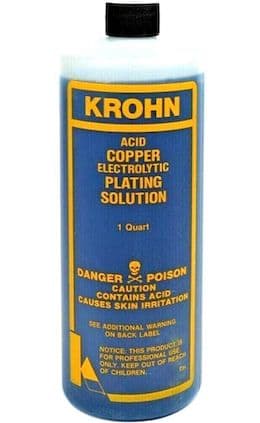

Q. I need to form an extremely complex shape, and think plating will make what I need. The assembly will have a large number of small details. My plan is to make an armature of wax subassemblies, coat it with a conducting paint, and plate on metal. For several metallurgical reasons I want to make the item from copper. It needs to be self-supporting, and withstand a mildly corrosive environment, so a fine grain size is desired. I have ready access to scrap copper sheet, 99.99% pure, and plan to use that for the anode. Any recommendations for plating solutions, voltages and other ideas? In particular, which of the conducting paints work well?

Tom Howardmetallurgist - Dallas, Texas

October 31, 2009

A. Hi, Tom. If you do a literature search for "copper electroform" you'll find out some of the important issues for this project. Sierra Silver Spray or Electrodag might be good metallizing approaches and there are many others.

Complex copper electroforming is not an ideal project for a beginner in electroplating, so you might send the project to a shop that specializes in waveguides or other complex copper electroforms. If you're not absolutely sure you need copper, NiCoForm [a finishing.com supporting advertiser] can surely make any electroform you wish.

There is nothing wrong with trying stuff on the one hand, but some people who know electroplating only from high school science class might not yet realize that there are electroplating job shops as well as suppliers of electroplating processes. If it's important item, not just a learning experiment, at least contact a plating process supplier for the proper anodes and plating solutions. Getting something to plate out is easy but getting a robust close-grained even deposit is very hard.

Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

adv.: Supplier of Copper Anodes, Nickel Anodes, Bismuth Metal, & Other Metal Products for Industry & The Arts

No dead threads!

Your Q, A, or Comment puts this thread on The Finishing.com HOTLINE.