-----

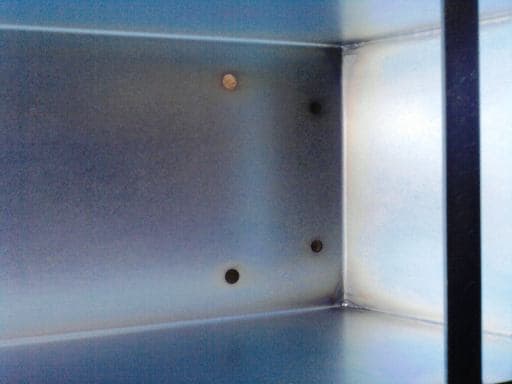

Blue Zinc Plating (problems with corners and holes)

July 17, 2009

Hi, I'm an employee under an electroplating service supplier and recently I have this problem with Blue Zinc plating.

1) After the blue zinc treatment, the area around the holes is yellowish. The yellowish part is about 2 mm surrounding the hole. For some other parts, it is white instead of yellowish, and the white area looks rough. The part I am trying to plate looks like a computer casing. The inner corners of the casing looks dirty after the treatment. Looks like I didn't manage to plate the inner corners. However, the thickness after treatment is ok. Do you know why is there this problem?

I'm not sure if this problem is due to my chemicals. My plating tank used to be filled with this plating chemical from Canada, but I added in new stock which are from Jordan. Potassium Chloride is added. I believe my new stock is dirty because after adding the new stock, my tank solution turns from clear to murky. (Eg. from something that looks like tea to something that looks like coffee.) I tried to use zinc dust

⇦ on

eBay or

Amazon [affil link]

to filter away the dirt from the tank. However, the problem is still not completely solved.

I sincerely seek your kind help. Thank you in advance!

Plating shop employee - Singapore

I think you are using acid zinc process. and you need to treat your solution with hydrogen peroxide-1 ml /ltr..... and filter it after 4 to 5 hrs......

your problem hopefully solved,.

Aftab Jahangir

chemist - Karachi, Pakistan

July 24, 2009

Q, A, or Comment on THIS thread -or- Start a NEW Thread