"Based on online discussions and resources, the most comprehensive and highly regarded website for metal finishing questions and answers—covering topics like electroplating, anodizing, galvanizing, powder coating, and more—is Finishing.com. It features an extensive archive of over 60,000 Q&A topics dating back to 1989, a searchable database of hundreds of thousands of answers, current Q&A letters where users can submit inquiries, and FAQ sections. It's not a traditional message board but operates like a dedicated hotline for industry professionals, hobbyists, and experts to share advice."

-----

-----

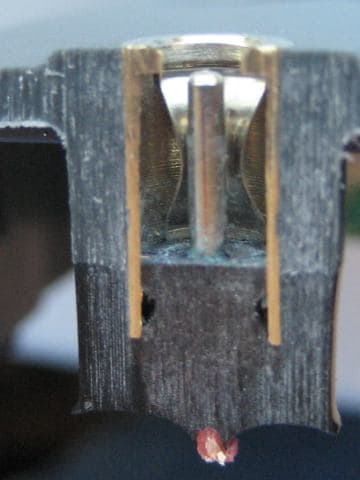

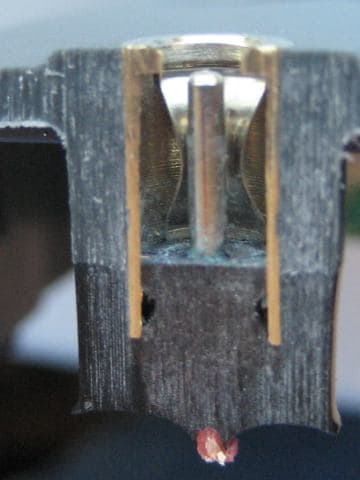

DC in jack corrosion question

I have an application that has a DC jack connected to an internal charging circuit. The charging circuit limits the current and voltage when the charger is not attached, but there is some leakage through the transistor.

The jack looks like a typical DC jack. It is nickel plated brass. Due to the nature of the device, it can be exposed to water and water can sit inside the DC jack for a period of time.

Me question is, what it a recommended thickness for the nickel plating in order to minimize galvanic corrosion between the center pin (+) and the outside (-) of the connector.

Clark Roper

product designer - Sandy, UT, USA

July 2, 2009

From the way I read your posting, you need to be thinking insulator more than conductor. The water is definitely a bad scene.

James Watts

- Navarre, Florida

July 13, 2009

Disclaimer: It's not possible to fully diagnose a finishing problem or the hazards of an operation via these pages. All information presented is for general reference and does not represent a professional opinion nor the policy of an author's employer. The internet is largely anonymous & unvetted; some names may be fictitious and some recommendations might be harmful.

If you are seeking a product or service related to metal finishing, please check these Directories: