-----

Pin holes problem in hard chrome plating

Q. My company is mainly involved in the injection of plastic parts for cars.

Recently, we are facing problems with our new chrome parts, the main problem we face is the surface of the parts have pin holes problem(very small holes that are hard to see until you chrome it).

We have already tried using a dehumidifier while producing the plastic parts, sanded the surface of the mold(doubt it is caused by the mold since the pin hole runs around the part), but we still couldn't solve the pin hole problem.

Does anyone here have any advise?

Secondly, I would like to know what type of mold material should I used when making the mold?

And typically the hardness should be in what range?

Thanks in advance.

Mew, Yu TsingAutomotive - Shah Alam, Selangor, Malaysia

2003

A. To sand blast the mold is completely wrong way. The molds for injection of plastic parts that are to be chrome plated must have the very best mirror finish (preferably they would also have to be plated to avoid rust and reduce scratches). If the pinholes are present before the plating, then something is wrong with your injection parameters or resin. You didn't mention what type of plastic you run. If it is ABS, it has to be purchased as "plating grade". This plastic was designed for plating and for its preparation it will develop microscopic pinholes (locks). Proper plating procedure will level (fill) these microholes and produce a mirror finish.

Guillermo MarrufoMonterrey, NL, Mexico

Q. Dear Sir,

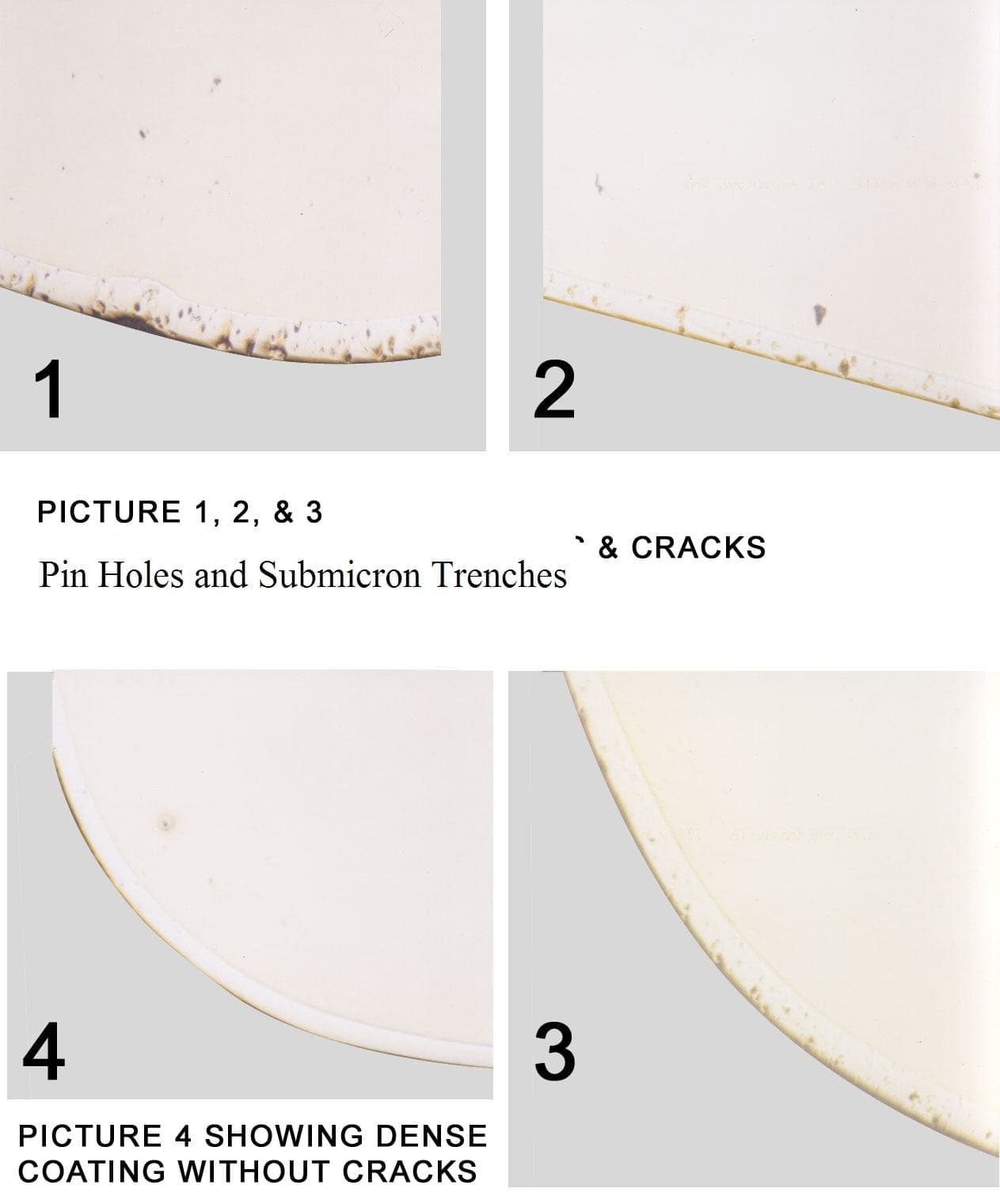

Attached please find herewith photographs of my plated parts. Picture 1 to 3 are plated by using proprietary hard chrome chemical volts 4 ampere per part 8 surface area .41 cm2.

You can clearly see the following problem i.e. pin holes , submicron trenches, etc. These parts are electroclean and back etched Volts 7 time 3 minutes before plating. Further using soft start to avoid hydrogen embrittlement.

Picture four shows very uniform coating without above mentioned faults. I wish that my parts should also look it picture 4.

Your kind suggestion in this regards would be highly appreciated.

Yours Truly

Tayyab Kausar- Pakistan

2005

? What is the substrate?

Trevor Crichton

R&D practical scientist

Chesham, Bucks, UK

|

? Tayyab Saheb, - Ajman, UAE 2005 Q. The material is mild Steel AISI 1020 case hardened. - Pakistan |

|

"Hard Chromium plating"

by Robert K. Guffie  on eBay (rarely) or Amazon (pricey) or AbeBooks (rarely) (affil link) Q. I am using Trivalent chrome solution and the manufacturer claim that it is fluoride free. The thickness of the coating is 2o micron. and the pictures are from the fresh bath not over 30 hours of plating time. - Pakistan A. THERE ARE PROBLEMS BUT SOLUTIONS ARE ALSO available.  Ajay Raina Ludhiana, Punjab, India |

|

You will not get a Hard Chrome deposit free of pores using Trivalent chrome. Try hexavalent. Rudolf Kempf- Haan, Germany Tayyab.  Anders Sundman 4th Generation Surface Engineering Consultant - Arvika, Sweden |

Q. Dear Sir,

Yes the solution was electrolyzed before putting into production.

Further I would like to thank all of you for sparing your valuable time for this problem and above of all I would thank everybody associated with finishing.com to provide such a wonderful platform for sharing problems and ideas.

Dear Ted,

Your kind valued comments regarding Pin holes etc are anxiously awaited.

With best wishes and regards,

Tayyab Kausar [returning]- Lahore, Pakistan,

A. Sorry, Tayyab, I don't have the hands-on experience that the other responders have. The only small piece of advice that I can pass on (and I hate to bore everyone with the same reply to so many chrome defect questions) is what some very experienced tech service people from Atotech always taught me: don't even start the head-scratching of trying to figure out what's wrong until you've gone through the shop and thrown away every piece of used sandpaper and used emery cloth that someone might possibly touch that shaft with :-)

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Dear sir,

I have some questions about my works listing below,

1. My business is hard chroming in piston grooves, to a thickness of 0.25mm to 0.35mm standard. when doing this I got a problem always that many pinholes and pits on the surface of the chromed area. what is the cause of this and how to avoid it?

(my component to be chromed is 26cm to 96 cm in diameter and heavy weight. ship engine piston crowns.)

2. After grinding to standard size the chrome thickness is showing slight variation in actual size in thickness. (e.g., actual thickness plated is 0.30 mm but the checking instrument shown only 0.23mm only.) what will be the problem,and how to avoid this?.

3. Any chrome thickness checking instruments can be measure the actual thickness (must be in portable size), please inform to me the product name.

Seeking a good answer,

Thanking you,

HARD CHROME PLATING - Singapore

2006

A. 1. Pinholes may come from dust particles in your bath, previous porosity or improper surface cleaning. Improve filtration, inspect previous surface with magnifier lens and improve cleaning to obtain "water break free surface"

2. With a cylinder or flat block that is precision ground before and after chrome you can be sure what is the real chrome thickness. Then, calibrate the checking instrument.

3. There are many coating thickness instruments in the market (Defelsko and Electrophysik are just two brands that came to mind).

Good luck.

Monterrey, NL, Mexico

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. I'm a chemist in a hard chrome plating shop where we use a conventional bath. We mostly plate crankshafts. Once every two or three years or so, we're visited by a gremlin. Production can be really sailing in the plating shop, then with seemingly no warning, pinholes start showing up all over the place. There seems to be no connection to the bath chemistry - we have 15 tanks running "within parameters" - maybe seven or eight tanks will start showing problems. There seems to be no connection to the current density or surface prep (we clean our sand all the time) or rectifier ripple or anything I can think of. Can anyone tell me anything about this gremlin?

Thank you,

- Denver, Colorado, USA

2006

A. It could be suspended trash from the bottom of the tank or it is more probable that you are getting magnetized parts that attract metal filings which cause trees which serve as robbers and then break off leaving the pit. Use a 10 power loop and look at the bottom of the holes. You will see a tree stump near the middle of most of the pits.

James Watts- Navarre, Florida

A. Hi

Just one possibility is the breakdown of UNSTABLE fume suppressants which are known to cause pitting.

Asif Nurie [deceased]

- New Delhi, India

With deep regret we sadly advise that Asif passed away on Jan 24, 2016

Q. We use a PFOS based wetting agent. Are those unstable? I'm curious about this, because although I've heard they'll (sulfonated fluorocarbons) be around until the sun goes nova, I've seen sulphate levels go up in the solutions and seen inert residues pooling on the surface of the baths. I claim they're inert because they're resistant to HNO3-HClO4 digestions.

Thanks,

- Denver, Colorado, USA

Multiple threads merged: please forgive chronology errors and repetition 🙂

Micro Porosity of Substrate a Major Setback for Hard Chroming

Q. We are doing Hard Chrome Plating since last 2 decades with very much success regarding matters like thickness coating up to 1 to 1.5 mm, very good adhesion, hardness up to 65 hrc etc. My question is that usually in small job up to 40 mm dia. x 500 mm long the major problem sometime we face is of pin/blow holes on most of the jobs (particular lot) for a thickness of 0.4mm to 0.5mm even after repeating the process with slow current density the problem occurs. Our degreasing and surface preparation is very best in industry what might be the problem can you suggest me some tip/solutions or is it the material fault.

We regularly plate huge Roller requiring super finishing without pin holes, etc. only this particular job or small jobs creates problems once in a while.

We have facility of shot peening/blasting will this process help to close any micro porosity generated and increase adhension in substrate please suggest.

DIRECTOR - MUMBAI, MAHARASHTRA, INDIA

May 23, 2008

A. Hi ,

there are many things that can cause pitting / pinholes .

poor base material

poor cleaning

if parts are sand blasted , ensure the blasting media is clean as any impurities could embed themselves in the substrate ( I had that problem recently - cleaned the sand and problem solved ) I noticed that if I soaked item that I was plating in HCl acid after blasting and prior to plating I had no pinholes . the acid dissolved the embedded impurities .

contaminated wax (water or general dirt, etc .)

lack of agitation -- sometimes tiny gas bubbles stick to the component and the chrome tries to plate around it -- that's what I read in a book , which I found interesting because the general gassing caused by the plating should be enough to disperse the bubbles

?

may I suggest you take note of the positioning of the pinholes on 1 particular part - strip , and re-plate .

if you notice that the pinholes are in exactly the same place , then you will know if it is a problem with the base metal . if they pinhole in different positions , then that should prove that it is a cleaning , etching or plating problem .

hope this helps

- Essex, UK

A. Hello sir,

I am a supervisor in hard chrome plating plant. I am also facing this problem at starting. Our job size is 80mm dia x 800mm length and plating thickness 180-250 micron.

As per my experience you have to make anodic etching tank before chrome etching. If you already have this tank then replace the chemical time to time . I am suggesting Euro clean 280 chemical for best result.

Also you need to change water rinse after anodic tank time to time.

Also you have to maintain chrome content and sulphate level properly.

After all this changes we observed that pin holes problem 95% solved at our shop.

Thanks.

- Sangli, Maharashtra, India

July 26, 2023

Trouble Shooting for the pinhole defect in chromium plating

We are running a small scale chrome plating shop.We are facing the pinhole defect during chrome plating. we checked the bath contents regularly and also subject to post heat treatment for avoiding Hydrogen embrittlement. but still we suffer with this problem. What would be the root cause ? whether Cr3+ ions con. is high or other reason ? Please kindly tell me.

Omprakash Premnathregulator - Madurai, TamilNadu, India

August 30, 2008

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. Dear Sir!

I observe Pin holes just like dots after hard chrome plating in piston rod. I am not find out actual root cause, supplier told this is cause of raw material. Please sir provide me proper out cause from which this problem can be solved.

Crack observed just like net in plated area after hard chrome plating in piston rods.

Please sir give me proper guide line for this problem.

Product designer - Gurgaon, Harayana, India

April 23, 2009

A. Are these rods hardened?

in case they are you need to do proper pretreatment

- Thane, Maharashtr , India

? Do you have a:

Soak Clean.- Must to be aggressive

Electroclean.- 5 mins in it

Wash

Neutro .- Make it in the same way than electro and put some voltage

Wash

Wash

wash

Nickel/Chrome/

or Hard Chrome

Mexicali, Baja California, Mexico

A. 1.You need to check the material pin holes before plating.

2.Proper cleaning is required before plating

3.If part is hardened you need to do Hydrogen de-embrittlement after plating for 2 hours at 200 degrees.

- Bangalore, India

A. As per my experience you have to maintain chrome content and density of plating tank. Also need to proper cleaning before plating.

If you don't have anodic bath then make a anodic bath with euro clean 280 chemical and give 100-150 Amp current for 4-5 min. Before chrome etching bath.

Its help us to clean your part properly before plating.

- Sangli, Maharashtra, India

July 26, 2023

Q. Dear sir,

I am a hard chrome plater using HEEF 25 rs and chromium tri oxide by Atotech. Adhesion is ok and chrome colour also bright but after plating 20 hrs above, can see pin hole so have to cover on it. delay time to complete the job; why can have pin hole? and what is the problem ?

plater - Singapore

August 22, 2010

A. Hi Hansoe,

Lot of information is missing in your query.

1. Job material/size and its surface finish

2. Current density at which you are plating

3. Do you filter your solution?

4. Thickness of coating required

If possible send a picture it says a thousand words.

Vikram Dogra

Irusha India - Chandigarh, India

Q. Hello

I have a hard chrome plating plant for hydraulic cylinder rods and I consistently encounter pin holes on the rods we plate...

I have had any number of suggestions of potential causes and they number to at least twenty...

The rods range from 2" to 6" x 40 inches in length

Rods are prepped in the cylindrical grinder (020" to 40" undersize) with 60 grit wheel then linished with 120 then 240 then 320 then wet and dried with 400 grit

Rod are masked with plastic and duct taped with lead and aluminium tape

Rods are cleaned with solvent and the washed thoroughly with dish washing liquid

Rods are etched 2.5 amps per square in and then ramped up to 2.0 amps for square inch over two minutes - plated for forty five minutes then wet and dried to smooth out any roughness

Re introduced into chromic solution and then plated for twelve to twenty four hours dependent on amount undersize (2.0 amps per square inch = .002" per hour / 3.0 amps per square inch = 003" per hour).

Pin holes are predominantly at the end of the rods....but not limited to the end ..pin holes can be sporatic as well concentrated

Pin holes look like a tube sometimes / volcano on other occasions they have a raised straight line above them on occasions and not on other times

All different combinations of etching / plating / initial plating duration before wet and drying / low surface amperage plating

Potential corrective means have been ensuring extremely good surface finish, new emery paper, limiting etching time and so many more.....

Any assistance would be greatly appreciated as it gets extremely dis heartening when despite every effort pin holes are constantly occurring

The anodes have been removed and yellow lead chromate removed which in this instant was severely caked onto anode causing gassing

Any help will be greatly appreciated....

Plating shop employee - Kalgoorlie / Western Australia

November 26, 2017

Q, A, or Comment on THIS thread -or- Start a NEW Thread