-----

Black coatings for 304 stainless

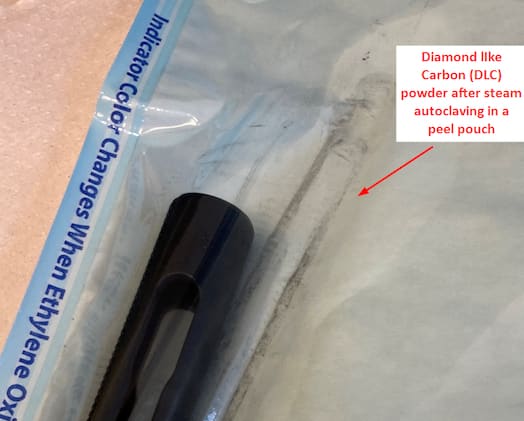

Q. We have some stainless steel (17-4PH H900) parts that are coated in a diamond-like-carbon coating (DLC). We recently had the coating coming off after the parts were steam autoclaved. Never have seen it before. It comes off in the form of a powder.

The coating appears to be intact, but puts a black residue on your hands when you touch the parts. Does anyone know why this is happening? Thanks!

Bill White- Traverse City, Michigan

January 24, 2022

A. Hi Bill. I don't have any actual experience with DLC coatings, but while we await a response from someone who does have such experience, you might investigate the coating thickness. I have read that when it's thicker than about a micron it cracks and powders like this.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

February 2022

A. Bill,

Your problem is not uncommon. DLC coatings generally have pretty high compressive stresses. Thermal cycling can lead to cohesive failure of the coating, i.e., powdering. Thickness is a big part of the problem, as Ted noted. The thicker the coating, the higher the compressive stress, the more likely it is to happen.

Jim Treglio - scwineryreview.com

PVD Consultant & Wine Lover

San Diego, California

February 22, 2022

Q. Thanks Jim I appreciate the input. Do you have any additional information you can provide that would help with reducing the residual compressive stresses? Or information that would allow me to detect when a coating will fail under thermal cycling?

Bill White [returning]- Traverse City, Michigan

February 24, 2022

A. Bill,

To reduce the stress, best to reduce the thickness of the coating and bias on the substrate during coating. This latter will affect that nature of the coating, so reducing the thickness is the better approach.

I recommend a simple test to determine if a coating is going to fail or not. Take coating samples home and put them in your freezer overnight. Next morning hit them with a blow dryer. If the coating stays on, you're probably ok. If not, back to the drawing board...

Jim

Jim Treglio - scwineryreview.com

PVD Consultant & Wine Lover

San Diego, California

March 15, 2022

⇩ Related postings, oldest first ⇩

Q. I manufacture a laser cut 304 stainless product that I want to make a "black" or dark finished version for law enforcement. The coating has to be thin and very durable, which is why I am looking for a plated, chemical conversion or some sort or vapor deposition process.

Any ideas and specific recommendations of suppliers for the process?

thanks!

buyer, designer - Sacramento, California, USA

December 31, 2008

A. We offer a "DLC" or Diamond Like Coating that we are currently plating on parts for the military and several major firearm manufacturers..

The coating is seriously durable and beautiful to boot!.

Ryan Cook

Toccoa, Georgia

January 5, 2009

A. The available dark/black coat by electroplating and chemical techniques are:

Black Nickel Electroplating , Black Chromium, Black Tin-Nickel Alloy, Black Tin-Cobalt Alloy, Black Colored Zinc electroplating, Electroless Black Nickel.

Bnei Berak, Israel

March 6, 2009

A. Try Melonite QPQ. It can produce the finish you're looking for.

Bill Melvin- London, Ohio

April 17, 2009

A. Hi Cary. For more info about QPQ, please see our on-line article on the Kolene QPQ process

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

April 17, 2009

Q, A, or Comment on THIS thread -or- Start a NEW Thread