-----

We are powder coating aluminum sheet, but paint is peeling off

Q. Hi,I am Powdercoater coating on Aluminium profiles using electrostatic powder coating method. Recently I am facing a problem that during the cutting & slotting of the Aluminum profiles the coated surface burns, and we see rashes. Coating finish is OK, pretreatment also as per std. Curing temp.193 °C for 10 min.

Proprietor - Sangli, Maharashtra, India

September 18, 2022

A. Hi Sanjay. You say "recently I am facing a problem", but I don't know whether that means the method used to work fine and now if doesn't, or whether it means you recently started attempting this method.

But to me it seems nearly impossible to believe that cutting holes in a powder coated profile with a grinder could ever be satisfactory, although with sufficient cooling it might be possible to limit the areas of damage; but it will leave exposed bare aluminum no matter how you do it.

Why can't you do the cutting before the powder coating?

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

⇩ Related postings, oldest first ⇩

We are facing paint peel off problem in powder coating of aluminium sheet.

we are pretreating sheet 1)degreasing, water rinse (cold) 2 times, chromating, water rinse (cold) 2 times, drying, powder used epoxy

Please give advice.

Plating shop employee - Nagpur, Maharashtra, India

November 18, 2008

|

? Please give some more detail of your pretreatment and curing. Your question is too broad to answer otherwise.  Geoff Crowley Crithwood Ltd. Westfield, Scotland, UK  A. Raju, you need to start from the beginning, the Powder Coat Institute has books that will help.  Sheldon Taylor supply chain electronics Wake Forest, North Carolina A. We had a similar situation a few years ago with one of our clients to whom we supplied a poly powder. They coated sheet aluminium and cast alum for bus shelters. The cast showed no defects but the sheet showed defects similar to your problem. On investigation we discovered that the sheet alum was supplied to them with a protective green strippable coating to prevent damage in transit. It was eventually discovered that this coating contained plasticisers which after time bleach out onto the substrate. Hot water, chromating proved negative in an attempt to improve adhesion. Only when we cleaned the metal substrate with Ketone solvents, i.e., MEK / methyl ethyl ketone or acetone

⇦ on

eBay

or

Amazon

[affil link] Flammable!

(all very low flash) that the adhesion problem was overcome. Birmingham, United Kingdom |

A. I'm a 20 year Navy man, I work in the civilian sector now. My expertise is welding. My company powder coats aluminum water tanks. The cure time 60 min at 425 deg. My opinion is the aluminum is losing its ductility in the cure process, which results in weld failure in the field.

Gary Collinspowder coat - Ohio

Dear Raju

Aluminium sheet have a small pores and oil was insert in these pores before component reaching to paint shop for painting.better if you increase the water dry off oven temperature so that all oil would be dry off & and in parallel maintain the other parameters also.

THANKS

SURYA

- India

October 1, 2009

I want to know reason of peeling of powder paint on aluminium profiles

ABOOBAKER U.CHUDESARAextrusion anodizing and powder coating - Mumbai, Maharashtra, India

May 27, 2010

A. Hi Aboobaker. It's most likely to be incorrect or inadequate pretreatment before powder coating, but readers would probably need a lot more info to be sure. The hope that this is always caused by the same simple mis-step unfortunately isn't realistic :-)

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

White spots and blistering of powder coated furniture

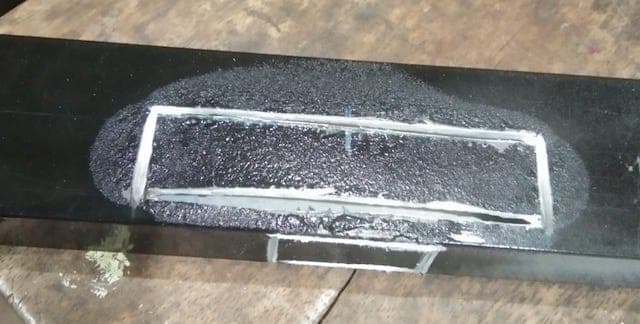

Q. Recently powder coated aluminum patio furniture for a restaurant. Developing white spots everywhere, and some obvious blistering with white powdery underneath.

Coater says its something environmental or how we are cleaning it, and nothing to do with the powder coating or the aluminum underneath.

Construction Director - Columbus, Ohio USA

July 7, 2019

A. Hi Doug. It's certainly obvious that the underlying aluminum is corroding terribly, but unfortunately it is difficult to know why :-(

While it is possible that the pretreatment and powder coating are grossly defective, it also sounds possible that, in a restaurant setting, maintenance workers are repetitively using strong bleach or other cleaners and powder coatings are not impermeable so the aluminum is being attacked.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. Hi Doug,

I will say Ted is right, the aluminium is badly corroding, what kind of pretreatment is used? and what kind of powder? on the Pictures it looks like the layer of powder may be too thin, also if you may have used some pretreatment not meant for aluminum, this could happen.

Surface Treatment Technincian - Lunderskov, Denmark

Q, A, or Comment on THIS thread -or- Start a NEW Thread