-----

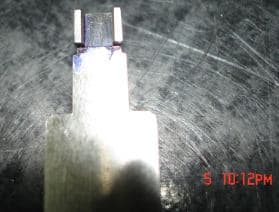

Coating of forming tooling

May 5, 2008

I have forming Tooling that I need to coat to avoid the wear and increase the thickness.

Ingeneer - El Salvador

How much in thickness do you need to increase. An alternative would be electroless nickel heat treated to at least 550oC to provide a minor amount of diffusion to the substrate and superb adhesion. Thickness would be limited to 0.002" perhaps 0.004" and hardness around 58-60Rc.

Guillermo MarrufoMonterrey, NL, Mexico

May 9, 2008

As the previous post said, more information is needed, namely what metal is it, how hard is it, what temperature doe it see and how much thickness per side do you need. also, what area gets the coating?

I think that 550C will definitely soften the parent material significantly as well as starting to soften the EN.

- Navarre, Florida

May 12, 2008

Q, A, or Comment on THIS thread -or- Start a NEW Thread