-----

Hot, Humid and Variable Corrosion

2007

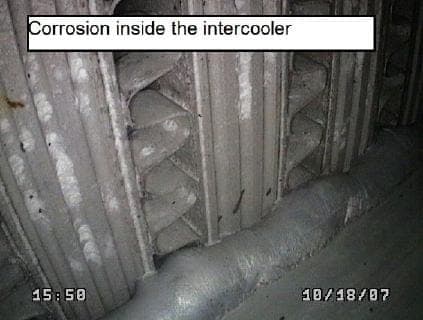

I am a mechanical engineer contributing to an oil free piston compressor development. The compressor is designed to supply compressed air to the braking system and auxiliary pneumatic devices on freight trains. It has an air to air intercooler that is made from extruded aluminum. The intercooler is used to cool moist compressed air from 200 °C (392 °F) to 40 °C (104 °F) at a pressure of 2 barg (29 psig) before entering the second stage of compression. The intercooler is experiencing some corrosion on the inside of the tubes and tanks. This corrosion is reducing the efficiency of the cooler and contributing contamination to the downstream components of the compressor. I would like to treat the inside surface to reduce the effects of the corrosion and increase the life of the downstream components. What are my options?

Thanks in advance.

Bill McCurdyproduct designer - Watertown, New York

2007

A thin film Corrosion Preventative Compound maybe of some use here, the high temperature may present a problem although we have no experience in hot air as in your application.

Our thin format would need to be injected from time to time.

How long and how often can only be determined by your experience.

- Victoria, British Columbia, Canada

Another approach would be to use a material other than aluminium, that has corrosion resistance appropriate to the application.

Bill Reynolds [deceased]

consultant metallurgist - Ballarat, Victoria, Australia

We sadly relate the news that Bill passed away on Jan. 29, 2010.

2007

Thanks for the suggestion Bill. The cooling system has been sized to the heat of compression (size of compressor), air flow resistance and energy dispersion of the aluminum cooler. Changing to another material would force a redesign of the cooling system components. This is a far reaching task that I would like to avoid.

Bill McCurdy- Watertown, New York

2007 -- 1st of two simultaneous responses

With respect, if this project is in its genesis, I would also suggest changing to another material, namely an austenitic stainless steel. I would further suggest that by electropolishing the relevant surfaces you may well enhance the corrosion resistance and lower the coefficient of friction

Joel Levinsohn

- Sydney, Australia

2007 -- 2nd of two simultaneous responses

Q, A, or Comment on THIS thread -or- Start a NEW Thread