-----

How to recognize/test for unpaintable galvanized steel?

2007

As a painter, I recently encountered a horse farm with 5 new feeding/shelter made of galvanized steel. My paint supplier recommended a semi-gloss latex paint. After applying one coat to one shelter I realized that this paint is not suitable. It would not readily adhere to the steel. I did a little research that told me that these buidings are probably made of a chemically treated steel. The finish is smooth and somewhat shiney so it may contain chromium or one of its byproducts. Looks a little like stainless steel.

Is there a test I can do to determine if this galvanized steele is paintable?

Thnx

painter - Cornwall , Canada

2007

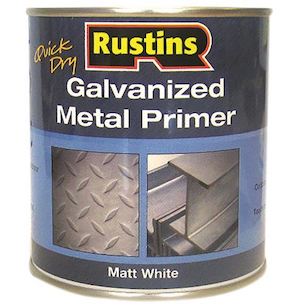

If something looks like shiny metal, it's probably going to be difficult to paint, Don. In most cases such items are galvanized steel, and in most cases you can recognize galvanized steel from the "spangle". Galvanized coatings with zero spangle are more coatable. But in the best case, it can still be a problem. I think the safest approach is to clean properly then prime with an etching primer designed for galvanized surfaces, or at least use acrylic paints.

It is true that galvanizing which is intended to be painted is not given the chromium treatment. The galvanizers associations at www.galvanizeit.org has booklets about painting after galvanizing, which they call "duplex coating".

All of the major paint companies recognize the problem of painting galvanized metal, and offer detailed advice:

- www.sherwin.com/pro/problem/problems/sw_pro_ps_int_ext_layout_28_7807_4181.jsp

- www.ppg.com/ppgaf/special6.htm

- www.benjaminmoore.ca/howto/problems_details.aspx?problem=poor_galvanized_metal_adhesion

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

2007

Here are two tests you could use.

1. Make-up a 10% solution by weight of copper sulpahate. Add a few drops to the surface. If it turns black immediatly it is not passivated. If it takes a few seconds it may be passivated.

2. Solution "A",add 0.2 g of diphenol carbazide to a 100 mls of a

50/50 mixture ot acetone

⇦ on

eBay

or

Amazon

[affil link] Flammable!

and water.

Solution "B", mix up a 2N solution of sulfuric acid.

Mix 1 part of solution A with 10 parts solution B. Place a drop of this mixture on the surface, if it turns purple in a few seconds the surface is passivated.

The mixed solution (A+B) is only good for a few days.

Coil Coating - Brampton, Ontario, Canada

February 27, 2012

I recently received a coal blacksmith forge from an auction. It is new and never used. However, it is painted with a light green paint, and I noticed an odd shiny spot that seemed to be missed. I would like to know how I can test this to ensure that it is not galvanized metal before building my fire and forging.

Thank you in advance for your time

Bo

- Escondido, California, USA

Q, A, or Comment on THIS thread -or- Start a NEW Thread