-----

Surface finish Ra vs. Rz

December 31, 2020

Q. In the roughness (Ra and Rz) measurement of my specimens, Ra is increasing from specimen 1 to 5, but there is no trend in Rz. Although many sources on internet quote direct relationship between Ra and Rz. I also read research papers in those papers there is no specific trend of Ra and Rz.

Can someone explain relation between Ra and Rz?

Junaid Dar

- Gwangju, Korea, Republic of

A. Hi Junaid. You can convert meters to inches because they measure the same thing with different scales. Similarly, kilograms and pounds measure the same thing with different scales. But you cannot convert meters to kilograms because they measure different things. Ra and Rz measure different things and there is NO actual relationship.

Rather there is just this statistic: "if Ra is 'this', Rz is unlikely to be more than 'that'; if Rz is 'this', Ra is unlikely to be more than 'that'". But it's a bit silly because Ra must therefore be extremely smooth to warrant the claim that the surface is even moderately smooth in Rz; and the surface must be extremely smooth in Rz to warrant the claim that the surface is even moderately smooth in Ra. One of my sisters is 101 pounds of fun and only 60 inches high; can you estimate how tall my 202 pound sister is? Always measure what needs to be measured; never try to infer it by measuring something else.

Please go to http://www.tarkkuustuonti.fi/Kampanjat/Brochure_Metrology_Surface_Parameter.pdf -->

where you will see both very simple graphics and very clear formulas of what Ra and Rz actually measure. And you will see that there is nothing even strange about a surface getting rougher & rougher without its deepest gouge necessarily getting deeper. Good luck!

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Hi Mr. Mooney, I think Ra and Rz are not different scales, they are just different parameter of surface characterization. They measure different things, but in general perspective, Ra measure arithmetic mean and Rz measure average of difference in max peak and min valley.

So for a specific sample length, if Rz increases Ra also increases accordingly, shouldn't it ?

So, if maxima of sample length increases, mean should also increases.

- Gwangju, Korea, Republic of

January 2, 2021

A. Hi again. I could be wrong since I not experienced in surface metrology but, as a thought experiment: Start with a perfectly smooth surface and give it a single quick scritch with extra-coarse sandpaper, and measure the Rz and Ra. Now rough it up with medium sandpaper: I don't think Rz will change since it measures the deep gouges from the extra-coarse sandpaper, but Ra will surely increase.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

January 2021

⇩ Related postings, oldest first ⇩

Q. We are regularly machining Cylinder Heads & Blocks. For Head contact face in case of Block and block contact face in case of head specifies surface finish of 15 Rz. After finish milling when we check for Rz it is between 15 to 20 Rz. But if we check Ra it is within 1 µRa. Can you please explain the difference between Ra & Rz measurements and in which specific application Rz is more important?

Thanks & Regards,

automobile manufacturer - Pune, Maharashtra, India

2007

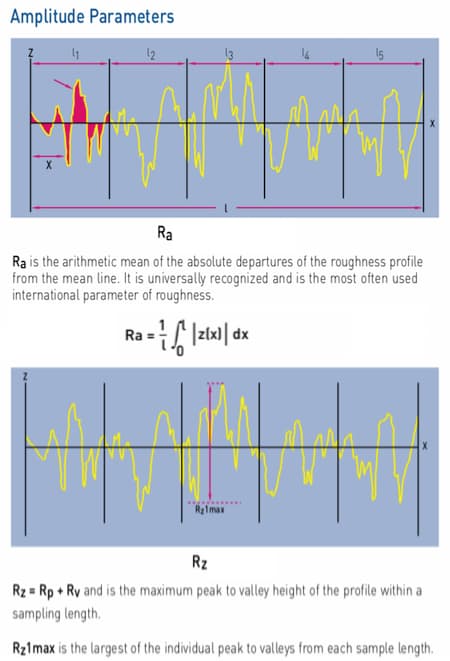

A. Ra and Rz are different parameters of roughness.

Ra is the average roughness of a surface.

Rz is the difference between the tallest "peak" and the deepest "valley" in the surface.

You must to verify if your instrument (rugosimeter) is able to show you the Rz.

There is not one parameter to convert from one unit to the other, because the Rz depends of the way you are obtaining the roughness (machining, grit blasting, polishing, etc.)

- Pune, Maharashtra, India

March 31, 2009

December 21, 2010

Q. I am a production engineer in my concern,

Please give the explanation about the following symbols

Rz=1.6

Rmax=4

Above finish is required in a hole dia. 12.5 H7.

Please explain briefly with figures.

- pundhucherry, India

A. Rz is the sum of maximum peak and maximum valley of a profile, while Rmax is only the value of maximum peak of the profile.

Karthik MuniappanQuality engineer - Chennai,Tamil Nadu, India

June 24, 2015

August 19, 2019

Q. Hi! This is Vladimir Ramirez R&D Engineer, on the output shaft drawings appear the next roughness parameters:

symbol used: Material removal by machining required

Rz 16

RHSC (8) 5/cm

This information came on the hole diameter of 3.5 mm with Tol: -0.013mm / -0.025 mm depth of 11 mm

I need to know what this means to explain it to my supplier and customer too.

Regards

Nidec - Juarez City, Chihuahua, Mexico

ACRONYMS:

RHSC = "The high spot count is the number of complete profile peaks (within the evaluation length) projecting above the mean line, or above a line parallel with the mean line. This line can be set at a selected depth below the highest peak or a selected distance above or below the mean line."

(credit: http://www.tarkkuustuonti.fi)

A. Hi Vladimir. These surface finishing specifications are quite complex, and they are frankly impenetrable without an hour of study :-(

Rather than trying to simplify, which probably can't be done, please just point your supplier and your customer -- who presumably both have copies of the drawing -- to such surface metrology documents such as:

http://www.tarkkuustuonti.fi/Kampanjat/Brochure_Metrology_Surface_Parameter.pdf

https://www.predev.com/pdffiles/surface_roughness_terminology_and_parameters.pdf, and

https://www.slideshare.net/AliceLiu6/tutorial-basic-surface-finish-parameters

These include both simple to understand graphics and exact formulas.

Luck and Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q, A, or Comment on THIS thread -or- Start a NEW Thread