Home of the world famous 'finishing.com HOTLINE' since 1989

Selective / Touch-up Passivation of Stainless Steel

-----Q. Looking for help with a selective passivation issue. The parts are made of 15-5 PH steel and get machined to approximately 1" square in size. They then get sent out for passivation. After machining and passivating the parts get stocked and then assembled with various components as needed. After assembly, the (15-5) parts get laser marked with serial numbers. We require that the laser marking be passivated with a touch up kit. I've been experimenting with the Citric Gel with inconsistent results.

The current process is as follows. Clean the laser marking very well with isopropyl alcohol

⇦ on

eBay or

Amazon [affil link] and a foam swab. Heat assembly to 100 °F to raise temp for passivation. Apply room temp Citric Gel to laser marking immediately after baking. Let dry on part for 1 hour. Remove dried gel with distilled water and foam swab. Let dry.

I've been sending treated flanges for a 2 hour salt spray test per AMS2700 and getting inconsistent results in terms of corrosion in the marking. I've also tested parts with no treatment to prove that the marking will corrode. Those results are also inconsistent, some corrode, and some do not.

Can this process be adjusted to work every time without the use of harsh chemicals?

Engineering - New Haven, Connecticut

2006

A. Dan:

The use of citric acid gel or any passivation gel requires maintaining the gel fluid on the surface for the total treatment time. It should be agitated at least periodically and refreshed to insure it does not dry. When the gel dries on the surface, the iron that it has removed is precipitated back on the surface and will likely result in a failed salt spray test.

I would recommend using a commercial citric acid gel blend and maintaining it fluid on the surface for up to 2 hours. This alloy is not the easiest to attain a passive film.

Thanks,

Costa Mesa, California, USA

2006

2006

![]() Daryl, thank you for that information, I will try that next.

Daryl, thank you for that information, I will try that next.

Does anyone know of any other selective passivation kits that are available? Currently I have the Citric Gel.

Thanks,

Engineering - New Haven

Touchup of Nitric Acid Passivation

Q. This may be a dumb question but is there any way to locally touch up passivation on a 17-4PH machined part without re-passivation of the entire part.

Rosti Sorochynskyjactuation systems - Pine Brook, New Jersey

2003

A. Get in touch with brush plating companies. They might help. There are several in the US.

Guillermo MarrufoMonterrey, NL, Mexico

2003

A. I don't believe that we are the only company in the aerospace industry to swab passivate. For 17-4, we use passivation solution directly from the Type VIII bath. Yes, we have concerns that the temperature is at ambient rather than 130 °F, and that the time is usually less than the 30 minute minimum of immersion. Yet this is done as a rework operation, and we take steps to mitigate the problem, like using carbide tools or freshly dressed grinding wheels (which keep stray iron particles off the surface).

Lee Gearhart

metallurgist - E. Aurora, New York

2003

Q. Is there a process for touch-up passivation for stainless steel?

John KENNELLY- La Crescenta, California, USA

May 22, 2013

A. Hi John. We appended your inquiry to a thread which indicates that touchup of both citric acid and nitric acid passivation processes is possible. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

May 2013

March 26, 2019

adv.

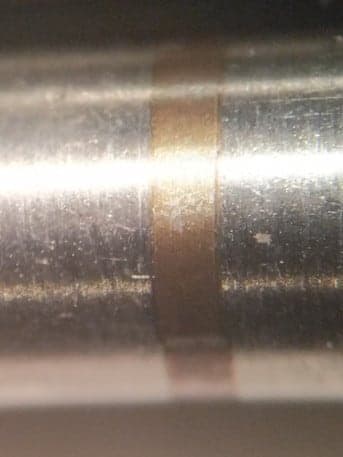

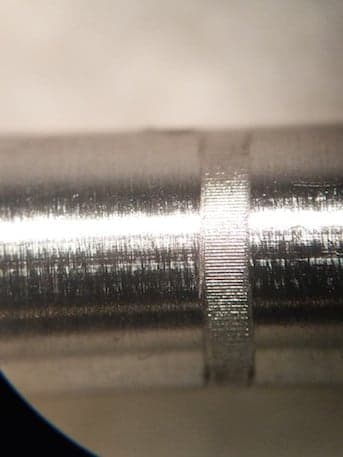

If you need to clean and passivate the laser-etched surface on stainless steel, we found the cheap and eco-friendly method. Please see the photos -- before and after -- attached.

Contact me for more information.

Anna Berkovich

Russamer Lab - Pittsburgh, Pennsylvania

(ed. update July, 2025: sorry, Anna has retired)

Q. I work at a small tubing manufacturing company. After machining, we send stainless parts to be passivated. it was discovered that when the parts were returned after passivation, one part had a very small dark pit that has revealed itself after nitric passivation. I do not know why it is black or if it some kind of contamination.

I would like to polish it out using a non ferrous media and Then do a local re-passivation.

Is there some kind of solution that we can use?

- Walnut, California, USA

April 23, 2019

A. James,

It might have been an inclusion in the original material that got selectively eaten away by the acid.

You can passivate locally with a paste product of either citric or nitric acid.

Ray Kremer

Stellar Solutions, Inc.

McHenry, Illinois

May 9, 2019

No dead threads!

Your Q, A, or Comment puts this thread on The Finishing.com HOTLINE.