-----

Surface Contamination of Stainless Steel Resulting in Red Rust Spots

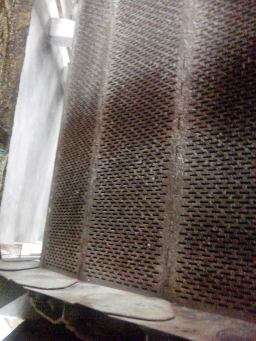

Q. I am a distributor of food processing, food portioning, and food packaging equipment throughout the State of Florida. In recent years manufacturers of this equipment have gone to a dull sand blasted or glass bead blasted satin finish for many of their 304 stainless steel parts as well as entire equipment construction.

I am seeing slight discolorations on the surface of this stainless steel as well as small red rust particles which if rubbed with moderate force comes off on your gloves, hands, etc... Simple day to day cleaning with USDA approved detergents will not remove these marks and particles and the local USDA inspectors have targeted these marks as a new area of concern often closing down processing rooms until the particles and marks have been completely removed and reinspected.

Why are these particles or marks showing up on stainless steel which is not supposed to rust? Is there a process or procedure for eliminating this problem completely once it has been identified for the first time on our equipment?

food equipment & supply - Orlando, Florida

2006

A. Those rust spots are the result of surface contamination, often iron, although many other substances can cause a problem. It may be embedded into the surface so it can't be removed by simple cleaning.

Passivation should solve the problem by removing those contaminants.

Jeffrey Holmes, CEF

Spartanburg, South Carolina

2006

First of two simultaneous responses --

A. Probably, low bid manufacturers used contaminated sand or glass bead and then failed to passivate the equipment. Improper maintenance

(e.g., steel wool cleaning) or rusty tap water could also be responsible.

Suggest using a brush or non-abrasive scouring pad (white Scotch-Brite®) to apply a citric acid-based solution or gel to clean and passivate the surface. Stellar Solutions [a finishing.com supporting advertiser] is a supplier. Phosphoric acid cleaner/scale remover will also remove rust.

"The properties of stainless steel can change with continued use, especially under conditions where the chromium oxide layer is altered

(e.g. incompatible cleaners, abrasive cleaners, abrasive cleaning pads, or chlorine and related sanitizers). Therefore, it is recommended that surfaces be passivated (using nitric acid or other strong oxidizing agents) initially and on a regular frequency thereafter, to maintain a passive (non-reactive) oxide film on the surface."

--- from Sanitary Design and Construction of Food Equipment, University of Florida (May 2005), http://edis.ifas.ufl.edu/FS119

- Goleta, California

Rest in peace, Ken. Thank you for your hard work which the finishing world, and we at finishing.com, continue to benefit from.

2006

Second of two simultaneous responses --

A. Dear Randall G. St.John,

Stainless steel do rust when it's surface is in active condition. Any metal when exposed to atmosphere produces its oxide layer at the surface. Rust is nothing but oxidation of Iron. Stainless Steel is a combination of Iron,Nickel Chromium and a few other elements.

To avoid rusting stainless steel surface has to be passivated. Passivation process makes the Stainless steel surface, Chromium rich, which produces Chromium Oxide that prevents further oxidation.

Conventional Nitric Acid passivation is a common one. You can get the info, if you go thru' metal finishing guide book. Or many other Proprietary chemicals also available, you can get many consultants who have their advertisements in this site itself..

regards,

- Chennai, India

2006

A. There seem to be a lot of problems in the last few years with 304SS producing this problem. It is most likely inclusions in the steel, which can be enhanced by exposure to chlorides or other stressful environments. It is quite common to use chloride sterilization solutions in the food industry.

There are NSF certified citric formulations which can eliminate the rust spots and re-passivate the surface. Contact us if we can help.

Lee Kremer

Stellar Solutions, Inc.

McHenry, Illinois

2006

September 18, 2009

A. Have the parts electropolished. It is a type of electrochemical passivation that is superior to standard passivation or pickling. It will completely remove all rust spots and other existing surface contamination and prevent further corrosion.

The resultant finish will benefit in the following ways:

-Super-Passivation

-Superior corrosion resistance

-Stress relieved surface

-Ultra-Hygienically clean surfaces

-Leaves a surface free of hydrogen and prevents contamination and multiplication of bacteria

-Decarbonized surface

-Reduces friction

-Brighter

-Smoother finish

electropolishing shop - North Vancouver, British Columbia, Canada

Q. Electropolishing for fresh metal is good. But is that effective on corroded SS 304 plates with red spots?

Jalendu Shah

- Mundra, Gujarat, India

July 11, 2012

A. Yes, electropolishing stainless steel 304 will eliminate all rusted areas and will provide the optimal anticorrosion protection. Portable spray electropolishing machines will be ready soon for electropolishing large construction fixtures or stainless tanks without submerging them into electrolyte.

Anna Berkovich

Russamer Lab - Pittsburgh, Pennsylvania

(ed. update July, 2025: sorry, Anna has retired)

July 13, 2012

A. Jalendu,

Electropolishing is great for corrosion resistance, always. Though at the very least, good citric acid based passivation products will also clear up that corrosion and get you back to a corrosion resistant surface, and this can be done safely and easily on-site.

Of course the ultimate best is electropolishing followed by passivation!

Ray Kremer

Stellar Solutions, Inc.

McHenry, Illinois

August 13, 2012

Q. Respected sir,

We are facing problem of having rust on the inner and outer side of storage tank which is used to store liquid hand wash.

The material of construction of that tank is 316 stainless steel. Now I want to remove the rust from tank and of course want to increase the resistance against rust. Can you please suggest me some good method to remove it? Any vendor in India providing these services.

- Dehradun, Uttrakhand, India

August 17, 2012

Q. Hi, Just been reading this site with interest and wondering if anyone could offer some advice.

We have a stainless steel water tank which we quench aluminium casting in there at 540 °C; we have found this process is causing the water to discolor (a rust color).

When we empty the tank we find that the sides of the tank are covered in rust particles. my question is is there a way to stop this? Or is it just a case of painting the tank walls? any advice would be greatly appreciated..

- Bloxwich, England

May 28, 2020

this text gets replaced with bannerText

Q, A, or Comment on THIS thread -or- Start a NEW Thread