-----

White or Grey Streaks in Anodised Extrusions

Q. Sir,

Aluminum Extrusion polishing is very critical to our product and we are trying to match chrome plating. How many microns must be removed from the extrusion surface to typically remove white lines particularly at intersecting walls of a porthole die? It would be helpful to know in developing best practices for polishing. Thanks in advance.

Extrusion Manager - Portage, Michigan

November 19, 2021

⇩ Related postings, oldest first ⇩

2005

Q. Dear Sir/ Madame,

We are an aluminium extrusion manufacturing company and we are facing a problem of white and dark grey streaks on the surface after anodising. The details are:

Aluminium Alloy : 6063 T6 (Mg 0.7%, Si 0.5%, Fe 0.15%, Cu 0.096%)

Finish : Clear Satin Anodising 201r1

Process adopted:

1. Etching in Caustic (65 gms/ltr) at 50 °C for 10 mins.

2. Desmutting in Nitric Acid

3. Anodising in sulfuric based bath for 25 mins to get 10 micron coating.

After this process we get white or dark grey streaks anywhere in the length of the extruded profile. The position of these streaks is not fixed and it appears anywhere. The pieces are 16 inch long.

If you can suggest a possible method to get rid of these we will be very grateful.

Thanking you,

Best regards,

metals - Jaipur, Rajasthan, India

A. Try with a 2% HF in the nitric acid bath. But you will need a lot of ventilation.

Ram. Gar- Livonia, Michigan

2005

A. Further to the last reply, try a 20 percent nitric solution without the HF -- a lot less nasty! Leave to soak for about one to two hours, then rinse and process as normal. The problem is the extrusion lubricants, which the nitric seems to remove, the time factor is a bit of an issue regarding production costs, but reworks are nil as far as I've found. This has worked well for me over the years. I hope this is of some use.

J Roberts- Bournemouth, Dorset, England

2005

2005

A. The streaks visible after anodizing mostly come from extrusion process. There are several causes:

1) The weld lines for hollow extrusions from porthole dies.

2) Lack of quality in the extrusion billet. Too thick segregation zone around the periphery of the billet, nonuniform homogenization or non-homogenized billet.

3) Oxides being extruded due to too much difference between the diameters of the billet and container hole.

4) Dirty inside surface of the container hole.

Chemical etching emphasizes visibility of such defects after anodising.

"Satin Brushing" prior to anodising can minimize risk of streaks.

"Satin Brushing" is done by a machine using sets of brushes made of stainless steel wire. This process also minimizes cost of caustic etching as you need less time (about 30-50% less) for the caustic etching.

aluminum extrusions & finishing - Istanbul, Turkey

|

One does not want to wire brush parts that are to be anodized, as the bristles can dislodge from the brush, and become embedded in the substrate, leaving pits, or bare areas after anodizing.  Marc Green anodizer - Boise, Idaho 2005 We have been wire brushing all aluminium extrusions we anodise to minimize the risk of white/gray streaks that may arise from extrusion process. The "satin brushing machine" we use a special machine dedicated for that purpose. The result is about 800 USTonne good satin anodised extrusions for architectural use. We have three machines (one with 3+3 sets of brushes, one with 4+4, one with 6+6 and just ordered the forth one with 6+6 brush sets. The SS wires that make the brushes are 0.15-0,40 mm thick. Regards, Timur Ulucakaluminum extrusions & finishing - Istanbul, Turkey 2006 Timur is probably ok in using SS brushes for his jobs, where small pits from embedded SS wouldn't be noticeable. But, as a rule, it's not a good idea, especially where good corrosion resistance is required.  Marc Green anodizer - Boise, Idaho 2006 |

Dear Chinmay,

Firstly I feel your chemical composition is on the higher limits of 6063 alloy (you said Si 0.5% & mg 0.7%).

Also you need to check the welding chamber depth of your dies; I suggest you to maintain the weld chamber depth around 22 mm.

Because your chemical composition is high, that's why your extrusion pressure is also higher than normal; and to overcome that problem your operator is pre-heating the billets more than normal temperature which surely leads to various surface defects.

You said that "Fe" content of your billets is 0.15% max which I doubt if you are not using primary grade billets. Still I think up to 0.25% of "Fe" content doesn't make much of difference if you can limit your billet composition: Si 0.40 to 0.44%, Mg 0.52 to 0.55%, with 'Fe' content 0.25% max.

Also check bearing length of your dies. Never over-design your dies thinking that the stronger you make a die that will give you more die life ... that's a myth. In fact you make a weaker die in turn. I am sure you will get better result if you try what I suggest.

- Pune, maharasthra, India

July 12, 2014

Stripes appearing in aluminum after anodizing

Q. In my factory, (not a job shop) we laser cut and punch several thicknesses of aluminum daily. We recently received a shipment of .090" 5052-H32 Aluminum heat tracked sheet with plastic Nitto sheet on one side. This is a standard material for us. Upon receiving our parts back from anodize, we can see very bold, uniform lines on the surface, both sides. The lines are blue tinted, and the base material has turned a gray color. We have seen this result from three different anodize vendors now, so it must be in the material. These lines show up on type II clear, and Type III Hard coat.

These parts have also been put through a timesaver on the back side, yet the stripes still appear. Has anyone seen this before? Does anyone know what is causing this?

Evan ParentManufacturing Engineer - Philadelphia, Pennsylvania, USA

January 14, 2019

White Streaks during anodizing of 6063 extruded Aluminium

Q. We are anodizing 6063 Aluminium Extrusions, Gloss level required is between 160-250. Our main problem is white streaks of .2 to 6 mm with length of 30 mm to 200 mm. About 50% of components get rejected. Process we follow is:

Degreasing, Rinse, Desmut in 24% Nitric, Rinse, Chem Bright with 65% Phosphoric +30 % LR Grade sulfuric with additive followed by by DM water Rinse Desmut again in Nitric 30 % DM water Rinse, soft Anodizing, DM Water Rinse two times, Cold sealing & Rinse, Hot sealing & Rinse. Air Blow and Hot air Dry.

Please suggest the solution. We get extrusions from Homogeneous Material which is 2 years old

Employee - Ludhiana, Punjab, INDIA

November 17, 2019

A. The white streaks are not caused by your anodizing but by the bright dip as your gloss requirement is very high, according to your bright dip solution formula provided, how long is your bright dip (>1.5 min)?

John Hu- Singapore

November 19, 2019

Q. Thanks, but it is 45 sec and temp is 95 to 105 °C

SK Dewan [returning]TECH AUTO PVT LIMITED - Ludhiana, Punjab, INDIA

November 24, 2019

Q. How to avoid thick streaks on 6063 extruded aluminium after brightening followed by Anodizing and Sealing?

TECH AUTO PVT LIMITED - Ludhiana, Punjab, INDIA

March 10, 2020

A. We have a lot of experience in bright dip, anodizing, and problems in 6063 alloy. These white streaks produced in the extrusion process can only disappear with a good combination of mechanical polishing, alkaline etching and a good glossy chemical process.

With a good chemical with additives, you can obtain a perfect shine and reduce the attack on the stripes.

Thank you.

- Cornella de Llobregat, Catalonia, Spain

April 27, 2020

September 7, 2021

Q. Lines appear on aluminium profiles

Dear Sirs

We have an aluminum profile production and anodizing line.

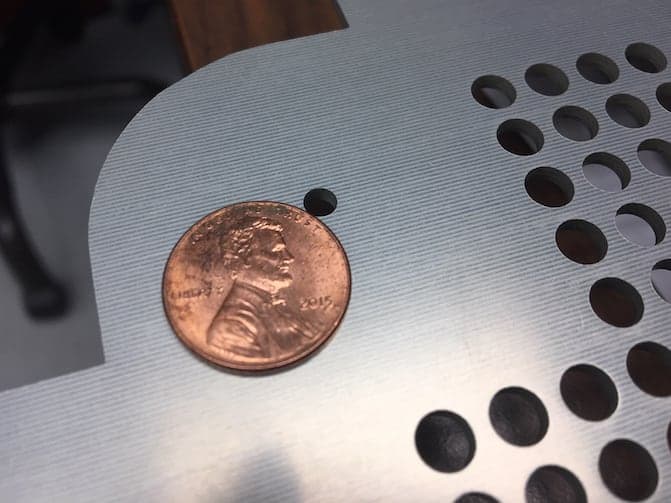

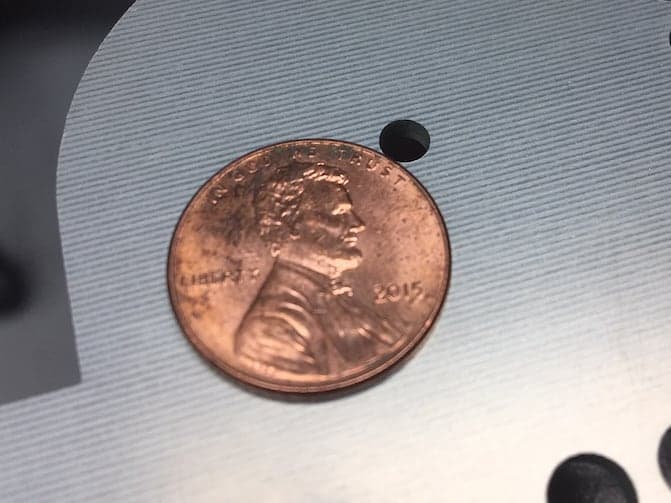

Recently, a problem has arisen in the profiles, which is more visible and determined after anodizing. (as you see in the pictures)

Could you please help and tell us what could be the cause ?

Yours Sincerely

Mousavi

- Istanbul istanbul

|

|

A. I recently managed a high production anodize line that had a very similar problem that was resulting in a reject rate of almost 40% of our production. We spent a small fortune trying to get the the root cause of the defect. We could never nail it down for certain within the time that I worked there. We investigated the extrusion dies, the lubricant used in the extrusion process, machining oil used during forming and hole-drilling operations, the buffing wheels, the compound that we used on the buffing wheel, the pressures and speed settings on the automated buffing machine. All of those were potential causes. The only thing that we able to eliminate for certain is that the issue was not created during any phase of the anodize process (it is only revealed as a result of the process as you had said). The problem definitely originates prior to anodizing even though it may be invisible on the pre-anodized part. That was my experience anyway.  Jon Barrows, MSF, EHSSC Kansas City September 16, 2021 A. Can you give us more details about this problem such as whats the defect rate/ happens only on these profiles/happens only etched profiles or polished profiles? Anodizing Supervisor - TURKEY Sakarya September 17, 2021 |

September 19, 2021

![]() Jon,

Jon,

Actually I agree with you. It happens before anodizing but still were unable to find the cause .

Thanks for your reply

Alaattin,

Thanks for your reply

Actually It happens before anodizing and gets visible after it.

We couldn't find the root problem.

- istanbul

A. Hadi, please respond to the questions which I asked you (also other contributors). You won't solve your problem if you don't. Thanks.

Alaattin TunaAnodizing Supervisor - TURKEY Sakarya

September 19, 2021

Q, A, or Comment on THIS thread -or- Start a NEW Thread