-----

Gold Recovery for Dummies?

Every environmental organization the world over is begging people who don't operate legitimate refineries not to try to recover the gold from old electronics; there are dozens of youtube videos from them explaining their many reasons. And it's not easy anyway. But we don't believe in censorship, so proceed at your own (and the planet's) risk...Q. About a year and a half ago I heard you could recover the gold out of computer parts. I am a little bit of a dumpster diver and have plenty of areas where I can get computer parts from, with a lot of gold left on them so I had to wait for about 8 months before finally I found some hydrochloric acid

⇦ on

Amazon [affil link]

.

My first attempt at recovering the gold was with vinegar

⇦in bulk on

eBay

or

Amazon [affil link] and salt mix for my electrolyte. the connectors are used as the anode. A sheet of copper approx. 6" x 3" is my cathode.

Power is a 12 V 2 A transformer.

My theory was that the acetic acid

⇦ on

eBay

or

Amazon [affil link] with added sodium chloride would dissolve the copper and nickel allowing it to plate onto the copper sheet while the gold would sink to the bottom.

The first attempt seemed to follow this theory; however, I did not notice any change in the thickness of my cathode. I figured this was due to how little copper plated out prior to the gold flaking off.

Repeating the process with the already saturated mix resulted in the mix taking on more of a milky white appearance. I am guessing this batch must have had a different metal in it somewhere but I am unsure what metal would cause such a reaction. the solution also seems to have particles of corroded copper (dark green) floating on it.

My questions are: 1. any theories on what would cause this? 2. why am I still not seeing the cathode getting thicker after almost 4 weeks of total run time?

Joshua Werthobbyist - crescent city, California

April 7, 2009

avail from eBay, AbeBooks, or Amazon

avail from eBay, AbeBooks, or Amazon

avail from eBay, AbeBooks, or Amazon

avail from eBay, AbeBooks, or Amazon

avail from eBay, AbeBooks, or Amazon

(as an Amazon Associate & eBay Partner, we earn from qualifying purchases)

! Dear readers! Please remember that internet forums are a gigantic "one-room schoolhouse" where you will see snippets on subjects which may be dangerous for you to dabble in if you are not trained in that field.

If Joshua is wearing proper protective gear and exercising reasonable caution, exactly what he has done may not be frightening. But general experimentation by mixing chemicals, electricity, heat, metals, etc., without being grounded in theory can produce extremely dangerous reactions.

His general proposition, that the acid and electricity will dissolve the copper and nickel, while the gold to sink to the bottom of his tank is in error. Gold recovery is a many step process, and unfortunately the belief that it can be recovered by simply dissolving the rest with vinegar, salt, and electricity isn't sound theory.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. I have a bunch of unopened bottles of precious metal glazes for ceramics.

Each says it has a net weight of 1 gram of gold or platinum.

Is there a way to recover the metal from these liquids?

thanks

hobbyist - SLC, Utah, USA

October 28, 2010

? Hi Cory,

Did you every find a way to extract the gold from the luster glazes?

Butch

artist - Wheeling, Illinois

September 27, 2024

Q. Sir, I am doing the scrap gold. I got a problem in gold recovery that is, actually I am using the method of collecting the gold coated material and adding the nitric acid and giving the heat. After boiling the acid, the gold layer appearing the top, collecting the gold layer, when I try to heat that gold it becomes nothing. All coated material gone. Any suggestion on this? One problem is nickel; a extract in this method I believe that nickel combines with gold; this my case.

Mulka Kalidasgold worker - Hyderabad, India

October 19, 2011

Q. Metal recovery from Philosophers Stone after conversion. I have been working on this process for some time, I am not 100% certain of the yield as yet as the conversion process is a little messy - basically what is left after extraction is a fine white powder a little like talc; then this is converted to metal form, it may be more beneficial to keep in the white powder form for the properties it contains. However, once converted back precious metals show and this has the higher market value at this point. Is it better to have someone else extract the metal elements from this powder rather than if I do this myself, are there any decent metal recovery companies I could send this to in Australia.

Andrew RuselleOpportunist - Australia

October 30, 2011

A. GOLD REFINING STEP BY STEP INSTRUCTIONS

For every ounce of scrap gold you are going to refine you will need a capacity of 300 milliliter container for the aqua regia solution.

1. Place impure gold to be dissolved into a glass or plastic container.

2a. Aqua regia - Mix one part nitric acid to 3 parts hydrochloric acid. OR

2b. To the container, add 30 milliliter of nitric acid for every ounce of metal.

To the container, add 120 ml of hydrochloric or muriatic acid for every ounce of metal in the container.

3. Allow impure gold to dissolve for an hour to overnight for complete dissolution.

4. Once all gold is dissolved, filter out any particles out of the acid solution containing the liquified gold into another glass container using a fine stainless strainer. The remaining particles should not be discarded as these may contain other precious metals!

5. The acid containing the dissolved gold will be an amber to emerald green color depending on the purity of the gold and should be clear (not murky or cloudy). If the acid solution containing the dissolved gold is murky, it may contain particles and should be re-filtered with a finer grade paper filter.

6. Slowly, add the water/urea (urine ) to the acid solution containing the dissolved gold. The acid solution containing the dissolved gold will foam with the addition of the water/urea (urine). Do not add the water/urea (urine) so quickly that the acid foams out of its container. When the acid solution containing the dissolved gold stops reacting to the addition of water/urea (urine), stop adding the water/urea (urine). You've just raised the pH of the acid from 0.1 To 1.0, killing the nitric acid but not the hydrochloric.

7. Add precipitant ( sodium bisulfite ) slowly in minute amounts to the acid solution containing the dissolved gold, immediately the acid solution containing the dissolved gold will change to a muddy brown appearance as brown particles of gold form in the solution. Occasionally agitate the solution with a glass stir rod, as the brown particles continue to form they will sink to the bottom of the container, this brown "mud" is, despite its appearance, pure gold.

8. Allow precipitant ( sodium bisulfite ) to fully draw out all the gold out of the solution, test for gold in the remaining solution, if it tests positive for gold, you may have to add more precipitant ( sodium bisulfite ).

9. To test the solution for remaining gold, first immerse the end of the stirring rod in the acid. Remove it and touch that end to a paper towel to make a wet spot. Put a drop of gold detection liquid on the wet spot on the paper towel. If any gold is still dissolved in the acid, the wet spot will turn a purple-black or a purple-brown. If you see this color change then give the precipitant more time to work and/or add more precipitant.

10. Now all the gold should be drawn out of the solution and the acid should now be a clear amber color with a brown mud settled at the bottom.

11. Using a fine paper filter, pour off the acid into another container allowing the mud to stay in the filter. The mud is pure gold.

12. When all the acid is poured off, return the mud to a container for rinsing, add tap water to the mud. Stir and let the mud settle. Using a fine paper filter, pour off the tap water into the container with the acid. Do not pour off any particles of brown. Repeat this rinsing 3-4 times or more.

13. After completing the final tap water rinse, rinse once again with aqua ammonia

⇦ on

eBay or

Amazon [affil link] ( %10 ammonia to %90 distilled water ) white vapors will appear. The aqua ammonia cleans impurities from the gold mud while, at the same time, it neutralizes any acid still clinging to the gold mud.

14. While in the fine paper filter, give the mud on last rinse, this time with distilled water until mud and filter is clean.

15. Take filter with clean gold mud and gently squeeze of any excess water and place filer with mud into crucible for melting.

16. Once melted, the gold will again take on the appearance of metal. If you've followed the instructions carefully and used filters, the gold will be 999.5 % Pure with virtually no losses.

17. Platinum- If you had platinum in your gold, it will not dissolve, to any appreciable degree, in the room temperature aqua regia. It will be left behind when you pour off the aqua regia, prior to precipitation. To insure high purity of the platinum, you will need to re-refine this material. Put this material in a fresh aqua regia bath. This time, however, heat the acid to simmering. Continue heating until all the platinum is dissolved (that may take 1-2 hours). When completely dissolved at 1 ounce of ammonium chloride for every ounce of dissolved platinum. The platinum will precipitate as a red mud. If you want to leave the iridium in the platinum, then wait for it to precipitate before recovering the platinum. Iridium will precipitate as a blue-black mud after the platinum precipitates. Platinum group metals will also show up on the stannous chloride test. Platinum turns red, palladium Palladium turns orange and iridium turn blue-black.

- ELGIN TEXAS USA

January 7, 2012

A. Philosophers stone? Alchemy? When using nitric acid to remove base metals in gold recovery it is very easy to misplace your gold. On electronics that use gold for shielding (such as RF shielding) the gold can be very thin and instead of coming off in foils will separate into finely divided particles and will get lost in trash. Another cause for missing gold recovered this way is bad work habits. Dirty glass that has been cross contaminated will hold chemicals that can't be seen. Did you use the glassware for any solution that contained a HCl acid solution? If so, remember that you can't rinse acids from materials. If you use a container for a HCl solution and then rinse well, and then use it for a nitric acid solution a weak aqua regia will form and dissolve values. A small amount of HCl will make quite a bit of AR solution. As far as the philosophers stone, the only one I can think of is the one in the Harry Potter stories. Values that have been precipitated have distinct colors and as far as white powder goes, metal salts can be white if crushed finely enough. If you would like some help, put the witchcraft aside and let me know what you did to get what you have and I will try to give some advise on what it is and what can be done with it.

Jeff Massey- Decatur, Alabama, USA

Q. What chemicals are used to decay gold from ore so that you can extract 90-100%? I would like to extract 100% of gold from its ore -- what chemical can be used to insure all the gold within an ore is extracted?

Abdulkarim A.- Cottbus, Germany

February 5, 2012

Q. My first couple of batches with AR (aqua regia) worked out great and got really clean gold out of it after melting. I tried Sub Zero the last few times and it has left me a mess! I know there is gold in it I should have about a half oz somewhere in my buckets. After dropping the gold with smb it turns brown and eventually developed but unlike the first few batches with nitric acid it is reacting like pd during the wash and is nearly impossible to pour off. After boiling in distilled water to help bond it together through out the many washes it is turning black and has edges on it and melts to a dark silver lead color. What is going on? I have read that too much smb will drop lead and other metals with the gold but it is brown at first and is super buoyant. Is this large brown sponge good? Should I just wait it out till it settles and not boil it? I have distilled some of this brown sponge but by the time it dries it is not brown anymore! I am very confused and frustrated. Also with the nitric I didn't get the return I was expecting but at least I got some gold out of it! Will the aluminum foil drop the gold and all if I end up having to start completely over? I tried another batch of AR with this black substance powder and still no luck! Is it the sub zero or just a mistake on my part? Please if anyone can help! I thought it would be easy after the first couple batches but now have way too much money invested to not be getting a return.

Thanks

James

- New Mexico, USA

March 12, 2012

Q. I have removed gold connectors and other gold pieces. I need to know the simplest way to smelt it and where I can purchase the products. Can you please help me?

BONNIE STARRgold smelter - Dyer, Indiana

March 30, 2012

A. Chemical extraction of precious metals from ore is a very long and tedious process. First, the ore has to be roasted to a red hot temperature and held there for 20-30 minutes; this reduces the sulfides to sulfur dioxide and the organic carbons to carbon dioxide. Next, you need to mill the material to about 200 mesh. The first chemical leach will need to be ferric chloride ⇦ on eBay or Amazon [affil link] ; this will remove iron; heating the material speeds this process up. After the solution turns black, decant and rinse well several times with water. Next, add diluted sulfuric acid and stir; heating the material speeds this process; this removes any iron oxides left from the ferric chloride wash. Rinse with water with several cycles. Now you are left with a good material fit for leaching with aqua regia. There are a couple of other leaches but they are far more dangerous than the one I described.

Jeff Massey- Decatur, Alabama

Q. Certain easy steps to refine gold from old cpu using Nitric acid or AR?

Hello. I started my refining process since two weeks before, I am stuck up in the nitric acid process. I am able to see the golden foils in the bottom of the glass jar along with other metals, which I am not able to separate. Kindly help in this step.

Syed Nooruddin- Bangalore, Karnataka, India

June 23, 2012

Q. Hi I recycle computers. I want to know is there a way to get gold without dangerous chemicals? If I could learn without danger to my life?

Larry lanecrap - Illinois usa

October 24, 2012

Q. I am an avid treasure hunter and I find lots of gold plated, gold filled, and silver plated items yearly. I know they do not have a tremendous amount of precious metal on these items yet if I could recover it inexpensively it would eventually add up. I also have several pounds of gold plated electronic scrap I would like to recover the gold from. So my question is simply what is the most cost effective, safest and simplest method of doing this. I have an extensive background in both OSHA and EPA regs. and have spent many hours in chemical environments. Is this a viable idea / hobby that will allow me to make a few bucks without investing a fortune with no hopes of a return?

Ralph Waldrop- Seymour, Tennessee, USA

February 3, 2013

Q. I want to use the electrolysis method -- reverse plating!

I have gold covered items mainly leaf over paper. I also have computer parts.

I would just like to be able to actually use a glass fish bowl type - 4 gallon capacity - what type solution would help the transfer of the gold from the host to the anode?

I would prefer no hazardous solution - I also have already made arrangements for a scrap yard to recycle left over scrap materials.

This is a hobby type endeavor. I don't want to do the eBay thing. Just want to see if I can do this.

What solution do I need?

Thanks

- Lancaster, New York, USA

February 14, 2013

A. Hi Rich. I don't know what you mean by "the eBay thing" ... buying gold recovery equipment [adv: that stuff on

eBay], buying gold-bearing scrap [adv: gold scrap on

eBay], selling scrap to eBay?

If you feel that you know enough to safely experiment, no one can stop you. But things that seem dirt simple often aren't really quite that simple :-)

When you are doing electroplating, you're not moving tiny bits of gold metal from the anode to the cathode (that's not possible), what you are doing is dissolving the gold into the solution as a gold salt, moving the gold ions in the salt from anode to cathode, then oxidizing the gold salt back to gold metal. So to create even the poorest gold plating deposit for subsequent refining requires that you use a solution which is capable of dissolving the gold as a salt and keeping it in solution. That is hard to do without a "hazardous solution", usually based on deadly cyanide -- it's not something you're likely to do with table salt.

which explains what can be achieved by de-plating, and on which substrates. Strong sulfuric acid, S.G. 1.65, with some sort of cooling to make sure it doesn't go above 100 °F should work. But the gold does not plate out, rather it precipitates as a mud, probably requiring further refining to be saleable.

Luck & Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Hi. I am trying to get gold from cell phones. There is lots there and I am grinding the gold off, then using sulfuric acid. It is getting most of the stuff to dissolve the silica but the copper is still there? I have seen your posts on different ways to extract gold and lots of techno-babble. I am dyslexic but not dumb. Need to know safe and productive way to retrieve gold. There are lots of phones out there and money to be made. Any help would be good, thank you.

Logan Yeates- Mission, BC, Canada

June 24, 2013

A. Hi Logan. Do you know the thickness of the gold plating, so you have some idea of how much gold is there? You'll never know whether your process is efficient or you are just pouring 90% of the gold down the drain until you start with that. Good luck.

This page includes the step-by-step instruction you seek (for example, the 17 steps generously offered by C. Wilford), please don't dismiss them as "techno-babble". People have told you there is no safe way for someone with no chemistry knowledge and training to dabble around in complex chemical recovery operations involving cyanide and aqua regia, so there is no "safe and productive way". Sorry.

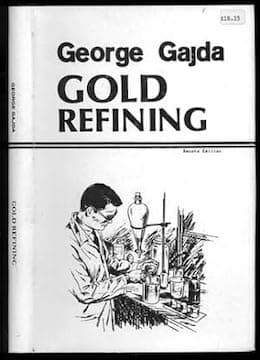

Complex chemistry can't be made simple. If you choose to not try to learn the relevant chemistry it will forever remain "techo-babble". You have 3 choices: stop, live very dangerously, or commit yourself to studying & learning the subject. George Gajda's little book "Gold Refining" [on

eBay ,

Amazon,

AbeBooks affil links]

covers the whole subject and is very understandable.

If you want to just try to scrape the gold off with an Exacto knife

⇦ on

eBay

or

Amazon [affil link] be 100% sure to never do it without wearing good, real, safety glasses

⇦ on

eBay

or

Amazon [affil link] . A shard of razor sharp steel breaking off and flying into your eye is a possibility.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. I have a question. How to get the gold out of the liquid after using Muriatic acid and Peroxide? It is green from copper. OK. But it has a lot of gold in that liquid.

L. Kiss- Tucson, Arizona

October 14, 2013

A. Hi L. Please try to phrase your question in terms of the step-by-step instructions that C. Wilford posted, or an alternate list of instructions. You're certainly welcome to ask for clarification of a step that you don't quite understand, but it isn't reasonable to ask how to simply skip step 6, 7, 8, 9, 10, 11, 12, 13, 14, and 15, and jump from step 5 to step 16 :-)

Luck & Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Hi friends!

There is no e-waste recycling company in our country. I have the question of how to recover gold from discarded cell phones. I need to learn a complete process to recover gold and other precious metal from them. Please somebody help me.

Himel Jahan

- Dhaka, Dk, Bangladesh

December 5, 2013

Q. My uncle is also getting into this. Anybody have ideas to extract gold from rocks and circuit boards? Is there any way to do this like smelting? Any chemicals or etc.? Please post if so.

Cory Mill- Belton, North Carolina, US

December 21, 2013

Recovery of gold from cyanide solutions that have sodium chloride?

Q. Good afternoon. I wonder if anyone knows how to recover gold from cyanide solutions when the solution containing gold has also added sodium chloride?

What happened is, trying to recover gold from PGC salt (potassium cyanide and gold), which was dissolved in water and carried electrolysis but by mistake addition of sodium chloride which changed the color of the solution to a pale yellow, then added potassium cyanide to improve conductivity but did not recover anything in electrolysis, and nothing that I could form compounds with sodium chloride. I think that when you add the sodium chloride of the gold PGC AuCl4 step.

- Bogota, Colombia

January 21, 2014

(you are on the 1st page of the thread) Next page >

Q, A, or Comment on THIS thread -or- Start a NEW Thread