-----

Shafting and bushing/bearing issues

Q. We recently experienced a problem with our Tea weighing system. There was tea leakage from the weighers, whereby they were overhauled. Previously we were using normal Mild Steel shafts with phosphorus Bronze bushes. During overhaul, however these shafts were replaced with Chrome plated MS shafts.

When the machines were put back into operation most of these shafts seized. Upon analysis it was revealed that the chrome plated surface fused to the bronze bush upon heating - and restricted its movement.

My question is whether this was a correct hypothesis ?

Should this have happened?

How could it have been prevented ? Increasing lubrication, changing material etc. ?

Khawaja Abdullah- Manufacturing - Karachi, Sindh, Pakistan

2004

A. Something about that doesn't sound right. Were the clearances the same as before?

Jeffrey Holmes, CEF

Spartanburg, South Carolina

2004

A. The hypothesis is not only right, but I'm afraid to say is obvious. If the bronze was welded to the chromed shaft it had to be due to temperature, what else? Now, the situation sounds right to me. A chromed surface does not "wet" well with oil. For that reason, chromed surfaces requiring good lubrication must not be highly polished. As a matter of fact, they have to be provided with adequate oil "pockets" by leaving the ground finish a bit rough or applying porous chrome, such as the one used in engine piston rings.

Guillermo MarrufoMonterrey, NL, Mexico

2004

Q. I am having bushing vibration issues while using a 50C hardened 440C stainless shaft (~20 microinch finish) with an SAE spec graphite impregnated bronze bushing. The 5/8" ID bushing is running at a .0005" - .001" diametral clearance. The bearing is stationary while the shaft spins. The bushing supports a 1.5 lb hanging mass. It appears that the bushing/mass system is vibrating while the shaft spins, creating the appearance of high friction and making noise. Has anyone had a similar problem? What can be done to fix it (different shaft material, plating, or clearance?). Thanks in advance!

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

Richardson

- Palo Alto, California, USA

March 20, 2012

A. Assuming the shaft is straight, it sounds like a harmonic vibration. Changing almost anything will stop it:

Shorter, longer, lighter or heavier shaft. More rigid bearing mount. Less rigid bearing mount. Moving the bearing to a different place on the shaft. Longer or shorter bearing length. Lighter or heavier load on the bearing. Change in rotational speed.

Try whatever is easiest, change one thing by 20% and see if it goes away.

Jeffrey Holmes, CEF

Spartanburg, South Carolina

April 3, 2012

Q. I have a very old Hayter lawnmower with a rear drum; the mild steel shaft that runs the drum has a phosphor bronze bush at either end; one end has worn the shaft considerably. If I replace the bushes would it be ok to braze the shaft where the bushes run to reduce the slack or would this be really silly? The shaft is not fast turning and takes little force but is 40 years old ... or would it be better to weld shaft ? I have means to grind shaft back to circular after.

Dave Walker- United Kingdom

March 16, 2018

A. Hi Dave. Bronze bushings run best on harder material, so weld it if you need 40 more years out of it. But brazing will probably hold for a decade :-)

But if it's just a plain shaft it seems easier to put in a replacement length of shafting.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for quick help

or longer-term assistance.

March 2018

March 17, 2018

![]() Thanks for getting back so quick Ted,

Thanks for getting back so quick Ted,

Its my Grandfathers Hayter 56 mower that has been with him since new; he's now 84 years old. It's more a case of getting it back to a sensible state of repair so it actually drives itself. She's a fully aluminium body with a triple roller on the rear, one driven and the other 2 are on special one way bearings (like a bicycle rear cog).

The shaft has multiple key ways, etc., so would be a nightmare to source or remake -- that's why I asked :)

I think he's been pushing it for the last few years (though he won't admit it), so a quick repair with braze will I'm sure be sufficient for the few years use that it needs to be capable of doing.

- United Kingdom

Q. Hello,

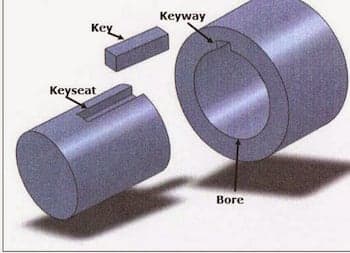

I am looking to support a number 3/4" steel keyed shafts which all need to rotate. I am considering using Bronze bushing but was wondering if the keyway would catch/bind and cause any issues?

I could machine a collar to fit over the shaft but would rather avoid the extra work if anyone has tried a comparable bushing set up or has an opinion I'd love to hear it!

Thanks guys,

Greg

- Victoria, BC, Canada

February 21, 2019

A. Hi Greg. I think you'll need to send a sketch for people to understand you.

A properly deburred keyway probably wouldn't harm a bronze bushing unless the loads were so great that the whole idea was questionable anyway :-)

But the thing is, where there's a keyway there's supposed to be a key, and the key can tear up the bushing. A key is not supposed to be shorter than the keyway, and it's very likely to "walk" if it is. Running a keyway all the way to the end of a shaft makes it easier to machine but less secure.

A keyed taperlock bushing is the most secure way to hold wheels & gears & sprockets & couplings to a shaft. If the loading is light, a non-keyed taperlock bushing can work.

Maybe you're saying you want bushings on the end of shafts that have unused keyways on their ends? Adding a machined collar around the shaft, and using the O.D. of the collar as the bearing surface (if I'm understanding you) would increase the both the speed and distance traveled at the sliding surface between steel and bronze, and thus sounds like a bad idea. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for quick help

or longer-term assistance.

February 2019

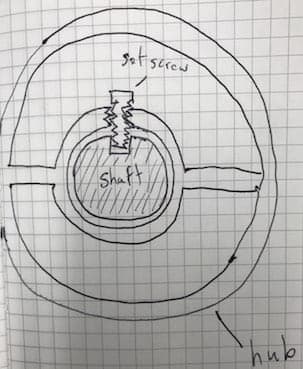

Q. Hi Ted,

thanks so much for getting back to me, not sure how to post a sketch - do I have to link to an external website?

That's good to know about a deburred keyway - I'll be sure to use some sandpaper of increasing grits to get the contact area smooth.

The key shouldn't be a problem - I was planning to just fix the roller to the shaft's keyway using set screws, it is a low torque low speed application.

The reason I'm asking about bronze bushings is I am hoping to have the shafts be put on and off quickly. I'm planning on the bushing in contact with the bottom 180 degrees of the shaft and open on the top surface to facilitate a quick change.

- Victoria, BC, Canada

February 25, 2019

February 2019

A. Hi again Greg. Although I had a fair amount of experience with bronze bushings in my career, I don't actually have any personal experience with the 180° half bushings that you describe, although they sound okay.

Unfortunately, I do have some experience with keys 'walking' when they are shorter than the keyway and only held in place by a set screw in the key and one at 90° into the shaft. A key that is shorter than the keyway is quite possibly a design flaw that you really should try to fix. The ideal is probably rounded-end keyways with rounded-end keys (feather keys).

Please be sure to carefully think through whether any mishap or malfunction could overcome gravity and dangerously lift the shaft off those half bearings.

Pics and sketches can be e-mailed to

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for quick help

or longer-term assistance.

Thanks Ted,

That is good to know about keyways - I am not experienced using them. I think I am using the set screw in a different way than you are describing.

Best Regards,

Greg

- Victoria, BC, Canada

(pic courtesy of couplinganswers.com)

(pic courtesy of couplinganswers.com)

A. Hi again Greg. Things can be held in place on shafts with setscrews in this fashion if there is no loading. For example if you have wheels on an axle and the axle is on bearings so the wheels and shaft turn together. That may be the situation you are describing with your roller.

But you can't use setscrews to transmit torque for a number of reasons, including that they are made of very brittle hardened steel which can snap. If you need to transmit torque from a shaft to a wheel or from a gear to a shaft, as a minimum the connection must be "keyed".

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for quick help

or longer-term assistance.

March 2019

![]() Thanks Ted,

Thanks Ted,

Appreciate your advice - will look to redesign and avoid this issue.

- Victoria, BC, Canada

March 4, 2019

Q. I am running a botanical extraction process which requires a centrifuge to separate out waxes. The miscella is chilled and fed into the centrifuge. The equipment was bought new and plumbed to a skid by a separate vendor. We made several attempts to prime the centrifuge before we figured out the vendor plumbed the fluid inlet wrong. Once we replumbed priming was easy.

After an hour of operation the shaft started wobbling. Upon disassembly it was discovered there was significant wear on the stainless shaft and the aluminized bronze bushing. We had the shaft turned down (finish was terrible) and a new oversized bushing made. Upon reassembly When the cold methanol was introduced the bushing seized to the shaft.

First guess is the clearance was too small. Perhaps the bushing was not the material advertised. The finish on both the shaft and the bushing was very poor.

Any ideas how to fab this correctly?

- Nairobi, Kenya

June 9, 2020

![]() Upon further exploration the fabricated new bushing was not aluminized bronze. Also someone read the manual and discovered the bushing should be greased every 30 minutes. They hadn't greased it for days. :-(

Upon further exploration the fabricated new bushing was not aluminized bronze. Also someone read the manual and discovered the bushing should be greased every 30 minutes. They hadn't greased it for days. :-(

- Nairobi

June 10, 2020

Q, A, or Comment on THIS thread -or- Start a NEW Thread