-----

Lacquering aluminum- can it be done?

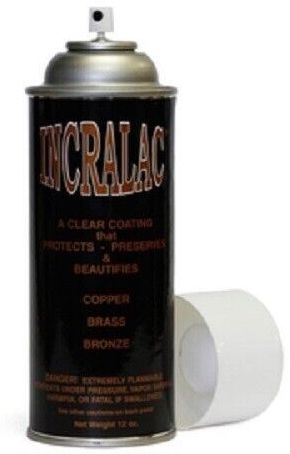

I work for a small engineering firm and I am currently investigating different possibilities for providing a shiny finish on marine application aluminum extrusions and wondered if it is possible to lacquer (varnish) aluminum. I have read that Incralac ⇦ on eBay or Amazon [affil link] works but before I muck it up, I would love some advice! I have considered anodizing and am trying to think of a more novel solution before I try tests.

Many thanks.

Helen Thorneycroft- Southampton, Hampshire, UK

2004

2004

Dear Helen

There are several possibilities:

1. mechanical polishing and then lacquer (this is not the best solution)

2. mechanical polishing and then anodising max. 5 micron (this is not a very corrosion resistance solution, if the parts are placed outside)

3. using an alloy for bright anodising, chemical polishing and then 20 micron (best solution for outside use)

Anne

Anne Deacon Juhl

- - Trustrup Denmark

You can anodize(30 micron) and then lacquer it(without sealing). Incralac ⇦ on eBay or Amazon [affil link] is good, but probably you can try to find something better.

Goran Budija- Cerovski vrh Croatia

2004

June 11, 2010

The best way of preparing aluminium for a marine environment is to anodise(6-7 microns) and then coat it

with an anodic electropaint. Do not seal the aluminium as it

will then not be conductive and anyway the lacquer becomes the sealer. This system is excellent, especially for filiform corrosion resistance.

- Birmingham, United Kingdom

Q, A, or Comment on THIS thread -or- Start a NEW Thread