-----

Strange hull cell results for nickel chloride plating bath

Quickstart:

For successful operation, monitoring, and testing of nickel chloride plating baths (or any plating bath), a Hull Cell

⇦ huh?

is a nearly indispensable tool.

Q. We are running a plating shop and we buy nickel sulphate & nickel chloride. We try taking hull cell panel of 300 gm/lit nickel chloride at 0.1 OR 0.2 amp , 01 volt with air agitation

⇦ huh? for 10 minutes without adding anything else, we get hull cell panel with dark grey/black deposits at high current areas, whereas low current areas are clear with no blackness. Is our procedure correct & is our nickel chloride okay?.We have also checked about impurities by atomic absorption spectrophotometer ⇨

All impurities are well within range.

Please advise

plating shop - LUDHIANA, Punjab, India

2004

A. Please check the pH of the nickel chloride solution. Maybe excess acid in the nickel chloride due to poor quality may cause this problem. Also use some boric acid along with nickel chloride. Normal ph of 5% nickel chloride solution is above 3.5.

P. Gurumoorthi

electroplating process chemicals - Chennai, Tamilnadu, India

A. You may try this formulation:

Nickel sulphate (NiSO4.6H2O) 240-300 g/l

Nickel Chloride ( NiCL2.6H2O) 40-60 g/l

Boric Acid (H3BO3) 25-40 g/l

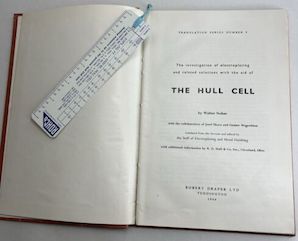

When performing Hull Cell test ⇨

keep in mind that this test will tell you the plating range, meaning, if the panel has a good, clean, semi-bright to bright deposit at 0 to 50 ASF, then you have to use this current density in the actual plating of parts. You have to check what current density will give you the desired cathode efficiency.

- Hawthorne, California, USA

A. THE PURPOSE I DO NOT KNOW, BUT I CAN ASSURE YOU AT 1 VOLT AND 0.3 TO O.4 AMP. THERE SHOULD BE NO BURNING IN H.C.D. AREA, TEMP 35 TO 60 °C. HCD BURNING: CHECK pH OF SOLUTION, RECTIFIER, NICKEL CHLORIDE. GET IT ANALYSED FROM A REPUTED LAB., CHECK NITRATE, CATHODE SIZE, ANODE SIZE.

Ajay Raina

Ludhiana, Punjab, India

A. The usual amperage for Hull cell testing is 1 amp to 2 amps, not 0.1 and 0.2amps. Little or no deposition from a nickel chloride solution will take place at such low amperages.

Don Baudrand

Consultant - Poulsbo, Washington

(Don is co-author of "Plating on Plastics" [on Amazon or AbeBooks affil links]

and "Plating ABS Plastics" [on Amazon or eBay or AbeBooks affil links])

A. Hello...

Sorry, but I don't understand your intention. I think your intention just to test your nickel chloride ok or not? But you wouldn't understand with this way. I think, you must prepare Mr.Molina's formula. Also your Hull-Cell panel must be very very clean (hot degreasing and electrocleaning). And you must set up rectifier 1 Amp 10 min. (for rack); 0,5 amp 5 min.(for barrel). You can see your panel normal without any blackness or something. If you see some wrong appearance then you must different. But you must try first this. And you mustn't set up your rectifier 0,1 or 0,2 like this small amperage. Because then results become all wrong.

Good Luck.

- Turkey

2004

A. The usual current for Hull Cell is 1 to 2 Ampere so the current that you use is not correct. Also check the solution pH. If it is high then the acidity of bath is too high so the coating is resolve in solution.

Best Regards

- Tehran

2006

Q, A, or Comment on THIS thread -or- Start a NEW Thread