-----

Can't get consistent finish on Forged Products

I am a professional blacksmith who makes a line of forged iron products. I have been in the business by word of mouth for about twenty years but recently lost my day job, which has put me into it as my primary means of income. I have experimented with various types of finishes for steel and am looking to apply a consistent dark grey or black finish. I have read some of the letters on this site but need some advice on finish and application.

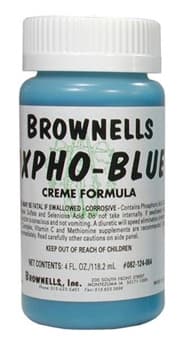

I am using A36 hot rolled or 1018 cold rolled stock. I typically forge the material and either wire brush or tumble in blasting sand to remove loose scale but neither process is 100% reliable and often leaves spots that leave an imperfection on the surface or chips off later. I have recently experimented with muriatic acid to clean the steel and it seems to do a good job but I'm not sure that I'm killing the etch and am afraid it will begin rusting at some point. After the etch, I wash the item in cold water and dip in cold blue solution (Oxpho from Brownell's Gunsmith Supplies) ⇨

The blue usually takes but occasionally leaves spots. I then rinse in cold water and wipe dry then lightly abrade the item with fine 00 steel wool

⇦ on

eBay or

Amazon [affil link] , which removes the dullness of the bluing oxide, then final coat with a semi-gloss urethane. This usually gives a pleasing color reminiscent of an older gun barrel that has had some service.

My problems are dealing with the hazardous chemicals and the inconsistency of the finish plus the excessive labor required. I am in a rural area and do not have any close neighbors but I also do not want to create any problems. I have also considered building a hot bluing setup like the type used by gunsmiths. I would like to obtain a dark consistent finish with no scale left on the item - any recommendations are appreciated. Hollis W

Professional Blacksmith - New Braunfels, Texas

2004

Q, A, or Comment on THIS thread -or- Start a NEW Thread