-----

What Metals Rust the Fastest (Steel, Copper, Bronze)

< Prev. page (You're on the last page of this topic)

Hi, I'm Charlotte and for my science project I need help. Why can Iron rust but not Bronze and why does Bronze last for so long. Thanks so much! P.S could you help me soon because its due in 2 days!

Charlotte Faeste- Sydney Australia

March 13, 2015

Hi Charlotte. One reason this page is so darned long is because we've answered that question of why bronze can't rust again and again :-) ...

Although you might not know how long it will take for a piece of old chicken to become rotting chicken, you do know how long it will take for an old tomato to become rotting chicken: never ever, because tomatoes aren't chicken.

Rust is rotted iron. How long will it take for bronze (which is a different metal than iron) to become rust (rotted iron): never ever. Bronze and other metals can rot, corrode, tarnish, whatever -- but they can never rust because rust is defined as oxides of iron, the corrosion product of iron, rotting iron.

Bronze lasts a long time because when it begins to corrode, the oxides of bronze tend to be adherent and solid, so you get a thin coating of corroded bronze on the rest of the bronze that keeps air and water from getting to the underlying bronze and continuing the corrosion. That is, the corrosion products tend to seal away the bronze from the environment.

The corrosion products of iron, though, are non-adherent, loose, fluffy, and hydroscopic (suck up water, keeping the iron wet) so the iron stays in contact with the air and water and just keeps corroding. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Hello, My name is Angel, I am 16 almost 17, and I am doing a coin project for my chemistry in the Community class, I am making a coin and I need to figure out when and how gold, silver, platinum, copper and zinc corrode or tarnish, and how long they last. My coin is coated with 10% of each of the metals and 60% zinc for the center, its as heavy as holding 21 pennies, and the thickness is 3.00 mm, and mass 52.5 g, and diameter is 5 cm, can you please help me? Thank you if you can~ =^vv^=

Angel H [surname deleted for privacy by Editor]- Wautoma, Wisconsin, USA

April 9, 2015

"But I was a mere lad of sixteen

-- I've aged a year since then."

A. Hi Angel. Thank you for reminding an old man of a favorite song from way

back when ... .

Gold and platinum don't corrode -- they'll last almost forever. How long other metals last depends on their environment.

I don't understand what you are trying to ask with your percentages and dimensions. What is the question?

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

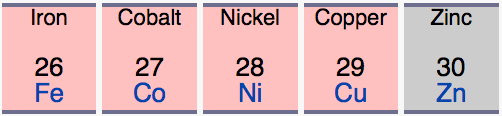

Q. Do metals rust faster due to their number of protons?

Jacob T [surname deleted for privacy by Editor]- Madison, Wisconsin, United States of America

November 13, 2015

Hi Jacob. No, I don't see such a pattern. Here for example are the elements with 26 through 30 protons .

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

January 2016

Q. My science fair project is also on which metal will rust fastest. I used steel, iron, and bronze as my metals. The steel rusted fastest but I don't know how to capture the data. How do I capture the data for tables, charts, and graphs?

Noah G [surname deleted for privacy by Editor]- Washington, DC

December 5, 2015

A. Hi Noah. When we are trying to express something in a foreign language which we are not yet fluent in, we usually have to think it all through in English, and then try translating it a word at a time. Tables and graphs are languages used to convey information, that you're not yet fluent in, so you'll probably need to express your results in words first.

"The steel rusted fastest" isn't enough info/data to bother trying to put into a table or graph. Tell us in words what data you have accumulated and we can help you build a table or graph that captures it. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

January 2016

Q. Hi, my name is Sofia and I am 11, in Gr. 5. For our science fair project, at first, we thought of finding out which from 3 nails would rust the fastest in water. We didn't think of what metals we'd use for our nails when we were going to try to but, my teacher thought of another project for us, it was to test out if stress on metals by pressure does really make them rust (because he heard it does) and then, how he said we could test that was by dropping a hammer from a high height to a metal can and observing if it rusts.

But then, when I researched about the project he thought of, the kind of corrosion he was talking about was Stress Corrosion Cracking and I found out about it that when metals experience it, it doesn't rust and just gets cracks so I thought, "Okay, when hitting the metal can, after, we'll just observe for cracks instead then but then later on, I found out it takes very long for the cracks to become big enough and noticeable and that when they are small, it is invisible and can only be detected by this process called mdi or something and that process.

I really think our group can't do it, it requires super expensive stuff and then I also found out that hitting does not stress out metals but these confusing and unsafe liquids do so, the project teacher thought of was a super no-no. So, I just thought we can go back to our old project but it's like so common and typical so I just thought of 2 more experiments that might be better:

- Finding out which is the best way to prevent rust from ways I found on the internet and

- for 2nd one I thought of but this time on removing rust.

Please help me choose the best one from the 2 new project ideas I thought of and the old idea. Or please, suggest another project! Thank you, I am so sorry for the long post.

Sofia P [surname deleted for privacy by Editor]- Pasig City, Philippines

January 13, 2016

A. Hi Sofia. Unless you find it uninteresting, I'd go back to the original and please the teacher. Stresses not only cause stress corrosion cracking, they also cause galvanic "hot spots" -- areas that will rust or corrode in water or acid faster than the rest of the metal ... As an aside, if you connect zinc and steel and put them in saltwater or a mild acid like vinegar ⇦in bulk on eBay or Amazon [affil link] or lemon juice, the zinc will corrode to prevent the steel from corroding. If you put some connected steel and copper into the saltwater or vinegar, the steel will corrode to protect the copper. Now back to your project ...

If you highly stress a metal, the area in tension will sacrificially corrode to protect the rest of the metal. You might try putting one piece of stressed metal into a jar of salt water, another into a jar of vinegar, another into a jar of lemon juice. Then take a piece of unstressed metal and put it in saltwater, another in vinegar, another is lemon juice and see if whacking the heck out of it did indeed make galvanic hot spots that led to quicker corrosion. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

January 2016

Q. Hi. I was wondering what is the name for copper corrosion and silver corrosion.

DEBRA A [surname deleted for privacy by Editor]- Toronto, Ontario, Canada

March 27, 2016

A. Hi Debra. I don't think they have any really special names. "Tarnish" or "corrosion" is just about it. The reason that iron/steel corrosion has the special name "rust" is probably just that there is much more iron and steel in the world than copper and silver, and corrosion of iron and steel is a much bigger problem for at least two big reasons:

1. Corrosion of steel is usually faster and more severe that the corrosion of other metals largely because the corrosion product is dusty and flaky and hydroscopic (water absorbing) and doesn't slow the corrosion (the presences of rust leads to more rust), whereas the corrosion products of copper and silver may be tenacious and slow down the ongoing corrosion.

2. Steel is often used for structural purposes. A bridge or building or ship can collapse if there is too much rust.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

March 2016

A. Debra,

Copper oxide corrosion on copper and copper alloys is sometimes known as "patina".

I don't believe that silver tarnish goes by any other names, but instead I'll give you a bit of trivia. Contrary to most other forms of corrosion, silver tarnish is NOT silver oxide! It is in fact silver sulfide. (One of my professors back in grad school said his family's silver never tarnished until a factory was built in town.)

Bonus trivia! Rather than removing silver tarnish abrasively with polish, it is easier to remove it electrochemically using a hot water bath with some electrolyte (usually baking soda) mixed in, and some aluminum!

Ray Kremer

Stellar Solutions, Inc.

McHenry, Illinois

March 29, 2016

Q. I have enjoyed reading this thread of many years! I've learned from it and have a few questions. I designed a stainless steel bottle stopper for artists to put their artistic creations on the top. It started 10 years ago (accidental business!) and I have learned a lot about the grades and chemical percentages in stainless steel.

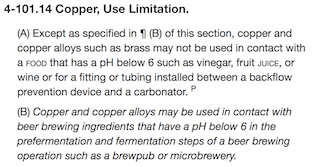

A customer requested brass stoppers, a metallurgist for a local company said he saw no reason why I couldn't use brass as there are brass wine goblets. My stoppers are used in olive oil bottles, wine, liquor, bath oil and herbal vinegar bottles.

I know brass will tarnish but that's a sort of even and slow process but, before I put brass stoppers in my inventory, can anyone tell me if it will rust or get ugly spots or???

Thank you

Niles Bottle Stoppers - Newville, Pennsylvania

May 24, 2016

A. Hi Ruth. Per www.fda.gov/Food/GuidanceRegulation/RetailFoodProtection/FoodCode/ucm188064.htm

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

May 2016

A. Actually, you don't have to make the stoppers out of brass. Suggest you make them out of stainless steel, and apply a PVD coating that looks just like brass. Of course, it won't scratch as easily as brass (or stainless steel), and won't tarnish... One other issue to consider is lead. Most brass alloys contain lead -- it makes them more machinable. In the faucet business the lead content is severely limited in waterways (pipes, spouts, shower heads, and the like).

Jim Treglio - scwineryreview.com

PVD Consultant & Wine Lover

San Diego, California

May 25, 2016

Q. Which will corrode first, carbon steel or alloy steel?

kalyan vignesh- Mumbai, Maharastra, India

June 24, 2016

A. Hi kalyan. "Carbon steel" means plain steel. "Alloy steel" means steel with other metals alloyed into it like nickel and chromium. If there is a substantial amount of these other metals, the corrosion resistance is improved significantly -- both because the alloy is less prone to corrosion and because the corrosion products that do form will tend to be more impervious and less dusty than regular rust. In such cases the alloy steel is often called stainless steel or corrosion resistant steel.

The term can also mean "low alloy steel, i.e., steel with only a small percentage of those other metals; if the percentage is quite small, the effect is probably small.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

June 2016

Q. Hi, I'm jack and I'm 8 years old. I have a question too. I can't think of any examples of electrolysis and I really need at least one. Thank you

Jack l- uk, ahford

August 19, 2016

A. Hi Jack. Wikipedia lists a good number of examples.

But are you sure your teacher defines 'electrolysis' the same way Wikipedia does? If you answer a question without really understanding the question, it's a disservice to your own education and to your teacher. Are you positive that you can answer the question "What is Electrolysis?". If not, ask your teacher the question before you try to answer it. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

August 2016

Q. Dear Sir

I have to replace some old brass valves and unions, 1-inch size, connected to a carbon steel nipple that is welded to 12-inch carbon steel chilled water pipeline. I would like to know whether I have to use new brass fittings again or use stainless steel fittings on the existing carbon steel nipple ... my aim is to protect the nipple to avoid draining the system for re-welding jobs in case the nipple gets corroded.

Best Regards

- Jeddah-KSA, from Jordan

January 20, 2018

A. Ted, I think you are getting caught up in semantics. If you define rusting as/is the definition which is Fe + O = FeO2 you are correct. But many metals oxidize! Why don't you explain that to anyone? It's obvious from these posts that peeps are confusing rusting and oxidation. Why don't you explain that when metals tarnish, such as copper, it forms a greenish patina of copper oxide that forms on the outside surface of the exposed metal to atmospheric oxygen and moisture. This patina actually helps to protect the remaining underlying metal from future corrosion.

Brian wilstermannI'm a machinist - Dallas Texas America

March 11, 2018

Brian

If you read a number of relevant threads you will get an understanding of how many times Ted has done what you are asking for.

- Green Mountain Falls, Colorado

March 13, 2018

![]() Thanks Willie. New readers are likely to feel that too much has been left unsaid, while regular readers are probably bored to death by my repetitions :-)

Thanks Willie. New readers are likely to feel that too much has been left unsaid, while regular readers are probably bored to death by my repetitions :-)

But if that's about the worst problem I face, I've got a damn fine job! ... and I'm truly grateful to you and a few other guys for making it possible :-)

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

March 2018

Q. Hi, I am doing a science project and I need to figure out which household metal rusts the fastest. I need to get my hands on some of them FAST!

Alicia L [surname deleted for privacy by Editor]- Sydney, NSW, Australia

March 22, 2018

A. Hi Alicia. Aluminum foil and aluminum cans are available in many households. Coins are everywhere. Keys are getting less common in the digital age, but usually available. Steel cans are sometimes used for coffee or juices. Fastening hardware (nuts, screws, washers) are in everyone's junk drawer.

The two issues with most of these items will be using sandpaper to remove any coating on them so you have the base metal to work with, and finding out what metal they are made of. Most hardware is steel underneath the coating or plating on it. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. I'm in grade 8 I have a research on can all metals rust.

Abena A [surname deleted for privacy by Editor]Student - Ghana

October 18, 2018

A. Hi Abena. The page you are reading says that precious metals (gold, platinum, etc.) will never corrode, and that other metals like copper, brass, zinc, nickel, tin and aluminum will corrode but it's not called 'rust' because that word is reserved only for the corrosion product of iron.

So what do you think should be the next step in your research?

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

October 2018

Q. Hi, My name is Rylee, and I'm in seventh grade. I have to do a science project for the end of the year, and I wanted to do whether or not the temperature of water affects an object rusting. For this project, I have to make a research page about the topic I chose. We have to get all of our research before we start the experiment. I'm not quite sure what to research specifically. What would you research for this topic, that would be helpful, or interesting, or that I would need to know in order to do this?

Rylee Bigler- Blackfoot, Idaho

April 18, 2019

A. Hi Rylee. I probably wouldn't make it through the first period as a teacher, so I certainly can't presume to lecture teachers. But after reading thousands of student comments on their science projects on these pages for 24 years now, I know for fact that most young students are so eager to make the results of their experiments match their research that they almost always talk themselves into giving far too much weight to results that agree while eagerly dismissing as errors any results that disagree -- which means that they are inadvertently getting intensive training in "junk science" :-(

I would much prefer if you were allowed instead to do as one of our greatest physicists & teachers, Richard Feymann, suggested: guess at the answer, then do the experiments without predisposition, and only then research why you got the results that you did.

But, when you research this you will find that the speed of chemical reactions (like rusting) increases as the temperature increases because higher temperatures mean faster moving molecules, so more interaction and more likelihood of fast reactions. But on the other hand, the dissolved oxygen (which is what causes the rust, oxygen reacting with iron) decreases with increasing temperature (it bubbles out at higher temperatures). So the two factors are 'fighting' each other and the right answer is not at all obvious -- which makes a great case for your experiment.

You could put one of your experiment dishes in the freezer, one in the refrigerator, and one out in the open. But maybe put plastic wrap over all of them to minimize extraneous factors. If you have an old aquarium heater or other reliable heat source, you could also try warmer than room temperature. Best of luck!

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

April 2019

Q. Hi, I am making a science project and I was wondering what material rusts the fastest? Thank you so much!

Anne Swilley- Baltimore Maryland USA

March 23, 2020

A. Hi Anne. That's been the topic of this thread for 17 years and hundreds of postings :-)

Please read the first Q&A back on page 1 of this thread.

If you are having trouble reading and understanding the page, please have a parent read it and summarize what it says. It wouldn't be fair to the other students to keep drowning the page under more and more copies of the same Q&A, because each time the question is asked and answered the page gets longer :-)

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

March 2020

Q, A, or Comment on THIS thread -or- Start a NEW Thread