-----

Failure of railway compartment springs

Q. We manufacture helical springs and are used in the suspension system of railway compartments. Recently we witnessed failure of springs (it breaks) at the top end during assembly. Couldn't find a suitable reason. Any suggestions please?

bala k [surname deleted for privacy by Editor]engineer - Chennai, Tamil Nadu, India

2003

A. You have given no information about how the spring has failed, how it has been treated and what conditions it has been used in. There isn't even a picture of it! No-one will be able to answer this extremely important question because we don't know what is going on. I suggest you contact a reputable metallurgical consultancy and get professional advice based on examination of the real component. I would also do this before someone gets killed on your railways.

Trevor Crichton

R&D practical scientist

Chesham, Bucks, UK

2003

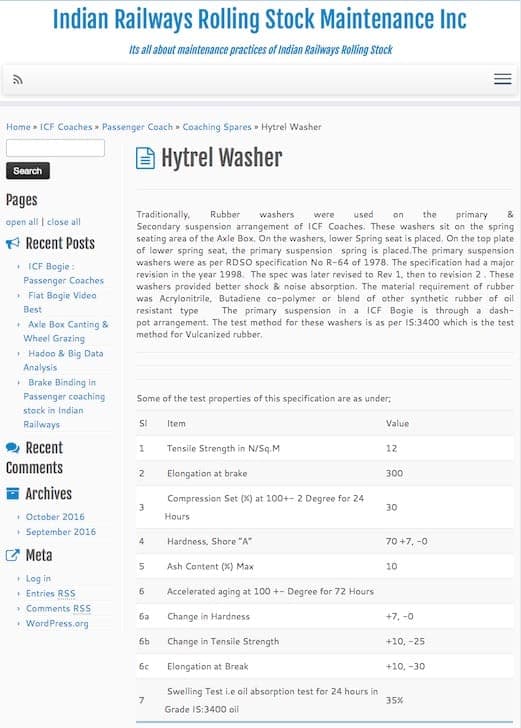

A. Springs are failing on indian railways because adequate clearance is not being maintained between the tip of the spring and the second coil. Also the rubber washers in use are of poor quality. Problem can be reduced by use of hytrel washers.

Soumendranath C [surname deleted for privacy by Editor]- Mumbai, India

2004

A. Further I would like to add that Indian railways have now switched over to the use of hytrel washers under and above the springs and this has resulted in a reduction of cases of spring failures on line.

Soumendranath C [returning]- Mumbai, Maharashtra, India

2007

Q. I am surprised the remarks posted by Soumendra C have not elicited any response so far. Perhaps he could elaborate a bit on this topic.

Vikas Sonak- Meerssen, The Netherlands

2007

Ed. note: We declined to print several followups where people asked Soumendranath to take the subject to private e-mail. This forum is for public discussions, and it is slightly rude to the other readers to try to disenfranchise them from the discussion that they've reading. Sorry, but we don't print either requests or offers directed towards taking these conversations private.

Indian Railways have switched over entirely to the use of Hytrel Washers successfully since 2006. Spring breakages though not quantified have reduced substantially.

S N Chakravarty- Bombay India

October 14, 2010

Q. Dear Shri Soumendra Nath and Chakravarty Ji,

Would you please explain technical rationale - as to how use of Hytrel washers have minimised spring breakages over Indian Railways.

- LUCKNOW India

January 7, 2017

Q, A, or Comment on THIS thread -or- Start a NEW Thread