-----

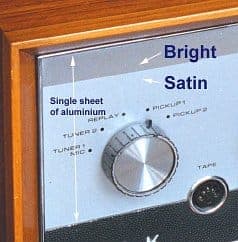

Obtaining both Bright & Matt Anodizing on the one sheet

I am undertaking a small production run of a aluminium panels for consumer electronic equipment.

Each panel requires a strip 3/8" wide of "bright anodized" area at the top, while the remainder of the panel is to be matte anodised. The boundary between the two needs to be a straight line for satisfactory appearance. Some suppliers have suggested that different pretreatment is required for each are, however the means to mask the "bright" area is not known.

Is this the correct approach (if so, what is used to successfully mask the bright area from the alkali etch), or is there another approach that will yield the required result?

Thanks,

Steve

- Melbourne, Victoria, Australia

2003

Although it might be a little more labor intensive for you...I would consider graining the entire part, then lightly bead blast (not sand) the part you'd like to be a matte finish. This, of course, would require that you tape (or make a masking fixture) the area of the part that you'd like to remain bright prior to bead blasting. This way, the anodizer could process the whole part normally without taking (and adding cost) extra masking steps.

Marc Green

anodizer - Boise, Idaho

2003

Q, A, or Comment on THIS thread -or- Start a NEW Thread