-----

Easy to apply high friction coating to cardboard

2003

Hello,

I am developing a machine which produce a composite material based on corrugated cardboard. The different steps in the process generate high friction between cardboard and its guiding parts. The cardboard has to be transported along this parts while only a few 10mm wide disks are available/possible to pull or push trough the cardboard. The contact pressure of the transporting disks to the cardboard is relatively low since the corrugation may not be squeezed. So, I'm looking for a coating material, which has a high friction to paper. At this moment the coating has to be applied on Aluminum. Since there is a small speed gradient of the paper to the disk a little slip, thus 'grinding' of the paper to the coating is unavoidable, even required. So the coating will wear fast. Consequently the coating has to be renewable rather regularly thus this may not be time consuming nor expensive. Most preferable is applying it by just spraying it on the disk or by painting it with a brush. A 10mm wide tape or adhesive film could also be a solution. If you have any suggestions to direct me in technique, material, cost, ... I would be pleased to hear about it.

Thanks in advance,

Wouter Neirinck- Hamburg, Germany

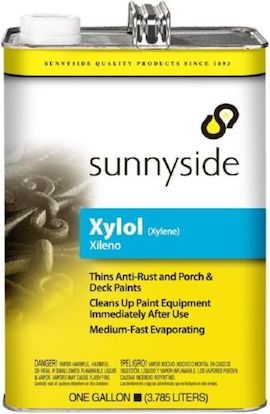

A. Anti skid for stair steps or for truck running boards would be perfect. In the USA, it can be found in several kinds of stores. It was tough to come by a few years ago. You might want to put a very thin coat of rubber cement-contact cement on the aluminum if you have a problem with failure of the adhesion to the aluminum. Xylene ⇦ on eBay or Amazon [affil link] works very well for removing the glue before you put a new piece on. Slow, but effective and it does not attack most paints.

James Watts- Navarre, Florida

How about using some small grinding wheels instead of the aluminum discs?

Tom Gallant- Long Beach, California, USA

Q, A, or Comment on THIS thread -or- Start a NEW Thread