-----

Electrocleaning solution (anodic) composition/additives info

A. From seeing the makeup of commercial electrocleaning solutions, They can vary.

Examples I have seen in certain products

Sodium Hydroxide 70%

sodium metasilicate

⇦ on

eBay

or

Amazon [affil link]

30%

Sodium Hydroxide 30%

Disodium Carbonate 70%

However there are other additives in small quantities being complexing/chelating agents which some cleaners do have and others don't.

- Perth, Western Australia

July 10, 2022

⇩ Related postings, oldest first ⇩

Q. Question regarding anodic cleaning: Several technical manuals state that additives can be dissolved in the cleaning solution to prevent oxide films from forming on the surface of the part being cleaned.

1. What types of chemicals are these "oxide inhibitors?"

2. What are common commercial names of such products?

My company has 2 "cycles" that are used to anodically clean a part. First, the part is anodically cleaned in an alkaline solution "to remove shop oils and dirt." Then the part is anodically cleaned in an acid solution. I am wondering what the roles are of the additives....

1. The alkaline bath uses "Oakite" [Chemetall], which I understand to be composed mostly of sodium hydroxide. Why is sodium hydroxide added to the bath? Is it primarily to remove grease and oils?

Thanks for any help.

Regards,

Dave Smith- Beltsville, Maryland, USA

2003

|

|

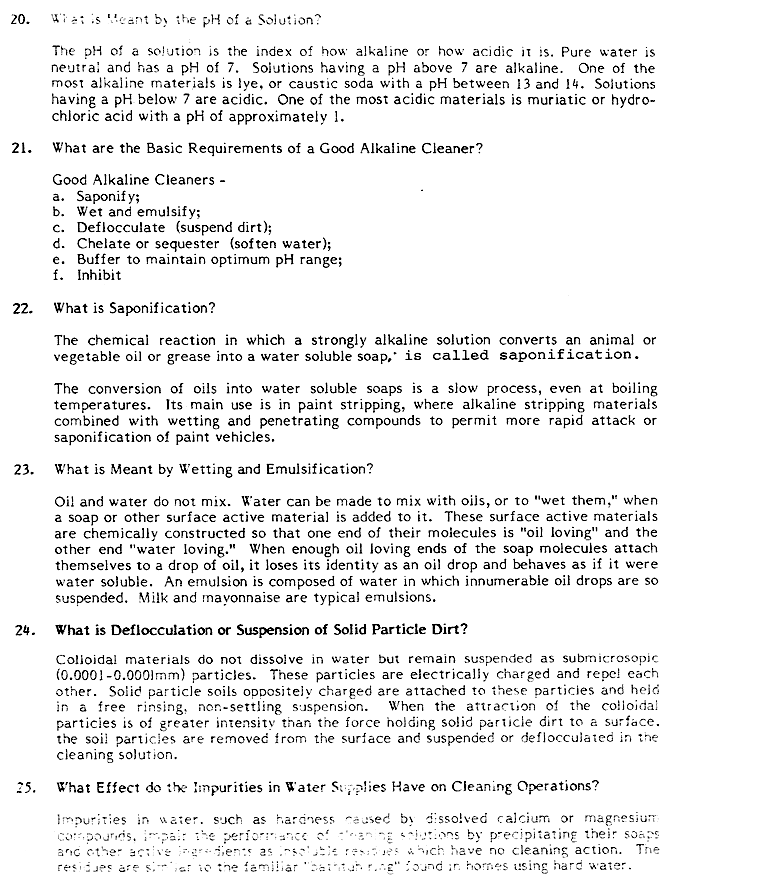

A. The best coverage of cleaning issues you will ever find is in one of the least expensive textbooks you'll ever find: "The Garden State Branch AESF Electroplating Course Manual" => I believe that the pH of alkaline cleaning solutions is the principal thing that prevents oxides from forming, but chelators (or complexors) play a significant role too. The principal role of sodium hydroxide, besides pH control, is saponification of animal fat into soap. Oakite is not a basic chemical, it's a brand name (Chemetall Oakite) of proprietary cleaning processes including anodic alkaline electrocleaners. Oakite would presumably be pleased to help you help you with the chemical balance of the cleaning bath.  Ted Mooney, P.E. Striving to live Aloha finishing.com - Pine Beach, New Jersey Ted is available for instant help or longer-term assistance. Unless you are a very high user of cleaning products, it is a waste of time to try to do your own formulations. I am a chemist and had a decent knowledge of most of the stuff in anodic cleaners but rapidly gave up the idea of making my own to save money. My time was worth more producing an end product and I could get tech help when something was not quite right. Sodium hydroxide is a common substance in an electrocleaner but is far from being a high percentage in a well formulated cleaner. Sodium gluconate or another derivative of gluconic acid is used as a rust (oxide) remover. It complexes the iron oxide so that it does not redeposit on the steel. The hydroxide saponifies oils , turns them into a soluble soap at high temps. High temp "melts" greases so that the hydroxide and other stuff can remove it. The first time a home brew fails, the boss will come looking for the lost soul that brought it into the facility even tho you may have gotten a nice bonus for the money savings a few weeks before. James Watts- Navarre, Florida |

A. Ted and James have given very good answers. I just want to add that sodium hydroxide provides the necessary conductivity to alkaline electrocleaners. (In acidic electrocleaners, the acids provide conductivity.)

Ken Vlach [deceased]- Goleta, California

Rest in peace, Ken. Thank you for your hard work which the finishing world, and we at finishing.com, continue to benefit from.

Q. Dear sir / madam

I am working alkaline zinc plating auto line; I will need electrolytic degreasing solution composition for pre-treatment preparation

plating shop employee - Chennai, Tamil Nadu, India

September 11, 2011

Q, A, or Comment on THIS thread -or- Start a NEW Thread