-----

Finish for Butcher Block Counter

Q. Hi,

I am making a solid wood, Mahogany or Maple, Kitchen counter top. I am trying to find the best Stain/clear coat system to use for it. I understand that the material should be FDA approved. I have been trying to find what an acrylic resin that a manufacturer mentioned. Will a standard Polyurethane work?

Any ideas?

Frank Maldari- Dix Hills, New York

2002

A. We have a maple "butcher-block" top as our kitchen counter. We finished it with 3 coats of polyurethane. Just the kind you get at the hardware store. We did not consider whether this was an FDA approved coating or not. Our belief was that the coating (after curing) would be inert enough for us.

Here's what has happened to it:

1) Our Stove top has a flange that covers the space between the counter and the stove top/oven. Within a year, there was a noticeable yellowing just behind the stove top (the sides have remained unchanged). It is an area about .25 inches x 8 inches. This corresponds to the place where most excess heat is vented from the oven. Now, 12 years later, that area is quite brown. Using the "self cleaning" utility of the oven increased the rate of change.

2) Massachusetts has the same variance in ambient temperatures that you probably see in NY. During the winter when the heat is on, wood tends to shrink a bit. In the summer, with greater humidity (and no air conditioning), it expands. The polyurethane coating failed at the seams where the wood butcher-block is laminated together. Not too much of a problem.... but if it gets wet or dirty there, it can seep into that break in the coating. We tend to ignore that... If it bothered me enough, I would probably sand the countertop down and coat it again with the same stuff.

Since the countertop is not sealed on the bottom where it sits on the cabinets, the changes in humidity allow it to expand and shrink. If you make your countertop, seal it and THEN mount it, it might be a bit more dimensionally stable. I would recommend more than the three coats that we put on ours. Or, you could refinish every five years depending on usage.

Ronna Erickson- Amherst, Massachusetts

2002

A. Bench top system. Fully seal before installation with an acrylic urethane wood sealer. Top coat with and acrylic urethane top coat. 4-5 coats. Should do the job or talk to a furniture refinisher.

Regards,

STEVE BEAUMONT- NEW ZEALAND

2002

A. We are installing a butcher block counter top (which, by the way, we purchased very inexpensively from IKEA), we will be finishing it with tung oil

⇦ on

eBay

or

Amazon [affil link]

- better I think than a polyurethane in that it's:

a) non toxic

b) is absorbed by the wood - doesn't give a "hard" coating over softer wood, which from experience, is prone to chipping over time.

Good luck!

- Connecticut USA

2004

Q. I am wondering how your counter top that is finished with polyurethane stands up to hot pots placed on the surface. I am considering polyurethaning my countertops, but am afraid that one misplaced hot pot will ruin the surface.

Donna Roberts- Finleyville, Pennsylvania

2004

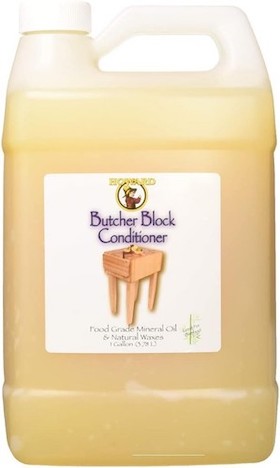

A. I have a butcher block section of counter and we use it to cut on as well as being able to put hot pots and pans on. I use mineral oil

The initial coat of oil soaks in relatively quicker than subsequent coats. My butcher block top is a section of rock maple that used to be a middle school woodworking bench and is at least 40 years old. This stuff is pretty dense, so after a couple of coats of oil in the first two or three months I have only had to put about one new coat a year. With this method you are also able to sand out any future imperfections or surface stains and then recoat with oil without having to worry about a noticeable patch if you were to go the polyurethane route.

- Massachusetts

2007

A. I have Oak butcher block and once every six months rub a hard coat of which is wax on the polyurethane. This keeps the water out pretty much perfectly.

Alex Anlyan- Montpelier Vermont USA

May 5, 2017

Q, A, or Comment on THIS thread -or- Start a NEW Thread