-----

How to finish wrought iron railings

Current question and answers:

March 1, 2021Q. Hello everyone I am a homeowner and I have commissioned a 'wrought iron'/mild-steel railing to be made for my front porch. I have read through many informative posts on this forum and many articles on the internet. Despite my research I still confused and worried about the corrosion performance my contractor has chosen for my outdoor railing.

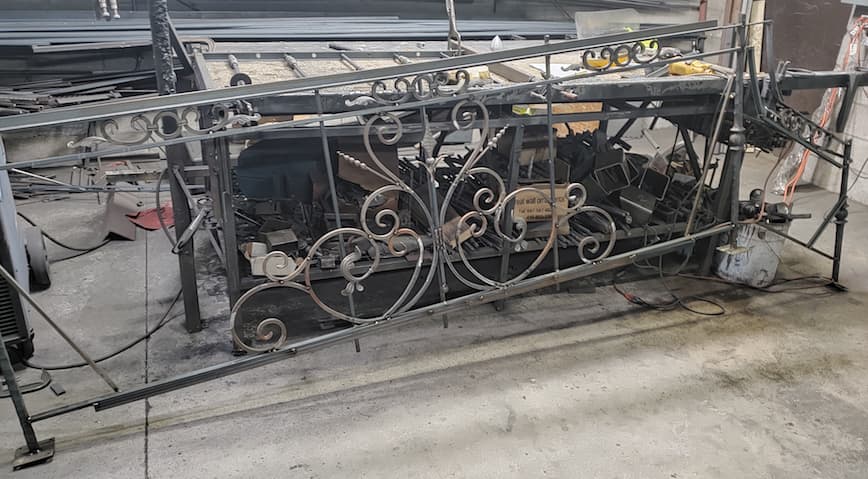

The current railing has components of ornamental steel parts manufactured in china mixed with some Canadian mild steel. Two leaves are cast iron because their steel counterparts were out of stock. It has a large center ornamental piece which consists of many scrolls with 1 x 1 picket design. I have attached pictures of the current unfinished railing and how the design should look once completed.

The railing will be placed outdoors in Toronto, Canada and will face conditions of winter and hot summers.

I have to give it a final inspection before it is sent off for finishing thus, I can change the type of corrosion protection. My contractor prefers to electroplate with yellow-zinc plating and powder coat with a gray zinc primer powder coat + outdoor primer coat in satin black on the railing. From reading online yellow zinc is zinc with a chromate treatment giving it better corrosion resistance. I have also read zinc plating is not ideal for outdoor applications.

The contractor states that after the plating is completed any areas that may cause future issues will be sprayed with Cold Zinc Spray such as the cast iron leaves and any welds done on-site before touching up with paint.

I have spoken to him about Hot Dipping with Zinc (HDG). He does not prefer it since the finishing is not the best and that small sharp particles can be left on the railings which may cut hands. He has pointed out that he must sand the railing if it is HDG; evenly sanding the railing is not possible and it's difficult to tell if too much zinc is taken off. He states this is not the case with plating. If I prefer I can HDG for an extra $500 dollars but have been told not to complain about the finishing since it will be difficult to sand the center ornamental scrolls and produce a smooth finish.

He has mentioned he has done the plating + powder coated combination for the last 6-7 years without any issues. In passing during an on-site visit he said to expect issues to occur around the 12 year mark. During our initial conversation he mentioned plating should last 18 years whereas HDG should last at least 25 years. The differences during our conversations on the plating effectiveness are causing me to worry and thus I am turning to the experts on this site to guide me in the right direction.

My questions are:

1) I would like to know if my contractors preferred method is sufficient to protect the railing. How long would this combination last and protect the railing for? If not, should I push for HDG given he does not prefer it?

2) A 5 foot section will need welding on install day to the main railing. Is cold spraying zinc on the welds followed by paint touch up sufficient protection?

Summary of Coatings:

Yellow Zinc plating + Zinc Cold Spray in Problem Areas + Gray Zinc Primer Powder Coating + Outdoor Powder Coating Black Satin.

Sorry for the length of this post. I tried my best to explain my situation. I was unable to get certain specifics with I spoke to the plating and powder coating companies. Your input and advice are great appreciated (article I found where a similar combination of plating and powder coatings were tested:

https://www.emerson.com/documents/automation/technical-article-corrosion-a-powerful-destructive-force-prevention-key-en-5467984.pdf

- Toronto, Ontario

A. Hi Yuvi. Sales pap doesn't count for much, but a reliable contractor's desire to do what he knows will work does. Besides, look around and you'll doubtless see that the biggest cause of aesthetic failure in the first several years is not corrosion but the paint/powder peeling off of galvanized surfaces. Please don't invite that by asking your experienced contractor to do something he is unfamiliar with :-)

When you read that zinc plating is not very good for outdoor exposure, that referred to bare zinc, not powder coated. I think what you are planning will be excellent.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

March 2021

![]() Thank you Ted for the quick response. I greatly appreciate you taking time out for your busy day and providing me with advice.

Thank you Ted for the quick response. I greatly appreciate you taking time out for your busy day and providing me with advice.

You are right about sticking to what my contractor has tried and tested. I should not compromise the finishing by straying from what he is comfortable with. His experience matters and I should trust it.

Often the simplest answer is the best and most logical one. I 100% agree paint and powder coating peeling is the cause of premature aesthetic failure in the first several years. Good bonding is important since it is the first line of defense against the elements.

Your vote of confidence in what I am planning is greatly appreciated. It has reduced my anxiety and stress regarding whether or not the correct corrosion resistance and finishing were selected. Now I can focus on the design aspects of the railing and make sure all is in order.

Once installed I will try to post some photos of the finished product!! Thank you Ted!!

- Toronto, Ontario

March 2, 2021

A. An interesting question! My first thoughts were to go for either hot dip galvanizing or powder coating, but you plan to have some on-site welding done, which will create minor issues with any coating! The HDG will certainly give you protection against rusting, but it will discolour over time and welding galvanised steel will always leave an unsightly area where the weld is. You could always paint the welded and heated areas with zinc paint, which may improve its looks. Galvanised parts look really good immediately after being dipped, with a wonderful pattern of large zinc crystals, but the zinc oxidises and weathers in air to create a dull grey surface. A good HDG part will probably outlive most people before it rusts and falls apart!

The alternative is a powder coating - this has many advantages, such as a wide choice of colours and a very corrosion resistant coating - it is certainly much better than conventional paints!. The main problem with your plan is that if the railings are coated before assembly, the welding will burn off the coating and make it look pretty nasty. The obvious path to take would be to change your method of assembly and used conventional fixings (nuts and bolts) to join the railings together after they have been coated, alternatively you may be able to find a powder coater who will do the coating in-situ and on site.

Trevor Crichton

R&D practical scientist

Chesham, Bucks, UK

March 18, 2021

![]() Thank you Trevor for responding to my question!!

Thank you Trevor for responding to my question!!

I would prefer HDG as well but my contractor is pushing yellow zinc plating and a powder coating combo. He did mention that rivets and bolts would not work for my case. I believe its because the posts are solid forged steel not hollow tubing.

My railing is L-shaped where a 5 foot section will be welded on to the front section you see in the photo above. I believe 3 small welds would be needed to be done attaching the double bar and bottom bar of the 5 foot section to the left post in the above photo. Hopefully the welds can be hidden and done on the back side of that post. The 5 foot section would be attached behind the front left post forming a L-shaped railing.

I see what you are saying regarding welding on site and how it will ruin the finishing. Perhaps using a finer welding apparatus could help. I would rather have everything welded before hand. I believe the issue is having a 5 foot horizontal section fit on his pick-up truck. I will be meeting with my contractor. Hopefully I can arrange for a larger truck so all welding can occur in his shop and the railing installed as one piece on-site.

I am concerned about the on-site welding melting the powder-coating off and whether touching these areas up with cold zinc spray + "spray paint" would match the powder coating and protect the railing.

I will update you after I meet with my contractor!!

- Toronto, Ontario

March 19, 2021

⇩ Related postings, oldest first ⇩

Q. I have wrought iron porch railing that is painted white. The problem is that it has become rusty and I need to know how I can easily remove the rust and repaint it. What type of tools will I need to complete this project?

Hollie B . [last name deleted for privacy by Editor]- American Fork, Utah

2002

Q. We have bought a home with a nearly new black wrought iron stair railing inside our home. We would like to paint the railing so it looks more like pewter. How do you recommend that we approach this project?

Thanks!

Mary Jane Gerhardsein- Columbus, Ohio

2002

A. This is fairly simple if labor intensive.

1. Wash clean

2. Remove heavy rust with a wire brush

3. Lightly sand painted areas and sand rusty areas until clean metal is visible. Try to "feather" into the rusty areas so they will not show as a low spot in the paint. 5. Clean off any sanding residues.

4. Using a metal primer, spot prime the rusty areas.It may be necessary to build up thickness if some areas are noticeably lower than the surrounding paint.

5. Prime full area.

6. Paint with a suitable paint. Materials such as Rustoleum will help retard formation of new rust.

process supplier - Great Neck, New York

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. I am working with wrought iron and would like to know the best ways to finish the things I make such as rustproofing for bathrooms and outdoors and for painting on the wrought iron with acrylic paints. Have heard about powdercoating, but sounds like it's not for a small operation like mine.

Can someone please give me the answers?

Joe Ackerman- Pilger, Sask, Canada

2003

A. Last time I was in Vancouver Canada I tried to find "OSPHO". I was building a new wrought iron railing at my wife's home there. I think the main ingredient is phosphoric acid...if you get to the USA, get some. It is applied 24 hours before painting the item and will keep items from rusting for year. If the item is small submerge it into the acid for a few minutes. It worked better for a 100% coverage.

Bill Mashburn- Hermiston, Oregon

2003

Q. I am planning on repainting some wrought iron railings in my dad's house what is the quickest way to do it. The old paint is chipping and there are some rust spots.

Lori Alescistudio 82 - Walton hills, Ohio, us

2004

----

Ed, note: please see also topics 7543,

24101,

26857,

32772, and

33964 for additional discussions on this topic.

Q. I HAVE A WROUGHT IRON RAILING INSIDE MY HOME. I WANT TO REFINISH IT. I WOULD LIKE TO DO A PEWTER FINISH. HOW WOULD I DO THIS?

KELLI LEE- LOVELAND, OHIO

2005

A. Hi Kelli. Pewter is a metal, not a paint color, so you can't get a true pewter by painting--only by sending it to an electroplating shop. But Krylon pewter ⇦ on eBay or Amazon [affil link] (and perhaps Rustoleum and other brands) of decorative metallic finishes in spray cans may well look good enough.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

2005

Q. I was told to use an oil based primer before painting my outside wrought Iron railing, so I went to the store and picked up primer however when I completed priming the railings it was only then that I realized that I had been using an interior oil based primer. My question is, being that I live in the northeast , is that primer going to be ok once I paint over that?, or should I paint over with another coat of exterior primer over it before painting.

John McGinty- Harrison, New Jersey, U. S.A

2005

A. If you don't want to be doing this again in another year, have someone remove the rail to have it sand blasted and powder coated.

Scott Davis- Spanish Fork, Utah

2006

Q. What is "powder coated"?

Jackie Ramey- Portsmouth, Ohio

May 21, 2008

aHi, Jackie. Powder Coating is a way of applying a coating that gives results very similar to paint; but instead of using a solvent, the part is sprayed with a fine powder of plastic, and then heated so that the powder melts and forms a continuous film over the part.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

May 21, 2008

Q. The wrought iron railing on my porch is peeling and rust is showing through. How do I refinish it? The railing is about 40 years old and was painted black.

Thanks for your help.

- Manchester, Connecticut

April 20, 2009

A. Hi, Sandra. Use a wire brush to remove any scale and heavy rust, wash it with a detergent, treat any exposed metal with naval jelly ⇦ on eBay or Amazon [affil link] , and paint it with any exterior black paint. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

April 21, 2009

Q, A, or Comment on THIS thread -or- Start a NEW Thread